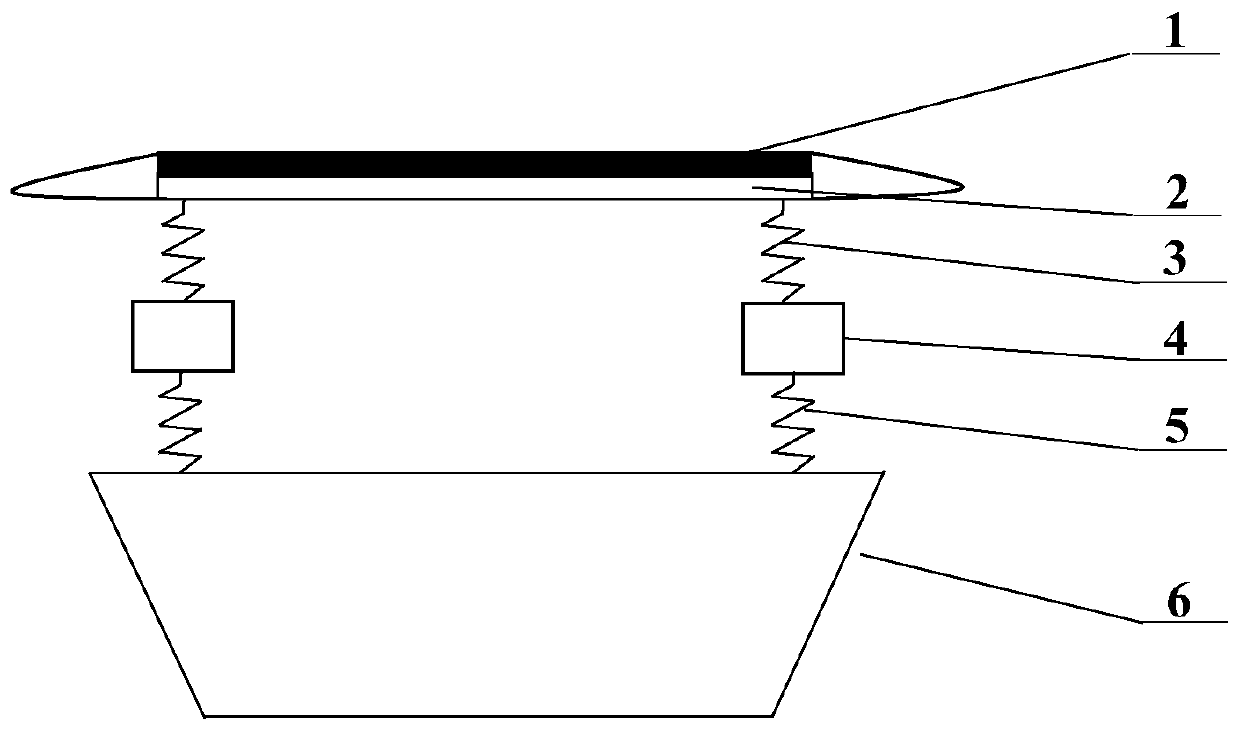

Pantograph structure

A pantograph and bow head technology, which is applied in the field of electrified railway pantograph-catenary system, can solve the problems of low optimization degree and severe pantograph-catenary vibration, and achieve prolonging service life, suppressing pantograph-catenary vibration, and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

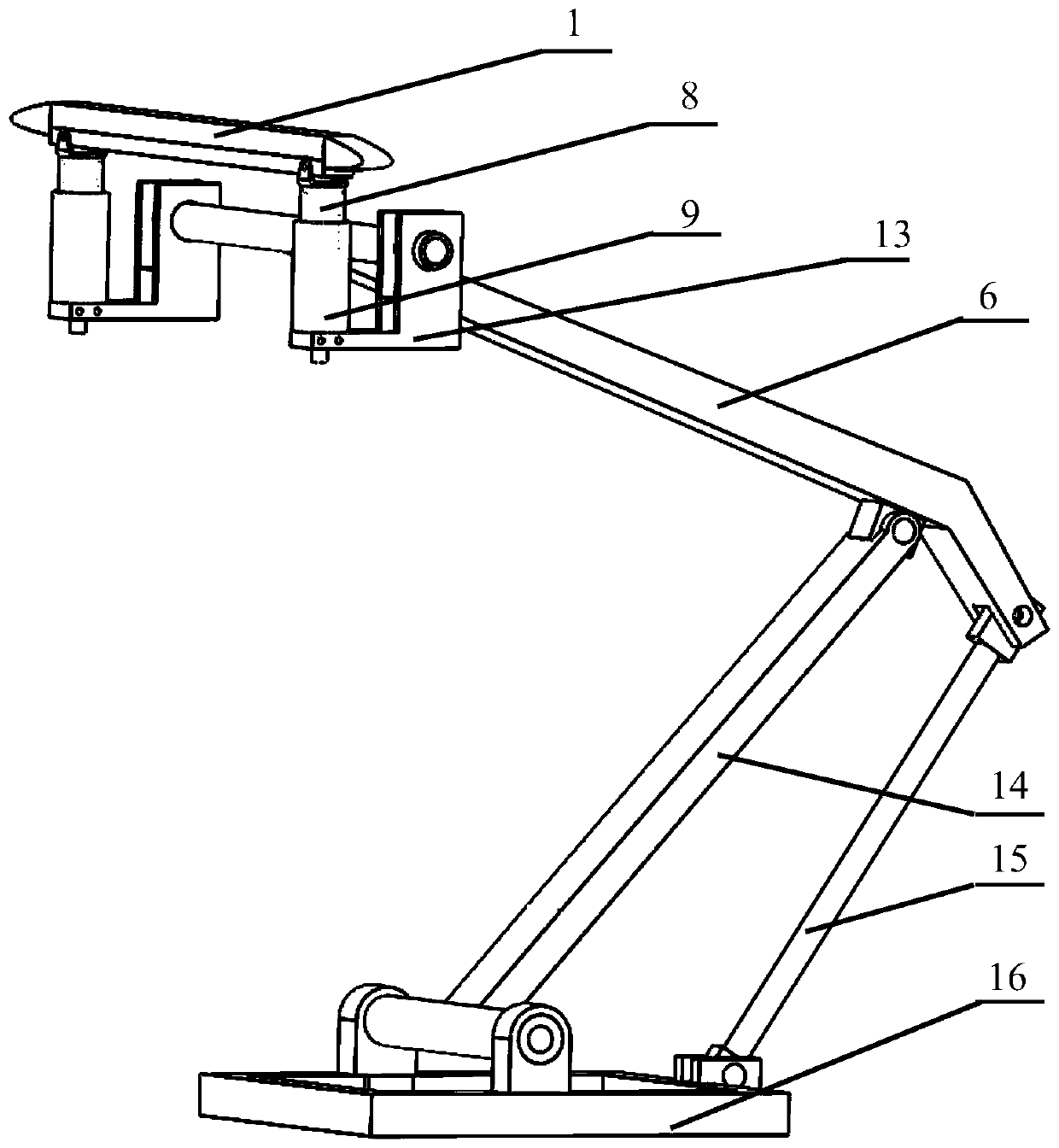

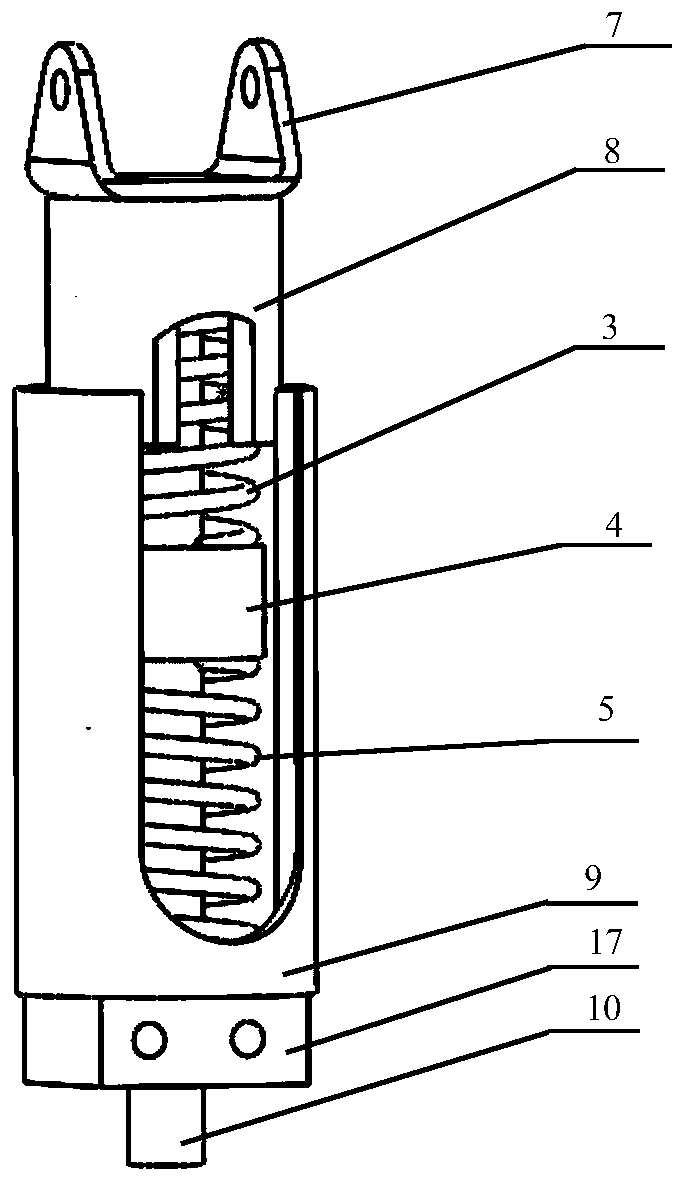

[0025] The present invention will be further described in detail below in conjunction with the examples, and the specific examples described here are only for explaining the present invention, rather than limiting the present invention. A pantograph structure, comprising a carbon block 1 for a skateboard, an aluminum support for a skateboard 2, an upper arm 6, a lower arm 14 and a pantograph base 16, the upper end of the lower arm 14 and the lower part of the turning point at the tail of the upper arm 6 The hinge support is hinged, and the lower end is an inverted "T"-shaped structure, and the two ends of the inverted "T"-shaped crosspiece are hinged with the lugs at the front of the middle and front parts of the pantograph base 16; the upper end of the tie rod 15 is connected with the upper arm 6 The hinge support at the rear end is hinged, and the lower end is hinged with the hinge support in the middle of the rear transom of the pantograph base 16; the upper end of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com