Automatic robot assembling method for cylindrical-rectangular composite hole type part

A technology of automatic assembly and assembly method, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as difficult assembly strategies, damage to assembly parts and robots, and various contact states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

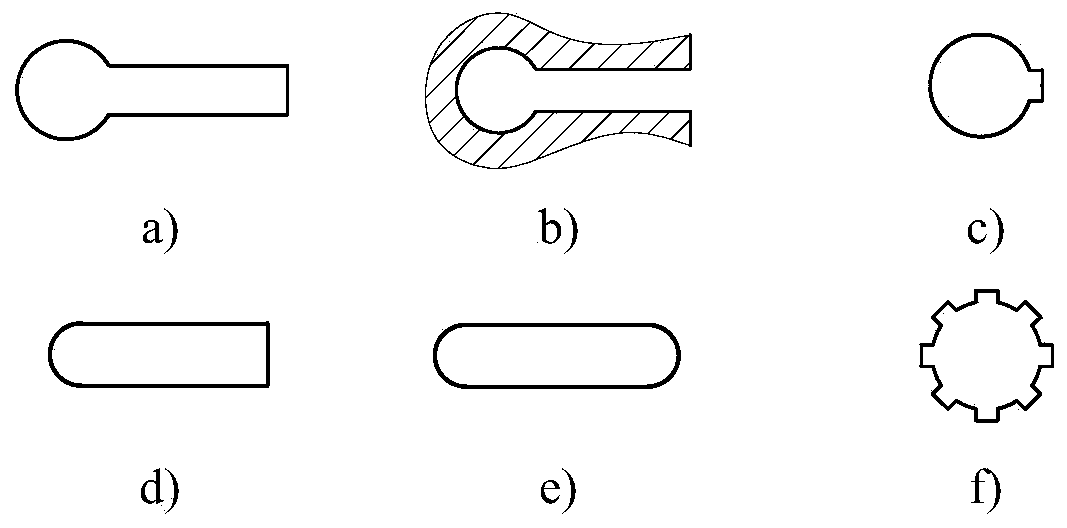

[0082] Embodiment 1: The assembly method is oriented to solving the problem of automatic assembly of hole-like parts with circular arcs, rectangles, straight sides and right angles in the geometric elements, and avoids assembly contact due to improper posture between shaft holes during the assembly process Damage to the assembly and robot due to excessive force. Such hole parts are called round-rectangular compound hole parts, and the matching shaft parts are called round-rectangular compound shaft parts. figure 1 Several common forms of such parts are given, including flat key hub, spline hub, A-type flat key hole, C-type flat key hole, special round-rectangular hole and so on.

[0083] Among the common parts in engineering practice, there are round-rectangular compound hole / shaft parts: splines, A-type flat keys, C-type flat keys, etc.

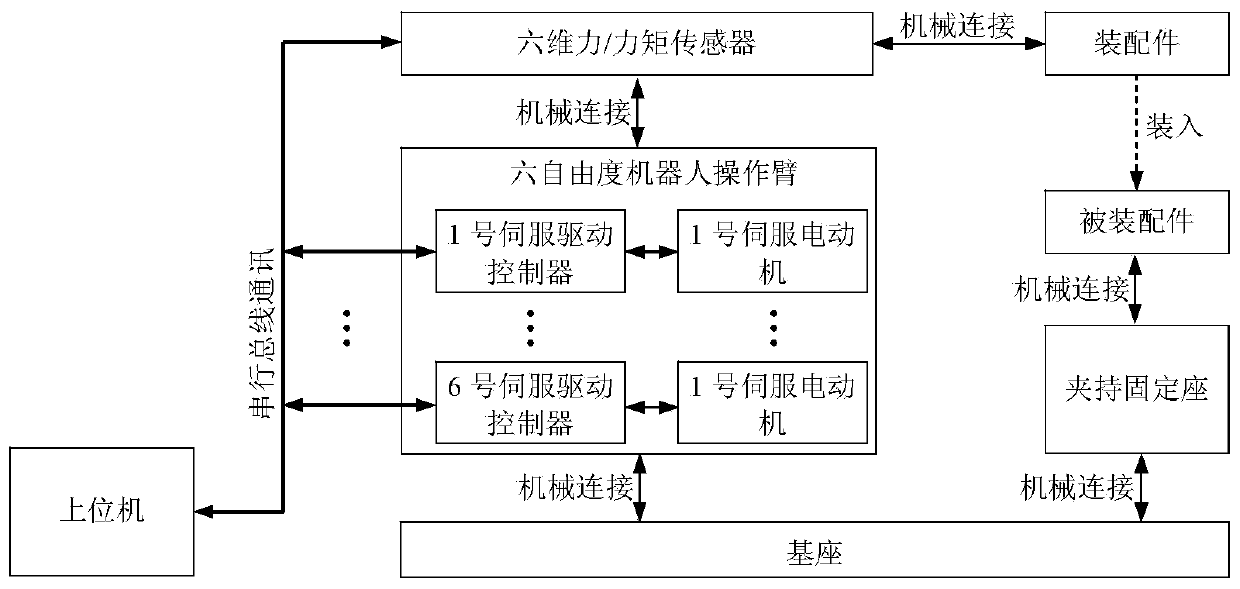

[0084] like figure 2 As shown, the automatic assembly system for round-rectangular composite hole parts using the assembly method is co...

specific Embodiment approach 2

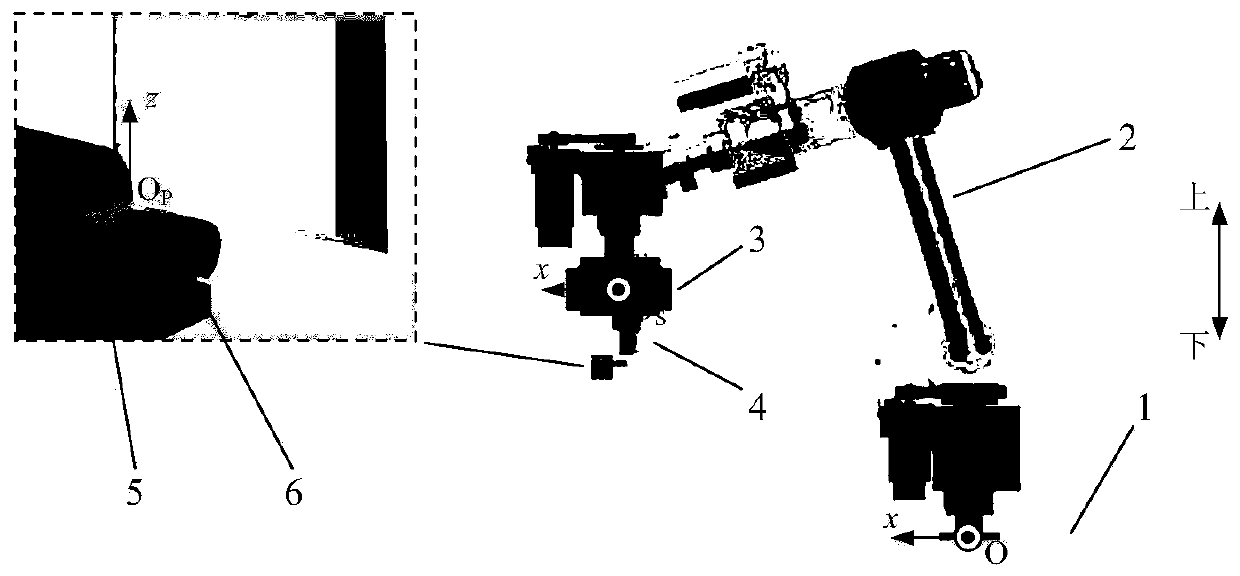

[0088] Specific embodiment two: In the assembly method of the circular-rectangular composite hole parts, the six-degree-of-freedom robot 2 needs to perform the position and orientation of the assembly part 4 according to the force feedback information measured by the six-dimensional force / torque sensor 3 Adjust it so that it is finally loaded into the circle-rectangular compound hole of the assembled part 6. The above assembly process is divided into three stages: approach stage, hole search stage, and insertion stage. The flow chart of assembly is as follows: Figure 4 shown, where F z Represents the z-axis force component measured by the six-dimensional force / torque sensor 3 (transformed into the ΣOP system), h represents the distance of the assembly part 4 inserted into the assembled part 6 along the z-axis, h d and h max are the insertion depth discrimination thresholds for hole search completion and assembly completion, F max is the threshold of contact force.

[0089] ...

specific Embodiment approach 3

[0095] Specific implementation mode three: In the automatic assembly system applying the assembly method of the circular-rectangular composite hole parts, it is necessary to construct such Figure 5 For the force / position hybrid control system shown, define X=[x,y,z,θ P1 ,θ P2 ,θ P3 ] T is the pose vector of assembly 4, where x, y, z are ΣO P Position coordinates in the base coordinate system ΣO, θ P1 , θ P2 , θ P3 ΣO P The three Euler angles of the system relative to the ΣO system; θ=[θ 1 ,θ 2 ,θ 3 ,θ 4 ,θ 5 ,θ 6 ] T and τ=[τ 1 ,τ 2 ,τ 3 ,τ 4 ,τ 5 ,τ 6 ] T are respectively defined as the joint angle and joint driving torque vector of the six-DOF robot 2, where θ i and τ i (i=1,2,...,6) respectively represent the joint angle and driving moment of the i-th joint; S f e is a six-dimensional force / torque sensor 3 in ΣO S The raw data of force rotation (including three force components and three moment components) measured in the system, P f e will be S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com