Electric discharge machining jig and method

A technology of electrical discharge machining and fixtures, which is applied in the field of mold processing, can solve problems such as unsynchronized tightening of screws, abnormal mold quality, and tilting of copper males, etc., to save time for calibration, ensure processing quality, and avoid processing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

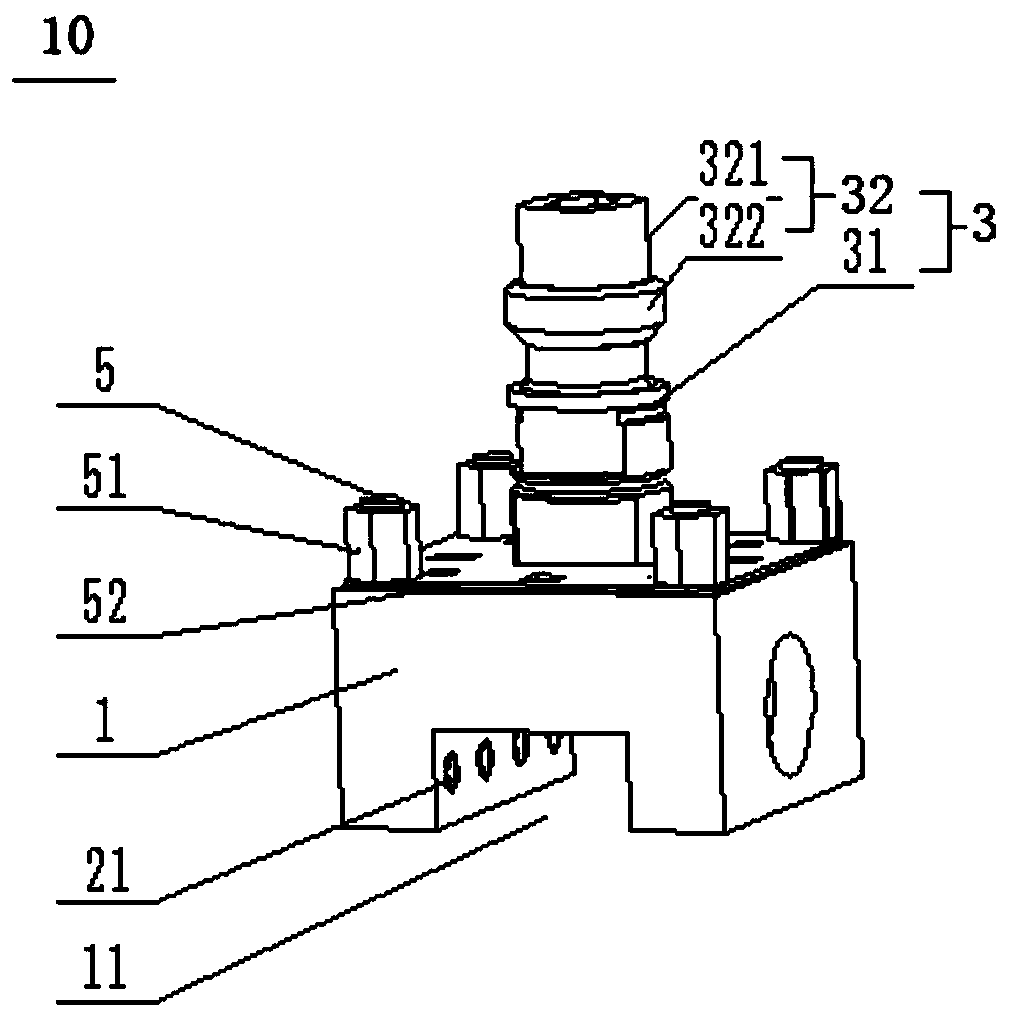

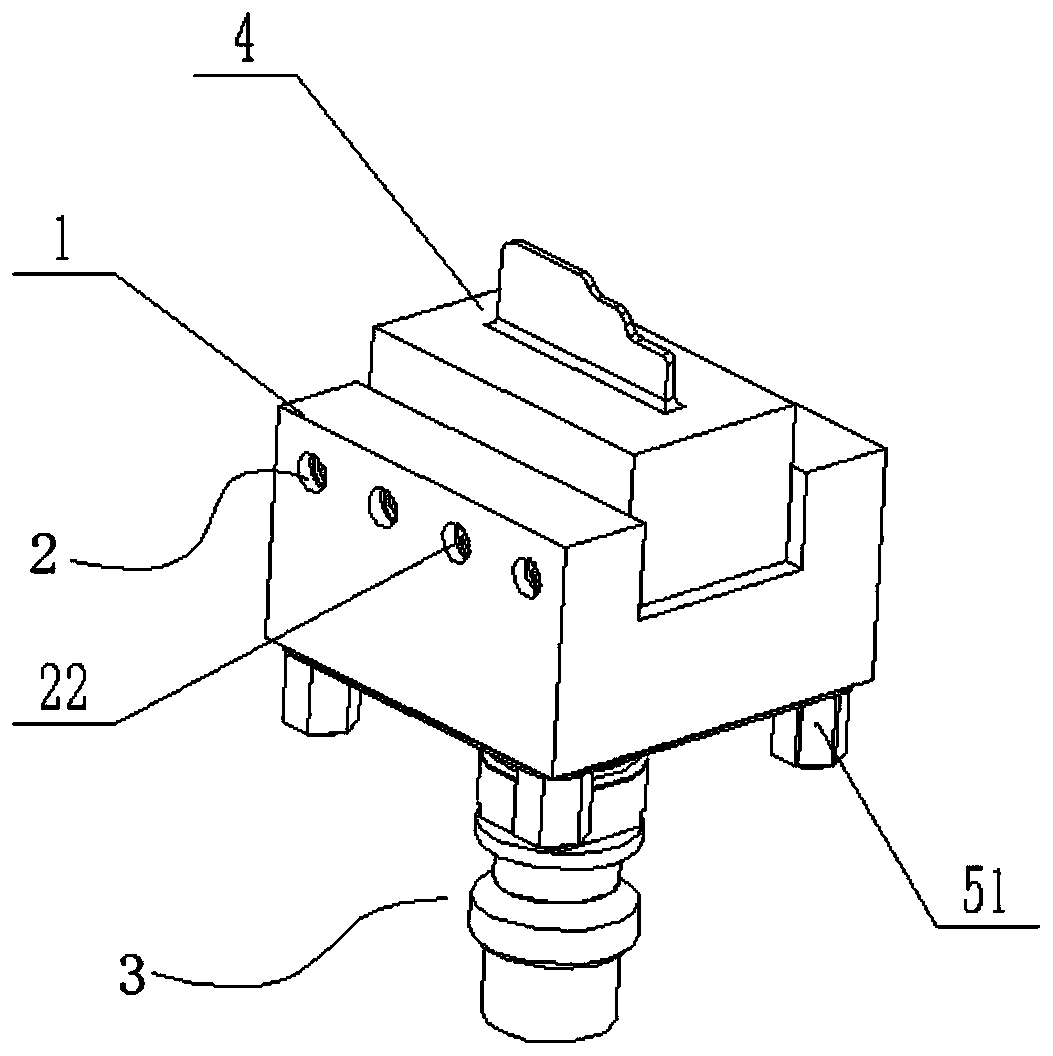

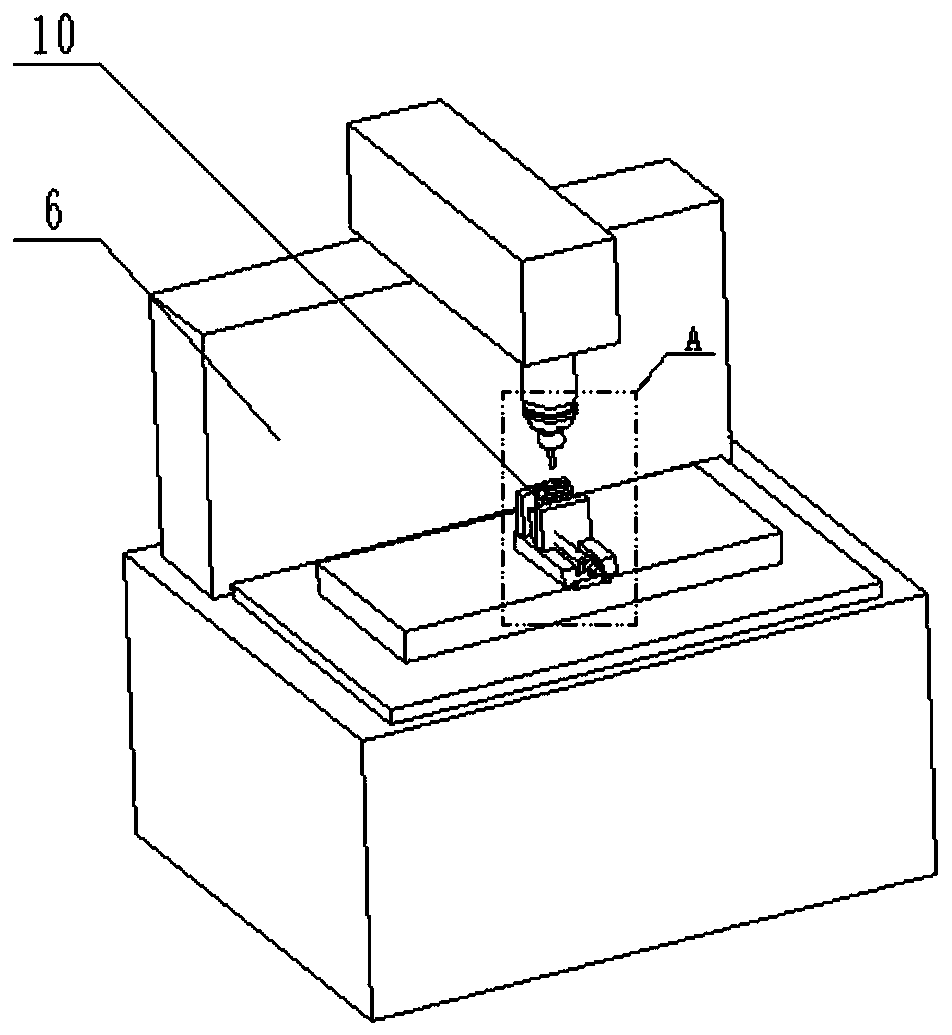

[0037] figure 1 shows a schematic structural view of an electrical discharge machining fixture according to the present application, figure 2 shown figure 1 Schematic diagram of the structure of the electric discharge machining fixture after the electrode is installed.

[0038] refer to figure 1 and figure 2 , the electrical discharge machining fixture 10 includes a fixture main body 1 , a positioning component 2 and a fixing component 3 .

[0039] The top of the fixture main body 1 has a groove 11 for accommodating the electrode 4, and the electrode 4 may be a graphite electrode or a copper male electrode. The positioning component 2 is arranged on the side wall of the fixture body 1 for fixing the electrode 4 . The fixing assembly 3 includes a fixing handle 31 and a connecting piece 32. The fixing handle 31 is arranged on the bottom surface of the fixture main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com