High-wear-resistance PVDF composite board and preparation method thereof

A composite plate and composite plate technology, applied in chemical instruments and methods, metal rolling, synthetic resin layered products, etc., can solve problems such as noise, wear of PTFE plastic layer, obvious vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

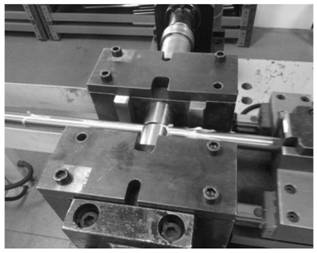

[0070] The present invention also provides a system for preparing a composite sheet, which can be used to prepare the PVDF composite sheet of the present invention, or other composite sheets having a metal substrate, an elastic layer (metal mesh layer) and a sliding layer (resin layer). The preparation system of the composite plate of the present invention can be used for extruding the resin composition onto the metal mesh surface of the heated metal mesh metal substrate composite plate, and then rolling to obtain the composite plate. The preparation system of the composite plate of the present invention includes a pulling device, a heating device, an extruder and a rolling mill, wherein the pulling device is used for pulling the metal mesh metal substrate composite plate to pass through the heating device and the rolling mill successively, and the heating device is used for the metal mesh metal substrate. The composite plate is heated, and the extruder is used to extrude the r...

Embodiment 1

[0084] The formula of the resin composition in this example is: 79wt% PVDF, 3wt% carbon fiber, 15wt% PTFE fine powder, 3wt% graphite powder.

[0085] The present embodiment adopts the following technology to prepare PVDF composite board:

[0086] (1) Lay the copper mesh on the passivated steel plate, the copper mesh is woven copper mesh, the wire diameter of the copper mesh is 0.25mm, and the mesh number of the copper mesh is 40 meshes, put it into a sintering furnace and sintered into a whole to obtain copper mesh. Mesh steel plate composite plate, wherein the sintering temperature is 900 ° C, the sintering time is 15 minutes, and the sintering process is protected by a hydrogen-nitrogen mixed atmosphere with a volume ratio of 3:1;

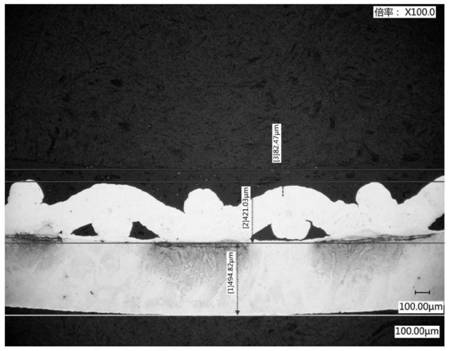

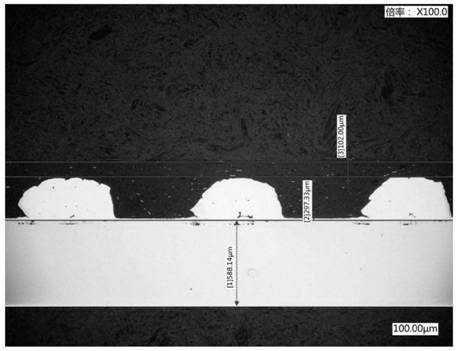

[0087] (2) mixing the components of the resin composition to obtain a mixture; putting the mixture into an extruder and directly extruding it onto the surface of the copper mesh of the steel strip copper mesh composite board that has been inducti...

Embodiment 2

[0089] The formula of the resin composition of this embodiment is: 80wt% PVDF, 5wt% carbon fiber, 10wt% PTFE fine powder, 5wt% graphite powder.

[0090] The present embodiment adopts the following technology to prepare PVDF composite board:

[0091] (1) Lay the copper mesh on the passivated steel plate, the copper mesh is woven copper mesh, the wire diameter of the copper mesh is 0.25mm, and the mesh number of the copper mesh is 40 meshes, put it into a sintering furnace and sintered into a whole to obtain copper mesh. Mesh steel plate composite plate, wherein the sintering temperature is 900 ° C, the sintering time is 15 minutes, and the sintering process is protected by a hydrogen-nitrogen mixed atmosphere with a volume ratio of 3:1;

[0092] (2) mixing the components of the resin composition to obtain a mixture; putting the mixture into an extruder and directly extruding it onto the surface of the copper mesh of the steel strip copper mesh composite board that has been indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com