Railway wheelset rolling bearing running-in machine pneumatic wheelset pressing and positioning mechanism

A rolling bearing and positioning mechanism technology, which is applied in mechanical bearing testing, railway vehicle testing, radiation pyrometry, etc., can solve the problems of inaccurate temperature detected by infrared temperature measuring probe, easy vibration of bearing position, and poor use effect, etc. , to achieve good running-in effect, stable bearing position and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

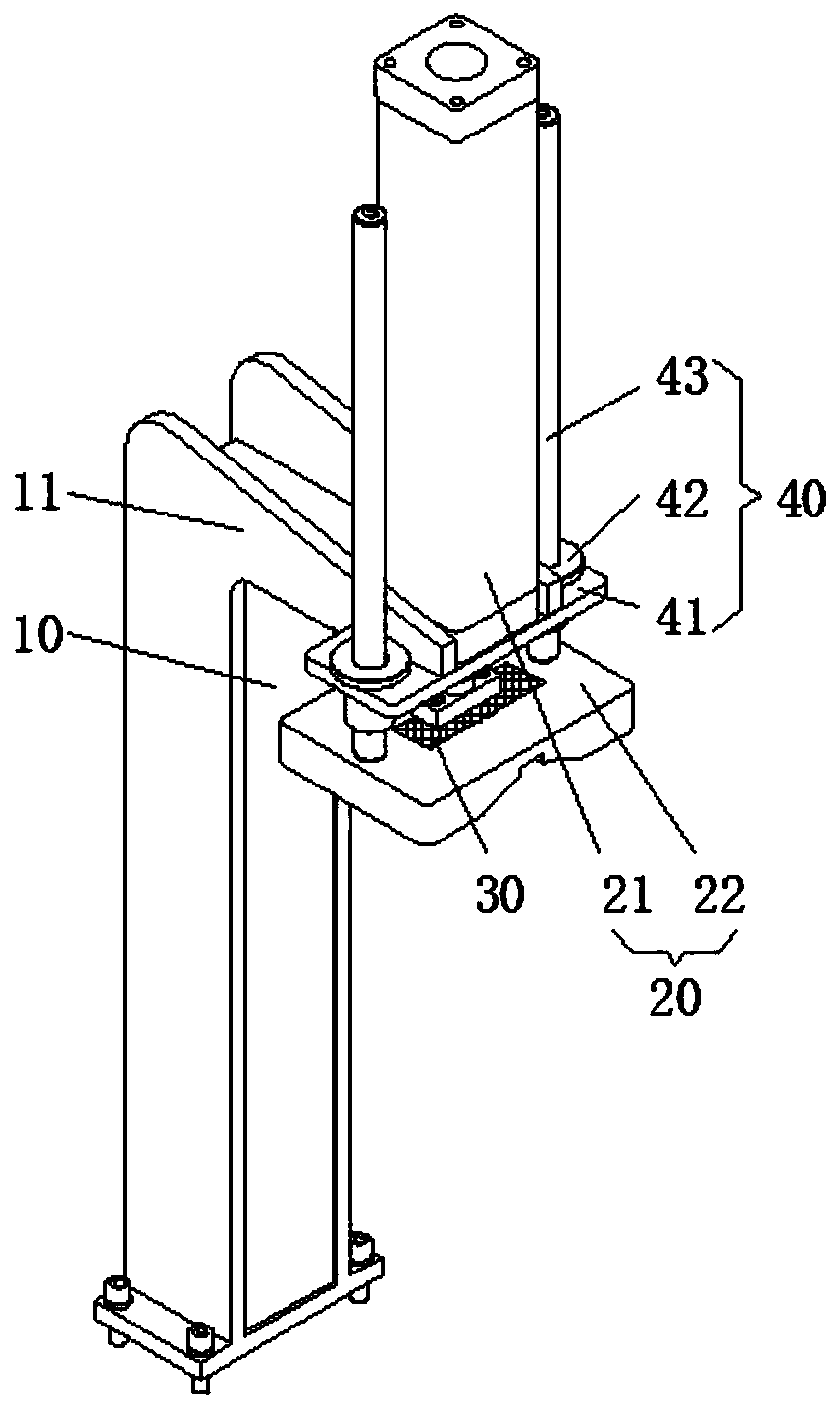

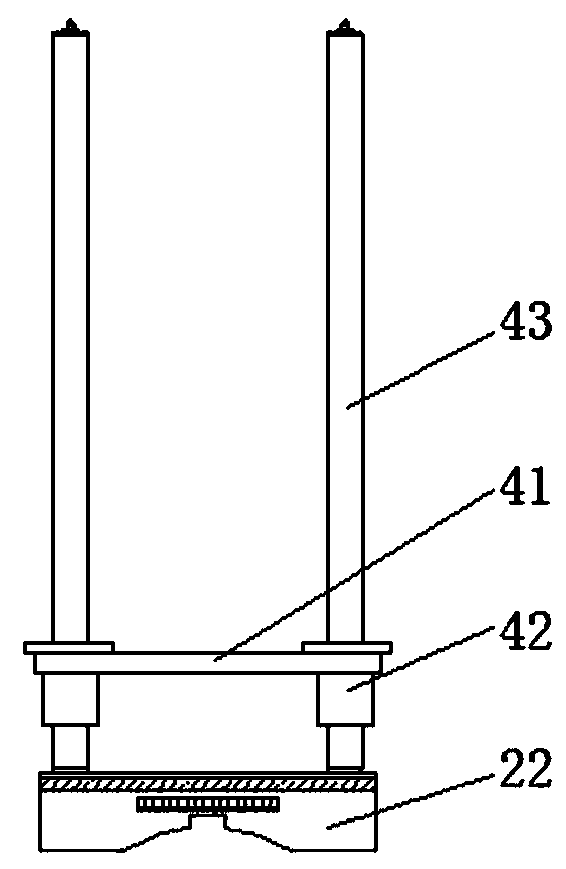

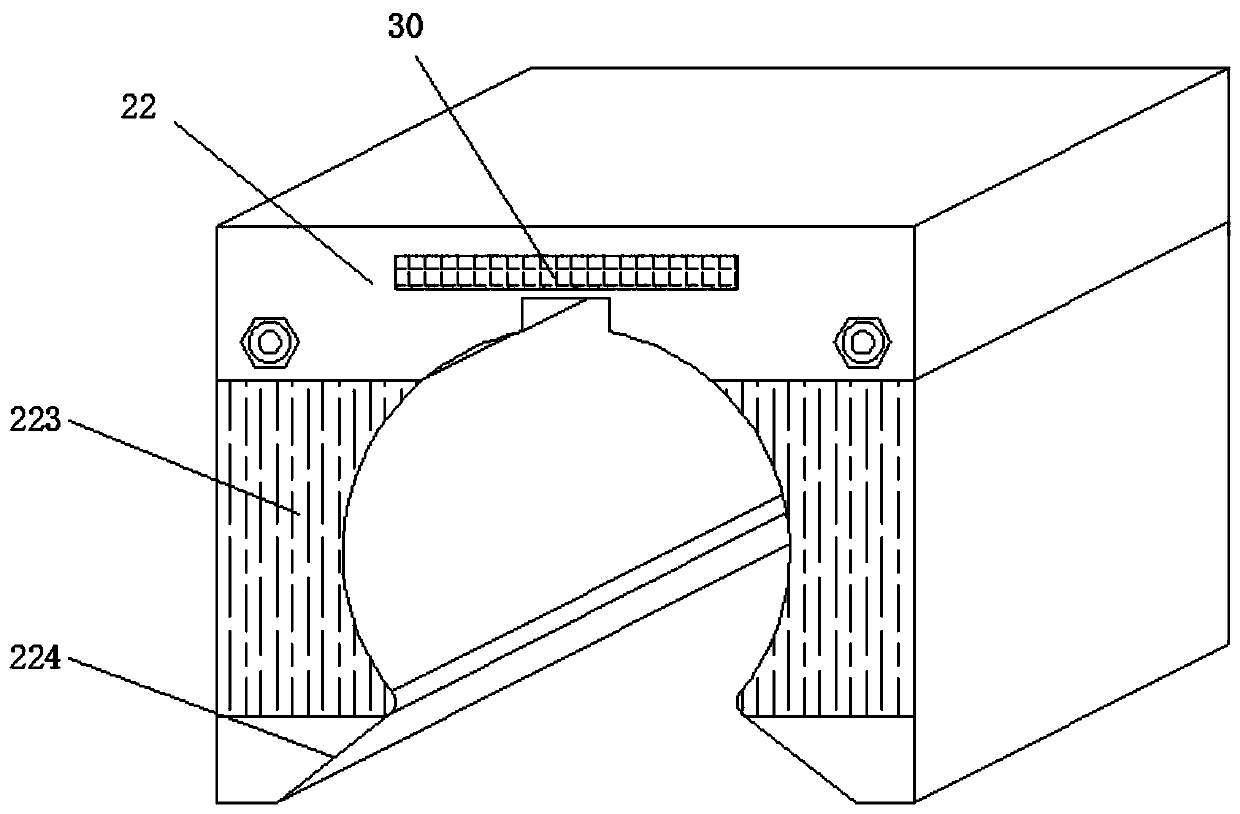

[0025] Such as figure 1 As shown, the pneumatic wheel pair pressing and positioning mechanism of a railway wheel pair rolling bearing running-in machine described in this embodiment includes a card wheel seat 10, a wheel pressing mechanism 20 and an infrared temperature measuring probe 30, and the card wheel seat 10 is a right-angle type structure, the end of the horizontal bar of the card wheel seat 10 is provided with a pressure wheel mechanism 20, and the pressure wheel mechanism 20 is used to limit the position of the wheel pair;

[0026] The pressure wheel mechanism 20 as a whole resists the bearing on the wheel pair, so that the pressure wheel mechanism 20 and the limit seat 51 on the running-in machine workbench 50 clamp the bearing, so that the bearing will not vibrate during the running-in process, improve the running-in quality, and use The effect is better; the top of the right-angled card wheel seat 10 protrudes outwards, and the upper 20 of the pressing wheel mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com