DC motor and rubber cover assembly thereof

A technology of DC motor and plastic cover, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of poor reliability, waste of labor cost, complicated production process, etc., achieve stable and reliable conductive connection, simplify assembly process, The effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

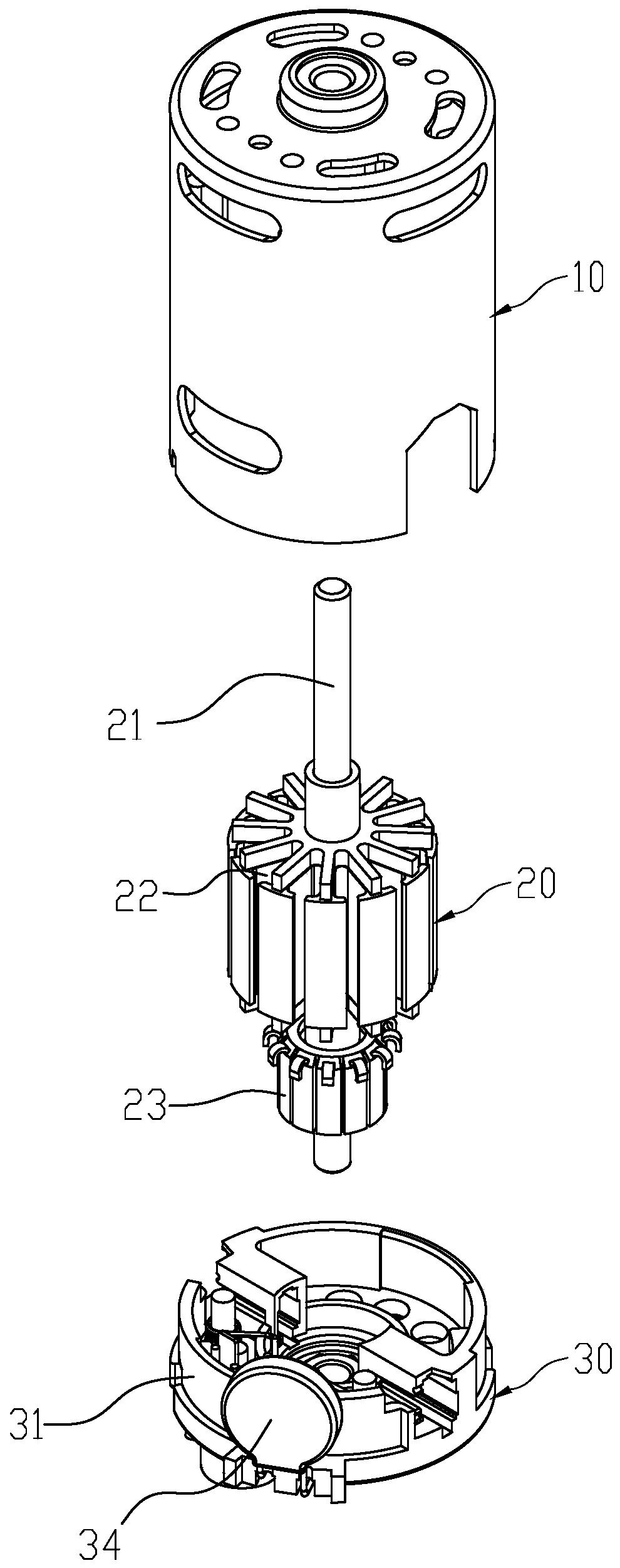

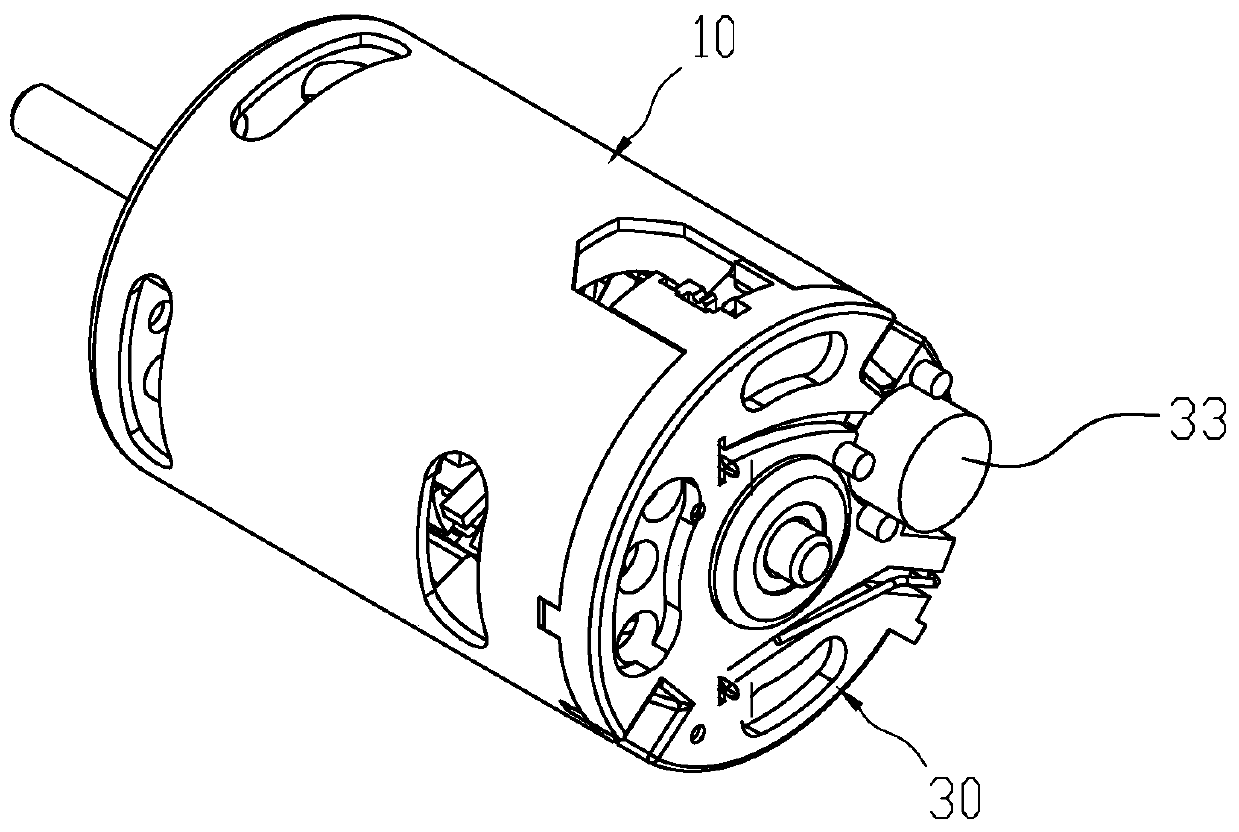

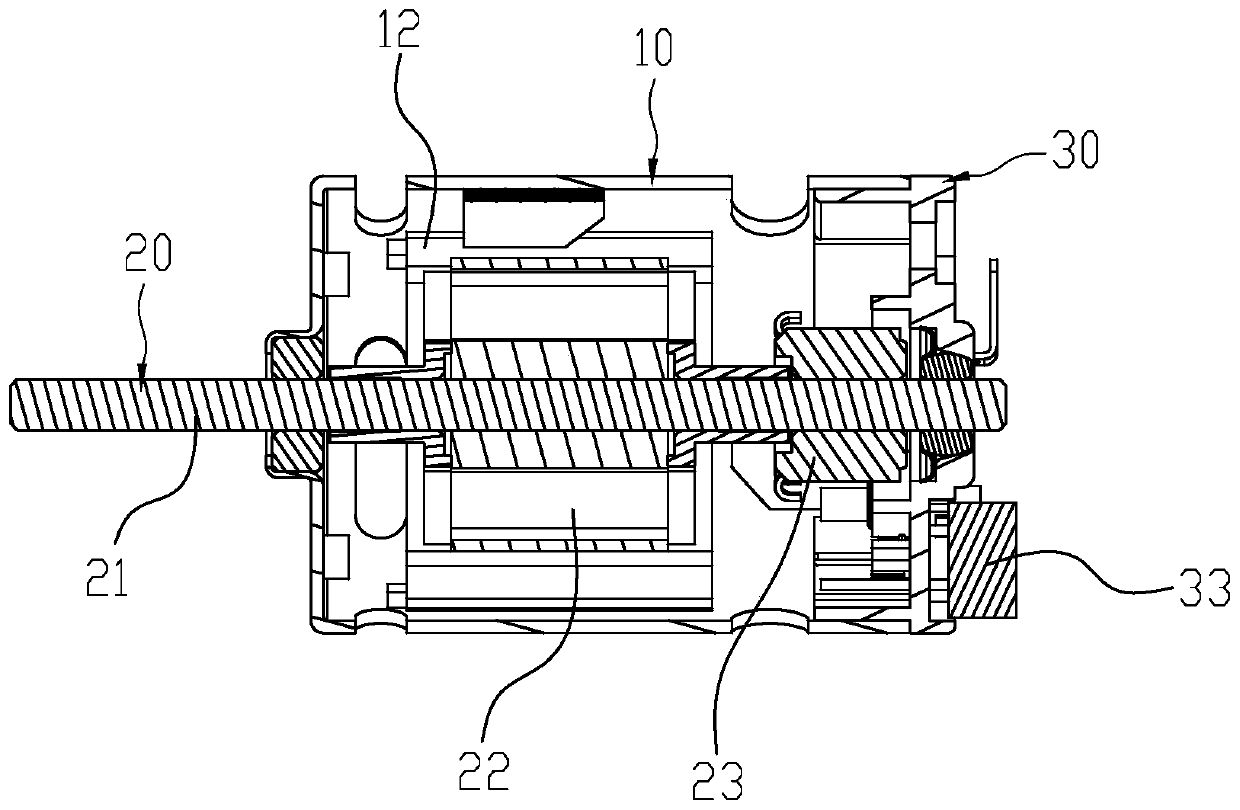

[0034] Please refer to Figure 1 to Figure 4 , a DC motor, including a stator 10, a rotor 20 and a rubber cover assembly 30. The stator 10 includes a housing 11 and a magnetic shoe 12 , one side of the housing 11 is open, and the magnetic shoe 12 is arranged in the housing 11 . The rotor 20 includes a shaft 21 , a coil 22 and a commutator 23 arranged on the shaft. The rotor 20 is rotatably arranged in the casing 11, the magnetic tile 12 just surrounds the outer side of the coil 22, and one end of the rotating shaft 12 protrudes from the end face on the other side of the casing 11, and the rubber cover assembly 30 covers the The open end surface of the housing 11 supports the other end of the rotating shaft 21 . The commutator 23 just corresponds to the inner cavity of the rubber cover assembly 30 , and the carbon brushes are arranged on the rubber cover assembly 30 and are in sliding contact with the commutator 23 . The operating circuit principle of the motor is existing k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com