Compact variable reduction ratio electromechanical actuator suitable for various working conditions

An electromechanical actuator and variable deceleration technology, applied in the field of electromechanical servo, can solve the problems of applications that cannot be complex, the reduction ratio cannot be further changed, and the layout scheme of the electromechanical actuator of the transmission cannot be adapted, so as to achieve intelligent control. , the optimal matching of health management, the effect of solving energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

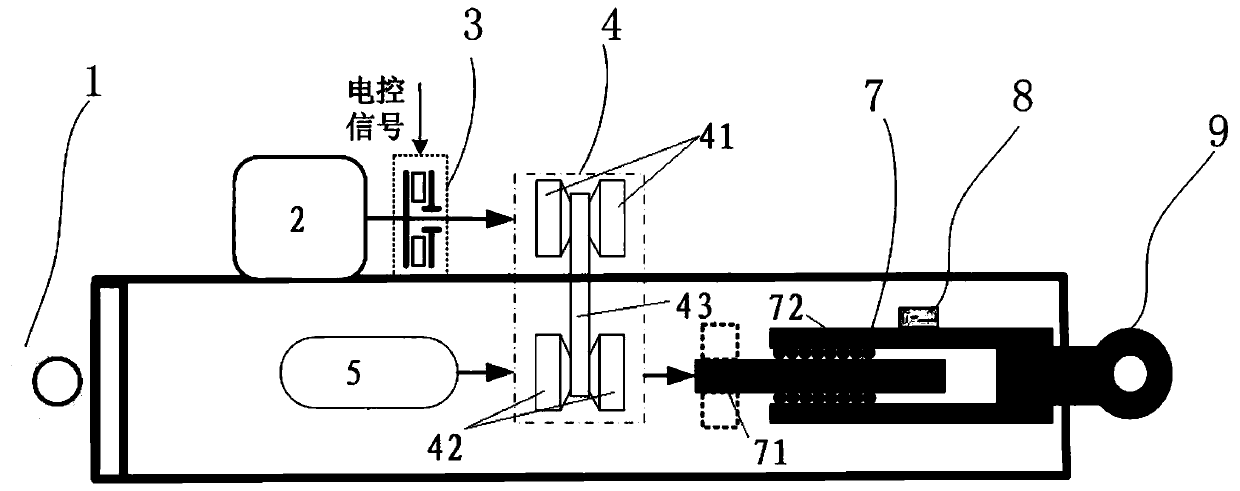

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] The purpose of the patent of the present invention is to provide a screw nut as a motor rotor telescopic double-redundancy electromechanical actuator, which realizes the integration and integrated design of the double-redundancy electromechanical actuator, and has short-term advantages compared with existing solutions. The technical characteristics of zero position, small size, light weight, high rigidity, high load capacity, and high precision are especially suitable for the performance requirements of servo actuation systems for military equipment in the aviation field, such as civil airliners, transport aircraft, fighter jets, and drones. In addition, the patented structure and working principle of the present invention can also be applied to electric control devices in the field of ships, which has broad application prospects.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com