Double-layer board with turbulent flow column structure for cooling and vacuum electron beam machining method

A vacuum electron beam and electron beam processing technology, used in electron beam welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large deformation of the plate, low processing accuracy, complex process, etc., and achieve fast and efficient preparation and processing. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

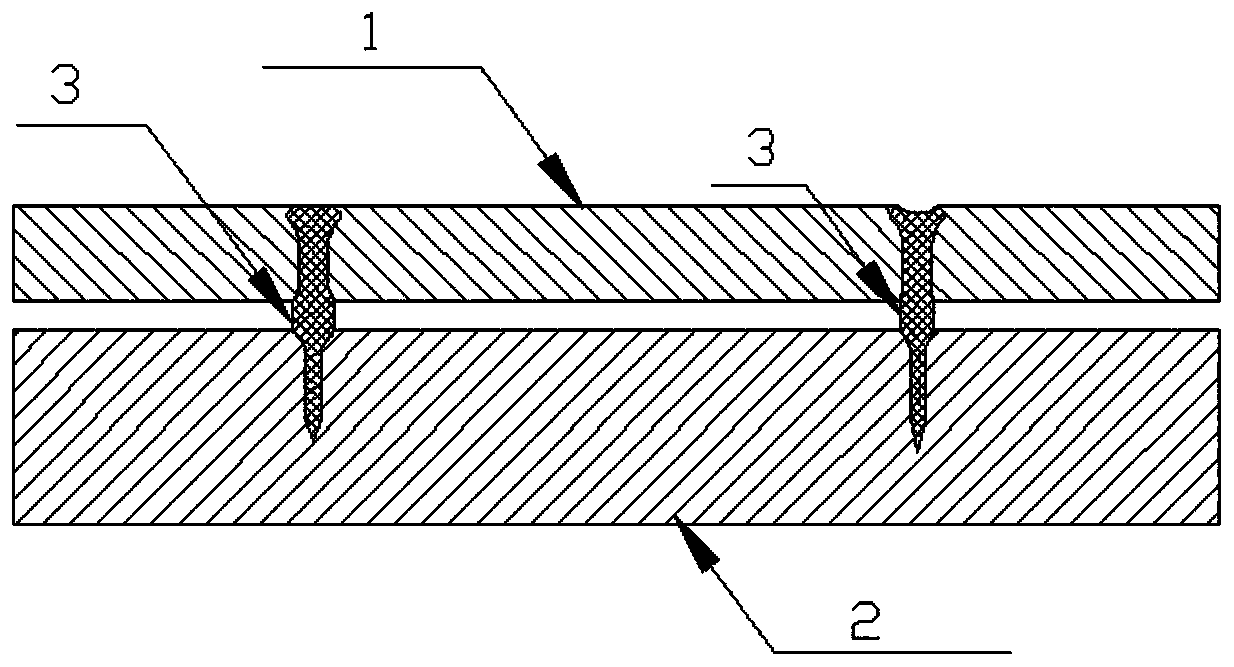

[0039] Such as Figure 1-4 As shown, this embodiment provides a double-layer panel with a spoiler column structure for cooling, including an upper panel and a lower panel, a gap is left between the upper panel and the lower panel, and a spoiler is arranged in the gap. In the stream column structure, the upper panel and the lower panel are connected together through the spoiler column structure.

[0040] In this implementation, the upper panel and the lower panel use metal plates; the thickness of the upper panel and the lower panel are the same or different, and the materials of the metal plates used in the upper panel and the lower panel are the same or different.

[0041] Wherein, the thickness of the upper panel and the lower panel is preferably 0.1 to 10 mm.

[0042] In this embodiment, the height of the spoiler structure is controlled by the height of the gap between the upper panel and the lower panel, which can be specified according to actual needs and manufacturing ...

Embodiment 2

[0053] Such as Figure 4-7As shown, this embodiment provides a double-layer panel with a spoiler column structure for cooling, including an upper panel and a lower panel, a gap is left between the upper panel and the lower panel, and a spoiler is arranged in the gap. In the stream column structure, the upper panel and the lower panel are connected together through the spoiler column structure.

[0054] In this implementation, the upper panel and the lower panel use metal plates; the thickness of the upper panel and the lower panel are the same or different, and the materials of the metal plates used in the upper panel and the lower panel are the same or different.

[0055] Wherein, the thickness of the upper panel and the lower panel is preferably 0.1 to 10 mm.

[0056] In this embodiment, the height of the spoiler structure is controlled by the height of the gap between the upper panel and the lower panel, which can be specified according to actual needs and manufacturing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com