Double-layer rod feeding box automatic rod feeding device

A rod device and automatic technology, applied in drill rods, drilling equipment, earth-moving drilling, etc., can solve the problems of large stroke of rod-changing cylinder, low rod-changing efficiency, unstable lifting, etc., to solve the existing technical problems, avoid The effect of using defects and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] At the present stage, when the non-excavation drilling rig replaces the drill pipe for the drilling rig during the working process, it is often due to the asynchronous lifting and unsteady lifting of the oil cylinders on both sides of the double-stage cylinder used, resulting in an uneven rod changing action. Therefore, the present invention provides a double-deck rod box automatic rod-up device to solve the above problems.

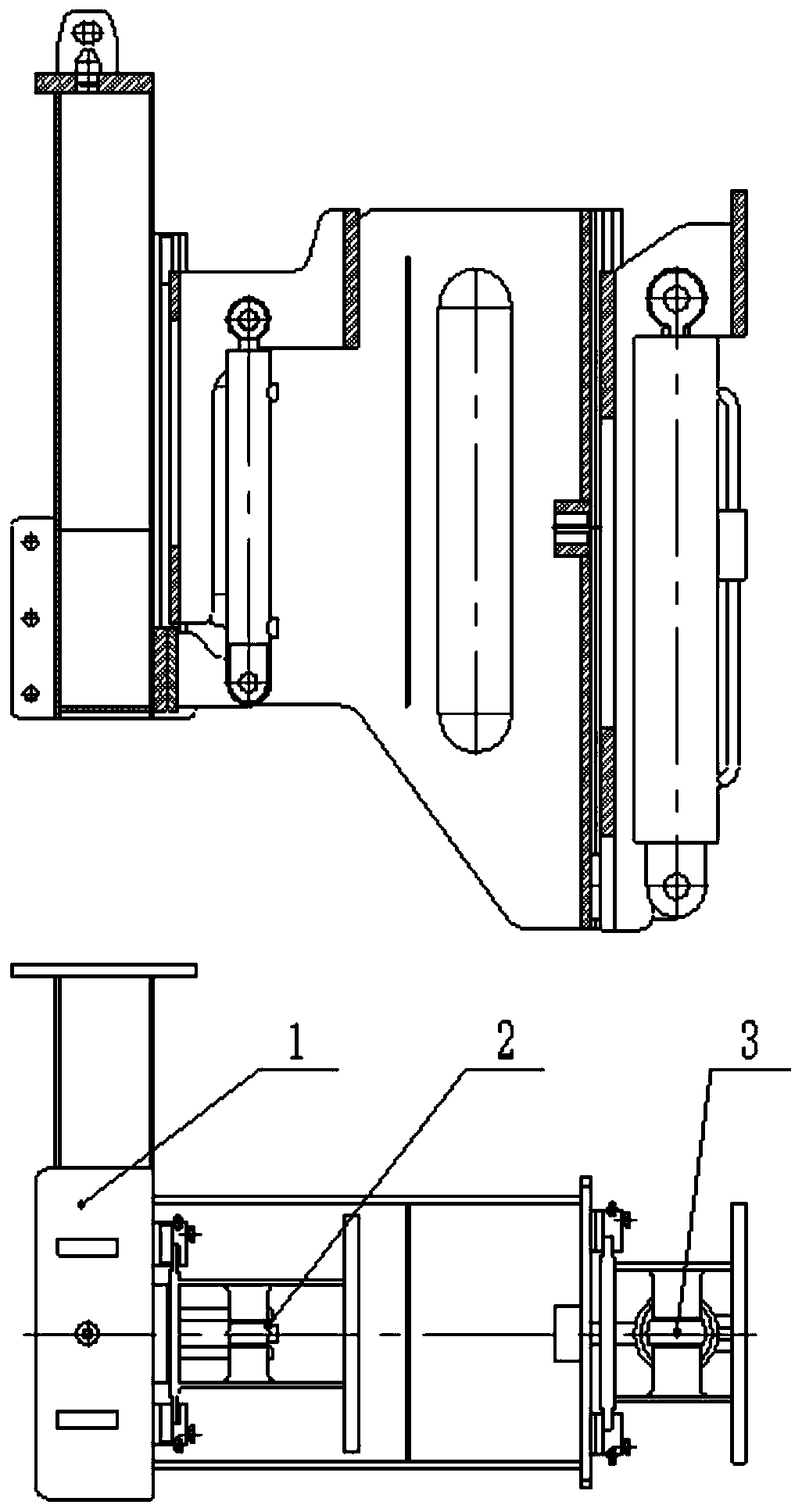

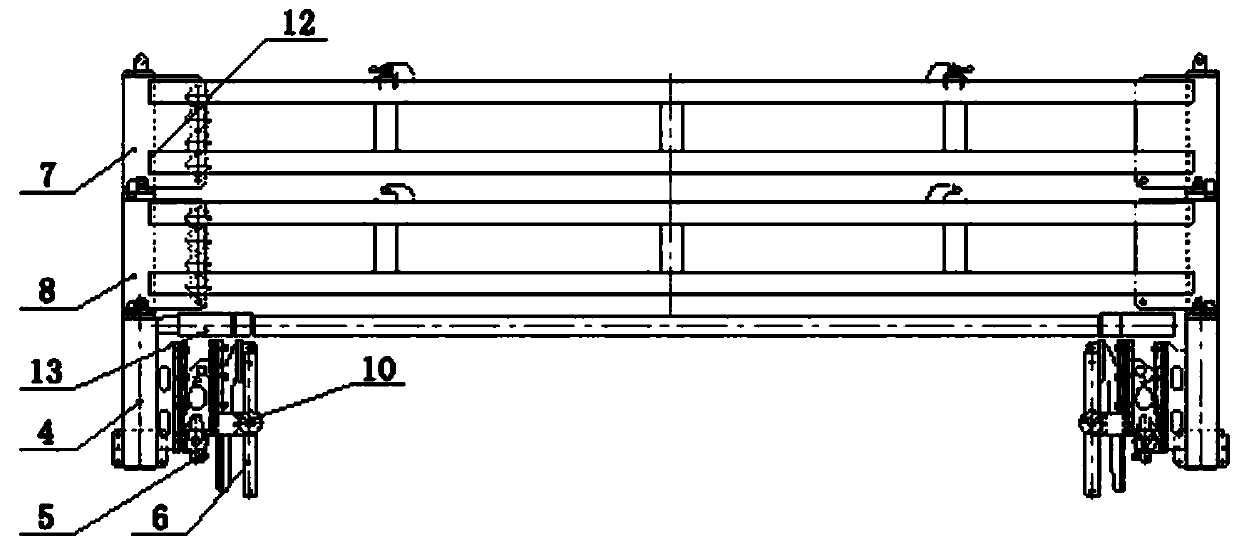

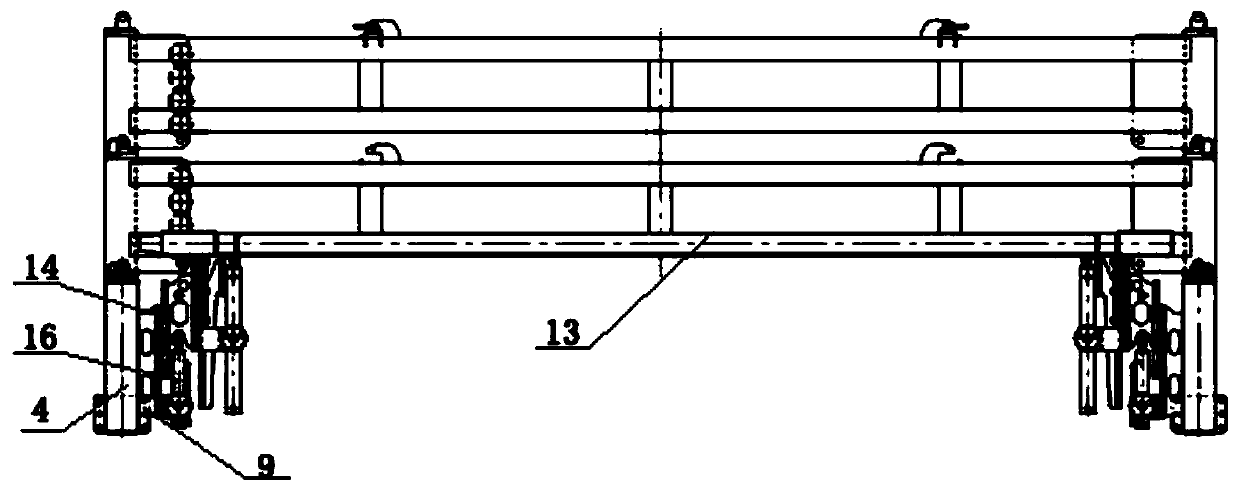

[0042] figure 1 It is a structural schematic diagram of the double-layer upper rod box connecting rod in the background technology; figure 2 It is a structural schematic diagram of the automatic rod-up device of the double-layer rod-up box of the present invention; image 3 It is a schematic diagram of the lifting mechanism of the present invention rising to the highest point; Figure 4 It is a schematic diagram of the rod changing mechanism in the present invention rising to the highest point.

[0043] Please refer to Figure 2-4 , a double-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com