Spherical bearing of single cylinder hydraulic cone crusher and manufacturing method

A technology of cone crusher and spherical bearing, which is applied in the fields of mining machinery manufacturing and hydraulic cone crusher manufacturing, can solve the problems of high manufacturing cost of copper alloys and high processing precision requirements, and achieves reduced manufacturing costs, good running-in properties, and increased contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

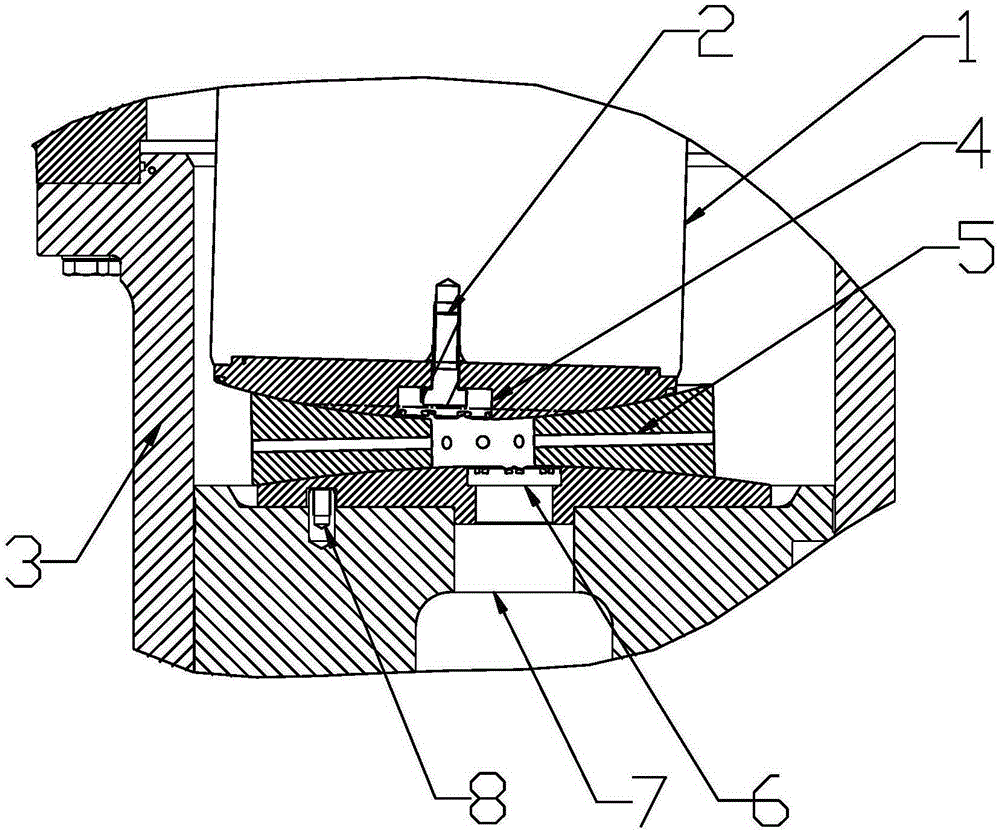

[0031] like Figure 1-4 As shown, a spherical bearing for a single-cylinder hydraulic cone crusher includes an upper part 4 of the spherical bearing, a middle part 5 of the spherical bearing and a lower part 6 of the spherical bearing.

[0032] The spherical bearing upper part 4 is the polyamide plastic spherical bearing upper part, the spherical bearing lower part 6 is the polyamide plastic spherical bearing lower part, and the spherical bearing middle part 5 is the alloy structural steel spherical bearing middle part after quenching and tempering.

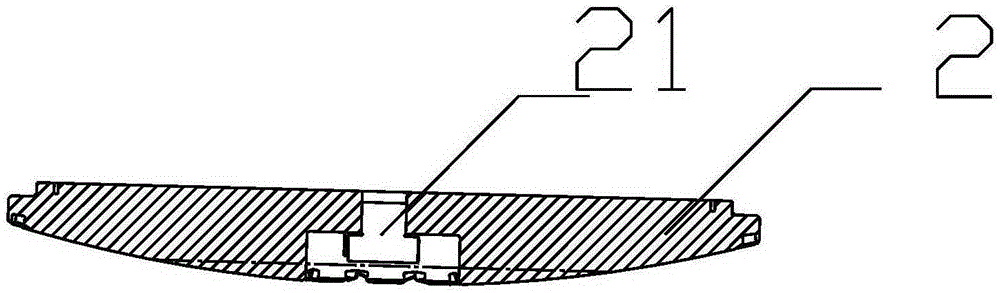

[0033] The upper part 4 of the spherical bearing is a lower semi-convex spherical shape, and a high-strength bolt mounting hole 21 is provided at the middle part.

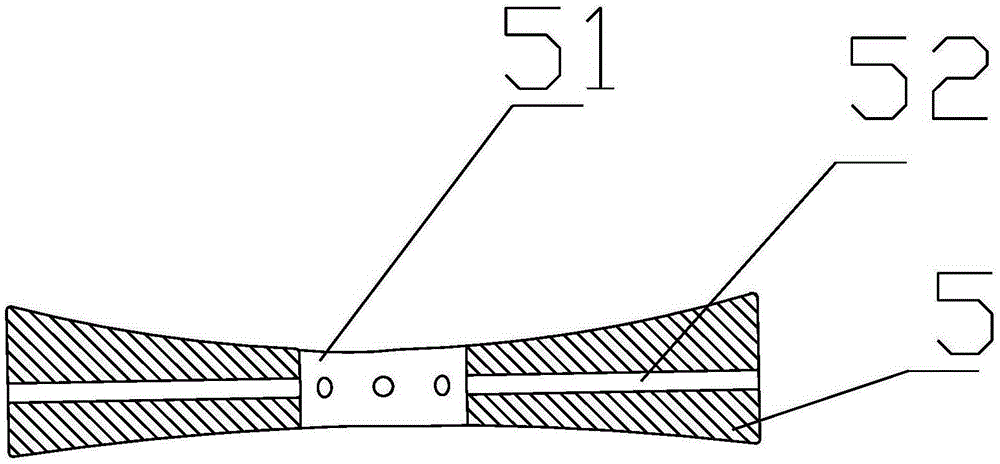

[0034] The middle part 5 of the spherical bearing is a symmetrical upper and lower concave spherical shape, and the middle part 5 of the spherical bearing is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com