Multi-procedure rice impurity-removal and dust-removal process

A multi-process, rice technology, applied in cleaning methods and utensils, cleaning methods using liquids, sieves, etc., can solve the problems of difficulty in guaranteeing the quality of rice, easy occurrence of dust, and time-consuming, so as to avoid excessive water absorption and deterioration. , to avoid the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

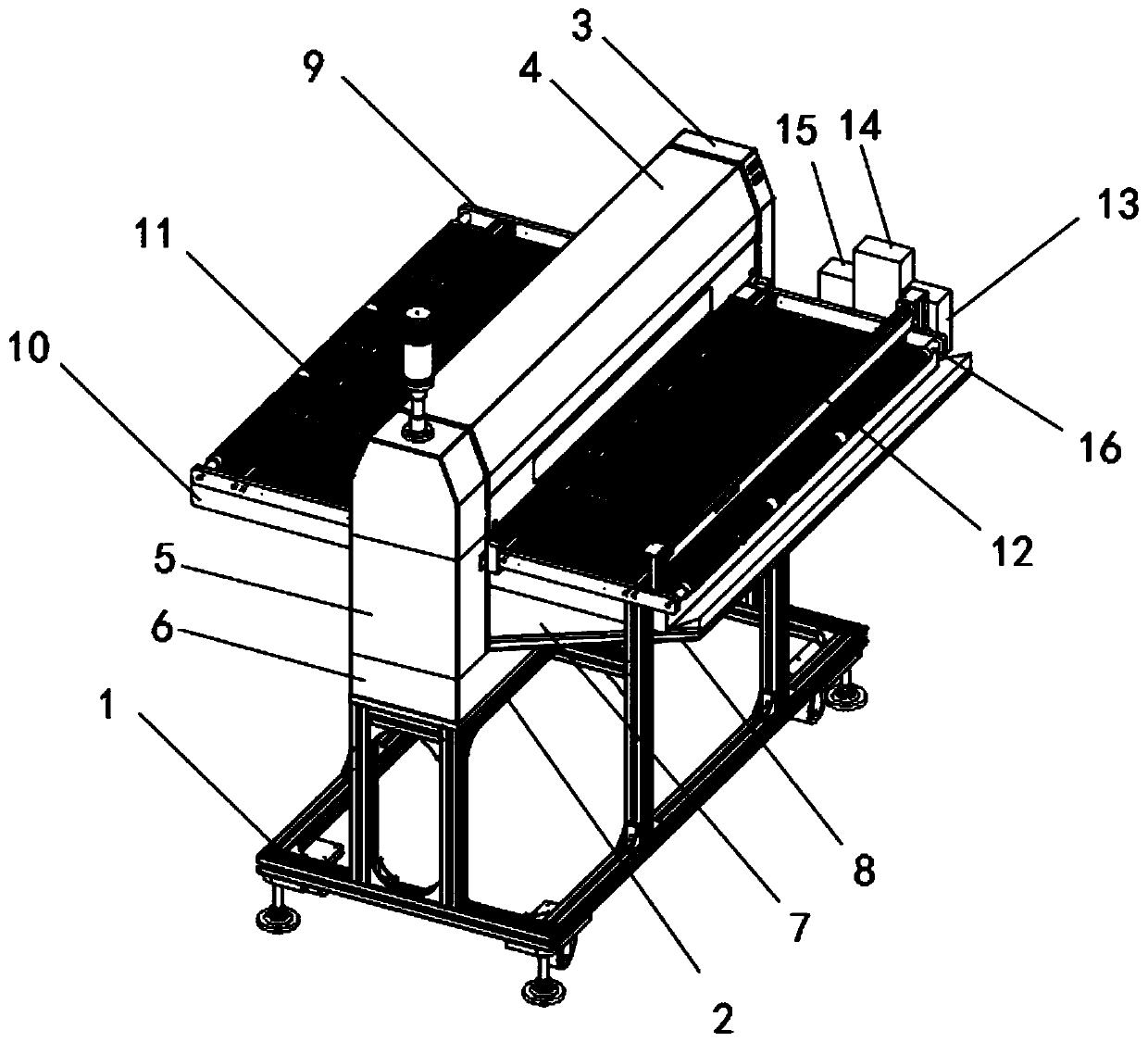

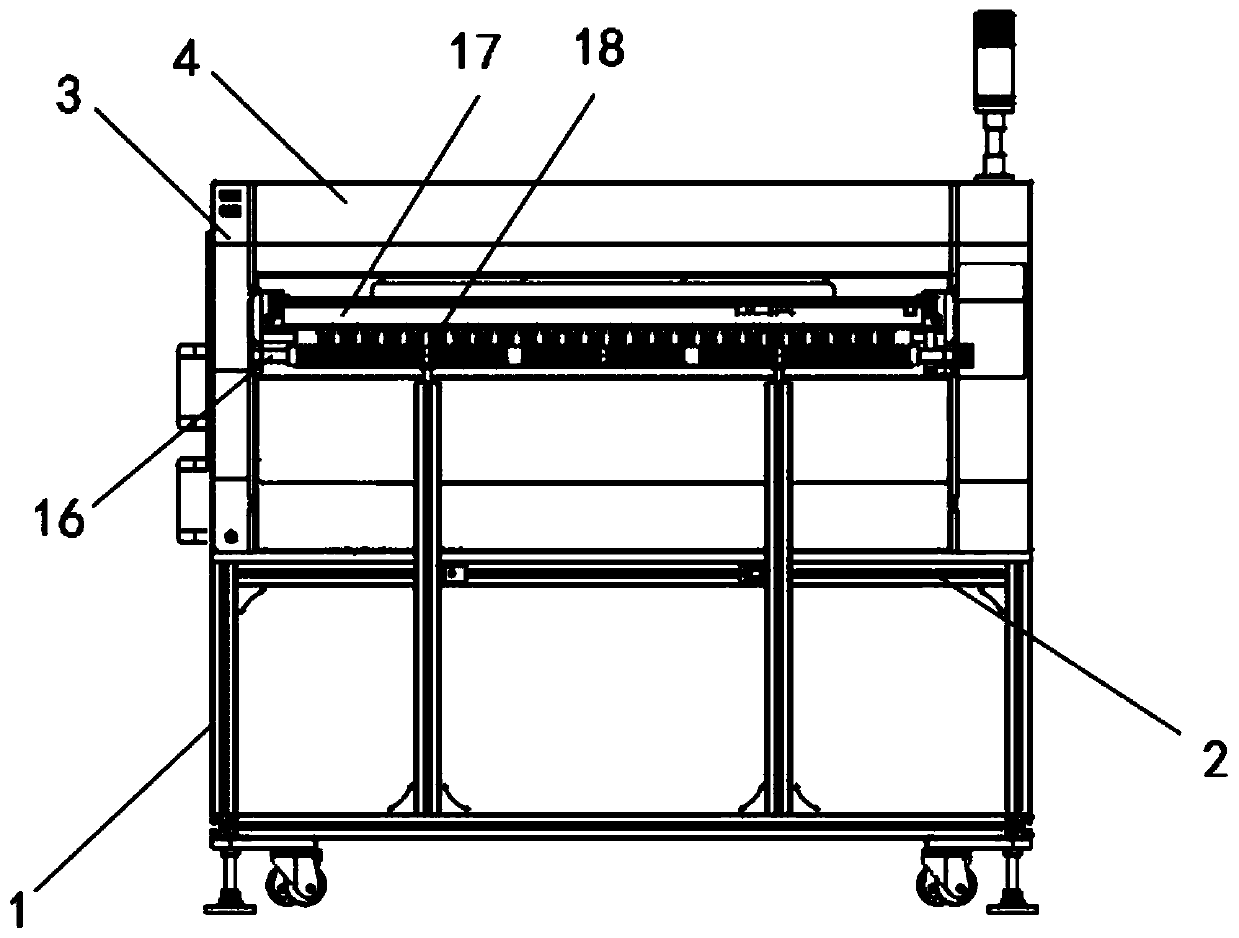

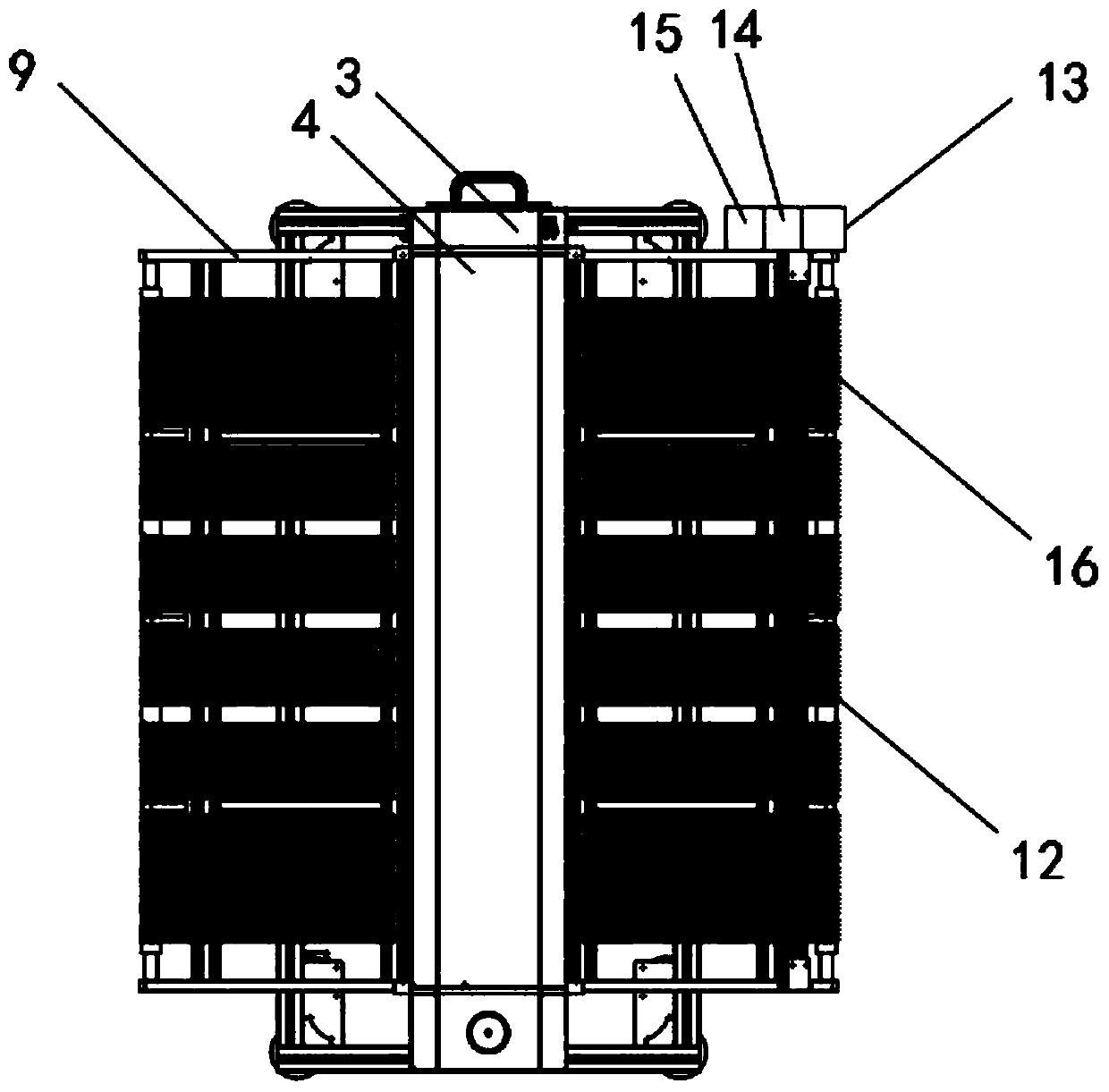

[0033] Such as Figure 1-8 As shown, a multi-process rice cleaning and dust removal process, the specific steps for the multi-process rice cleaning and dust removal process and the cleaning and dust removal equipment are as follows:

[0034] Step 1: pre-cleaning and dust removal treatment, put the rice that needs to be cleaned and dust removed into the cleaning and dust removal equipment, and spread the rice on the top of the end of the sieve plate 9 that is not equipped with the dust removal rack 12, start the side motor 13, use the side The motor 13 drives the rotating shaft 16 to rotate, thereby driving the screen 11 to rotate and transport the rice. During the transportation, the rice first passes under the top frame 4, and the paddle 18 is used to cooperate with the screen 11 to carry out pre-cleaning and dust removal for the rice. The dust and impurities fall into the collection tray 10, and with the rotation of the screen 11, the rice falls into the docking unloading bu...

Embodiment 2

[0045] When implementing the multi-process rice cleaning and dedusting process provided by the present invention, first carry out pre-cleaning and dust removal treatment, put the rice that needs to be cleaned and dedusted into the inside of the cleaning and dedusting equipment, and spread the rice on the sieve tray 9 without a dust removal rack On the top of one end of 12, start the side motor 13, and use the side motor 13 to drive the rotating shaft 16 to rotate, thereby driving the screen 11 to rotate and transport the rice. During the transportation, the rice first passes under the top frame 4, and the paddle 18 and the screen are used. 11 cooperates to carry out pre-cleaning and dedusting treatment on the rice, and the cleaned dust and impurities fall into the inside of the collection tray 10. With the rotation of the screen 11, the rice falls into the docking bucket 7 from the end of the screen 11 where the dust-cleaning frame 12 is set. Inside, during the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com