Welding torch module for film-type water-cooled wall surfacing

A membrane-type water-cooled wall and welding gun technology, which is applied to the characteristics of welding rods, welding equipment, welding accessories, etc., can solve the problems of high labor costs and low welding efficiency, and achieve the goal of ensuring welding quality, reducing labor costs and improving welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

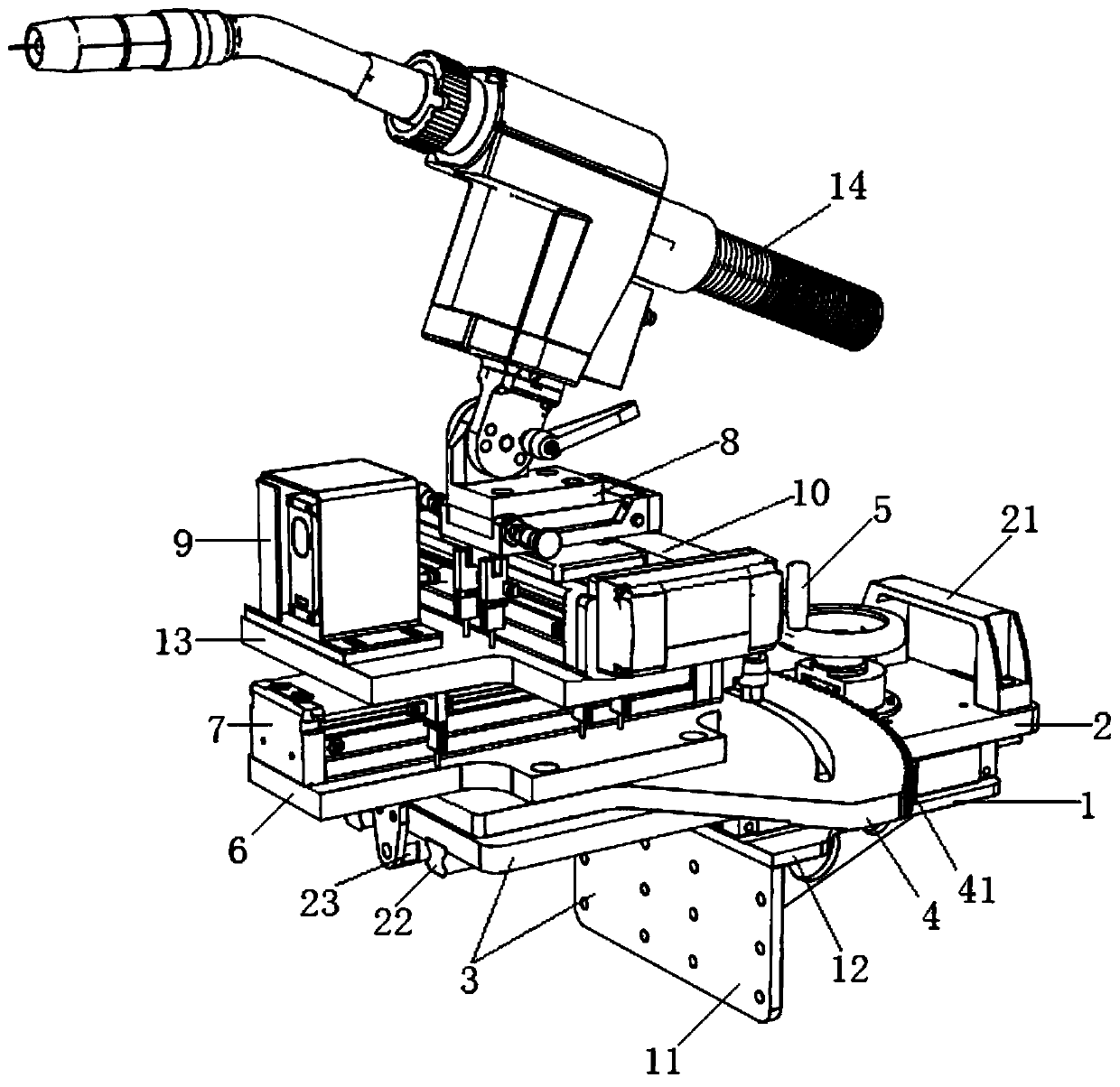

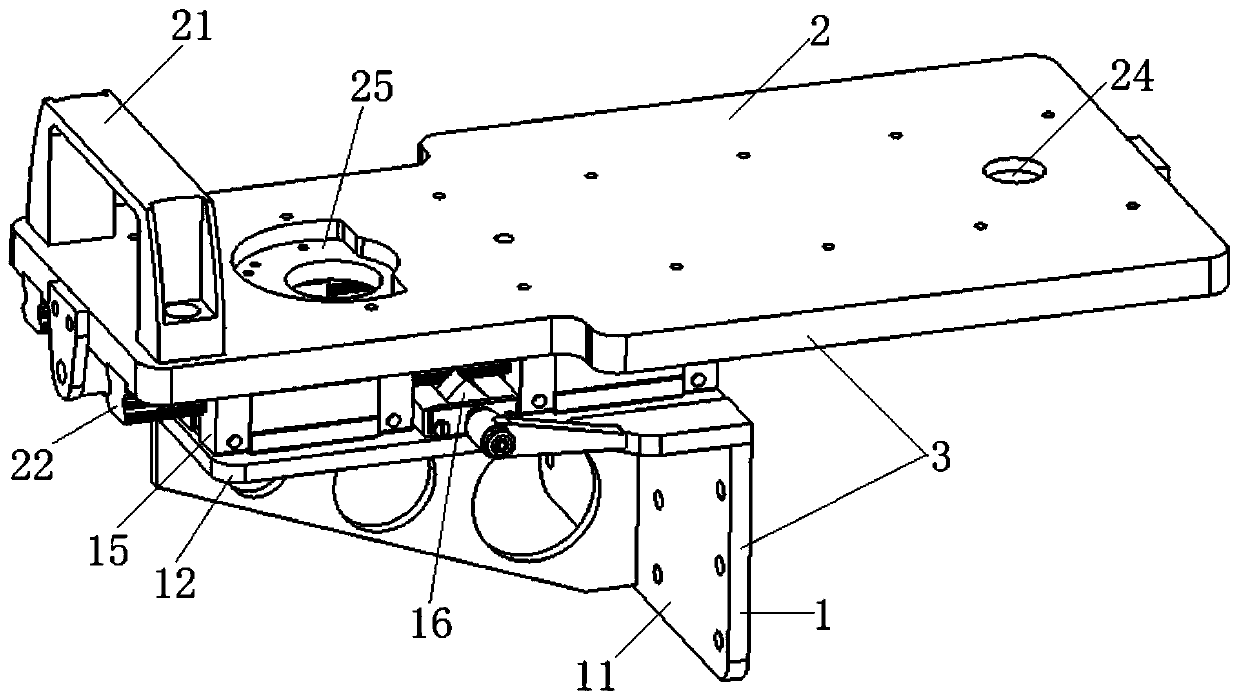

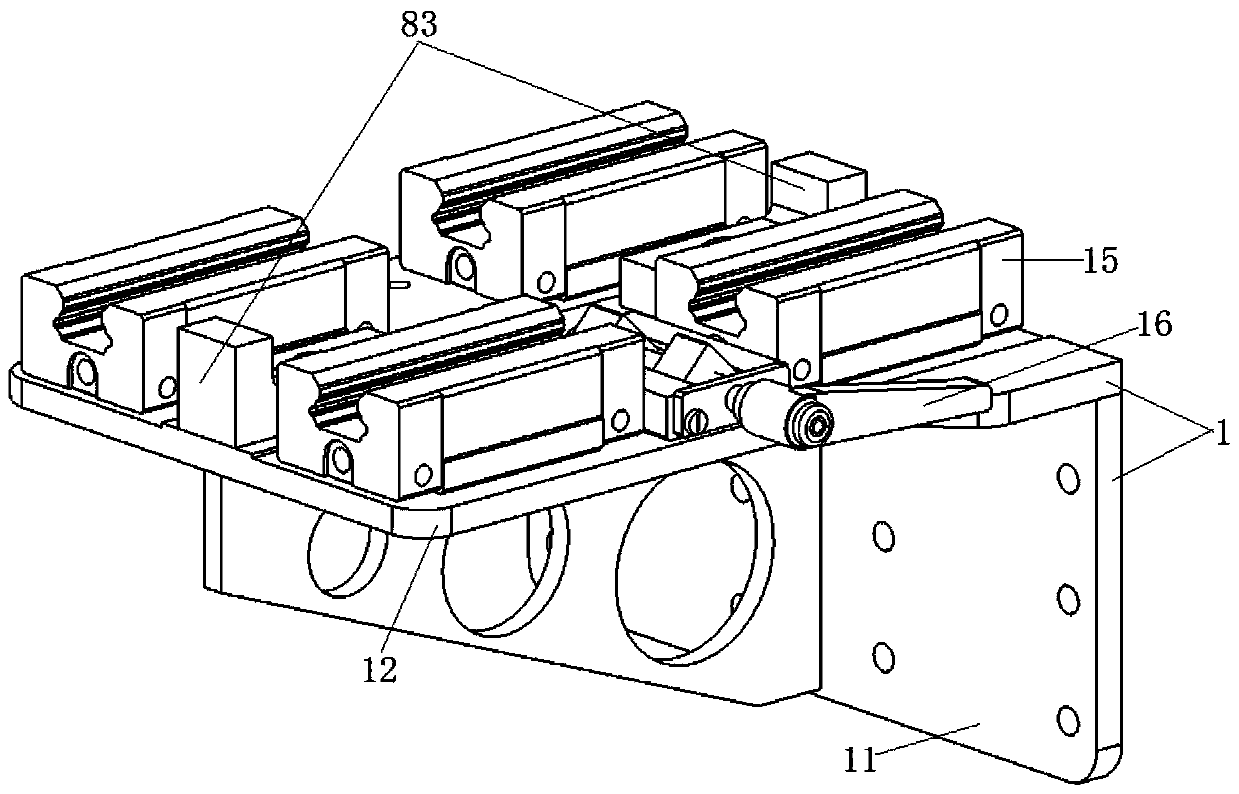

[0031] Such as Figure 1-17 As shown, the welding torch module of the present invention for surfacing welding of membrane-type water-cooled walls includes a forward and backward movement mechanism 3, a horizontal angle adjustment mechanism 4, a laser tracking mechanism 82, a servo swing mechanism 10, a vertical angle adjustment mechanism 8, and a welding torch 14; Wherein, the front and rear moving mechanism 3 includes an L-shaped mounting frame 1 and a moving plate 2 erected on the L-shaped mounting frame 1 and slidingly connected with the L-shaped mounting frame 1; the bottom of the moving plate 2 is provided with two symmetrical linear guide rails 22 and a Betwee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap