Laser welding feeding device for vertically welding concave characteristics on plate

A technology of laser welding and concave lettering, which is applied in the hydraulic field, can solve problems such as misalignment, dislocation, and gaps in the bottom plate, and achieve the effect of limiting the reverse pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a laser welding and feeding equipment for vertical welding of concave letters on boards.

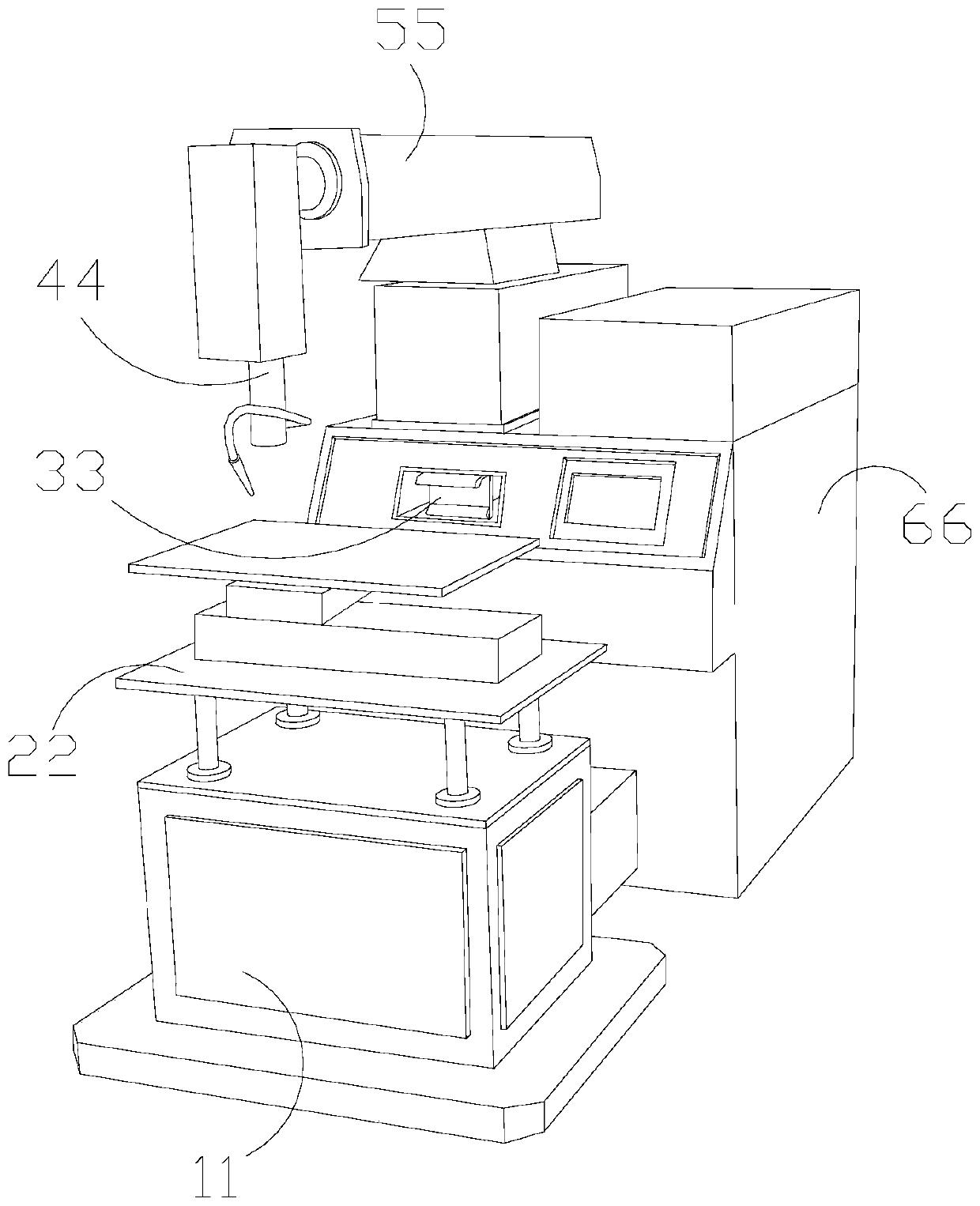

[0030] The upper surface of the bottom solid box 11 is equipped with a support plate 22, the hydraulic push plate 33 runs through the inside of the control box 66, the hydraulic laser welding head 44 is connected with the hydraulic pipe 55, and the hydraulic pipe 55 is installed on the control box 66. Box 66 upper surface.

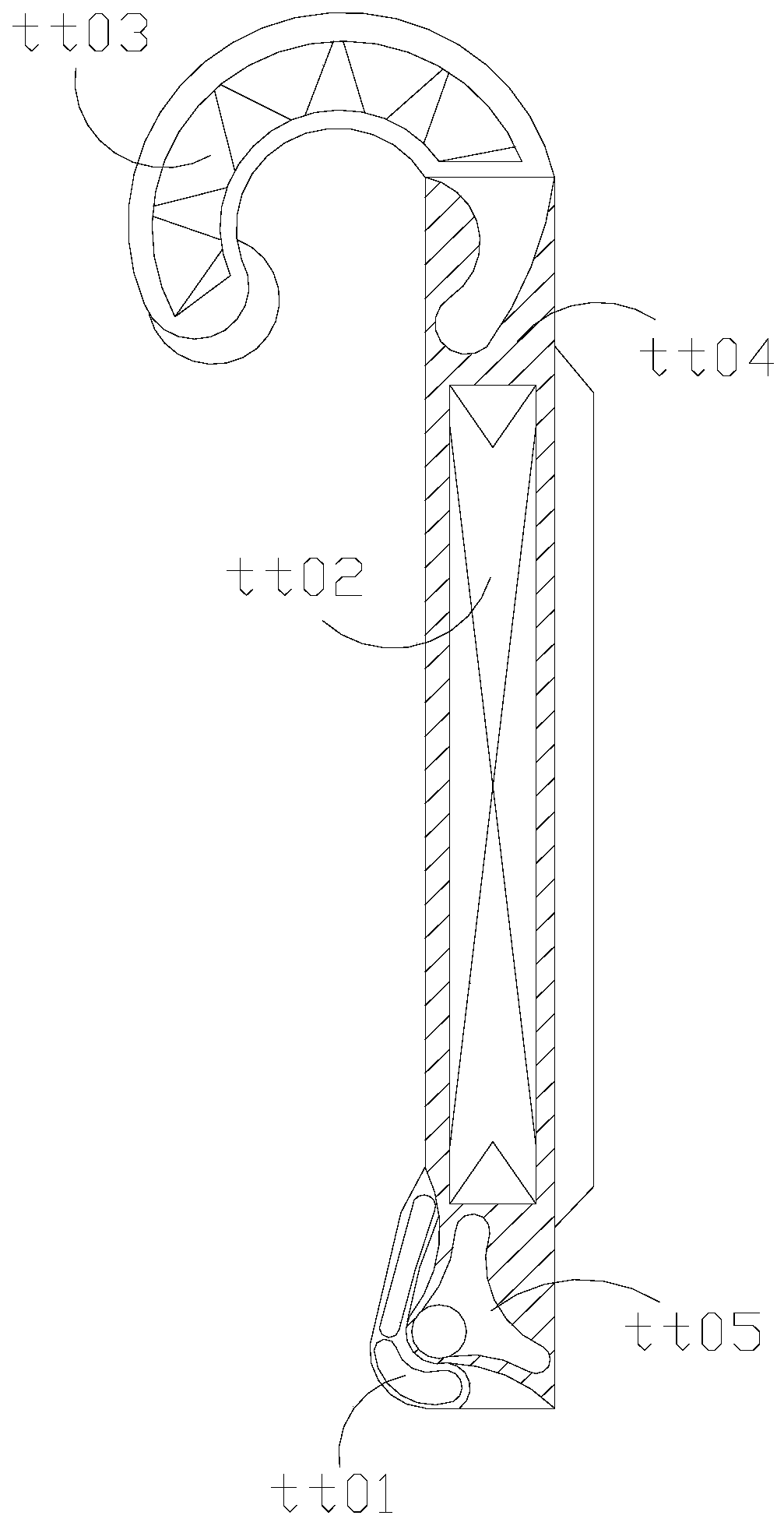

[0031] The hydraulic push plate 33 includes a top corner tt01, an inner solid core tt02, a homeopathic buckle tt03, an outer shell tt04, and a top convex bottom tt05. The top convex bottom tt05 is against the outer surface of the top corner tt01, and the inner The solid core tt02 is embedded in the outer shell tt04, and the outer shell tt04 is connected with the homeopathic buckle tt03.

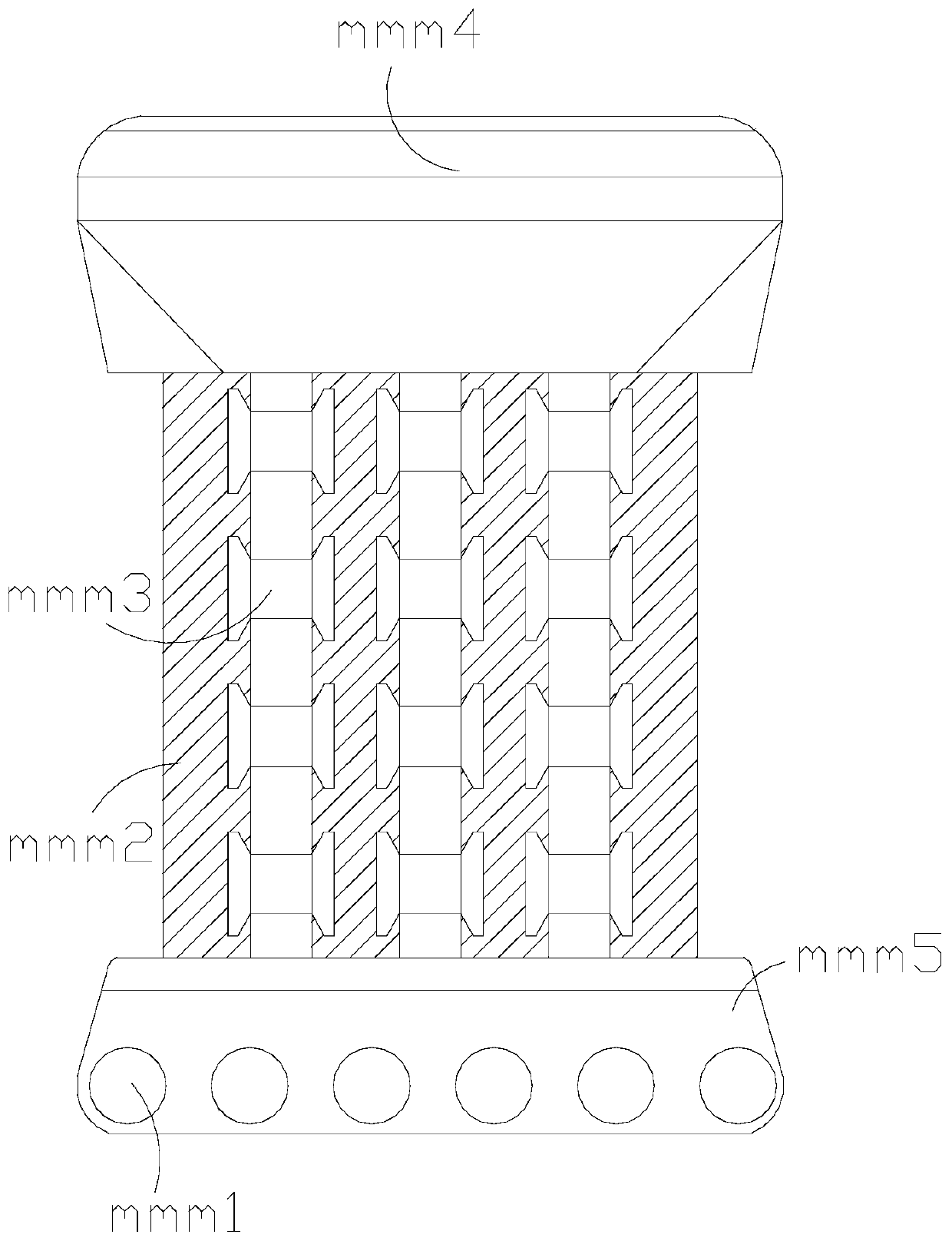

[0032] Wherein, the outer pocket shell tt04 includes an outer contact mmm1, a pend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com