Concrete mixing device for road construction

A technology of mixing device and road construction, applied in cement mixing device, clay preparation device, mixing operation control device, etc., can solve the problems of reducing construction quality, low efficiency, unable to achieve uniform and stable ingredients, etc., and improve construction efficiency , to avoid the effect of unnecessary waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

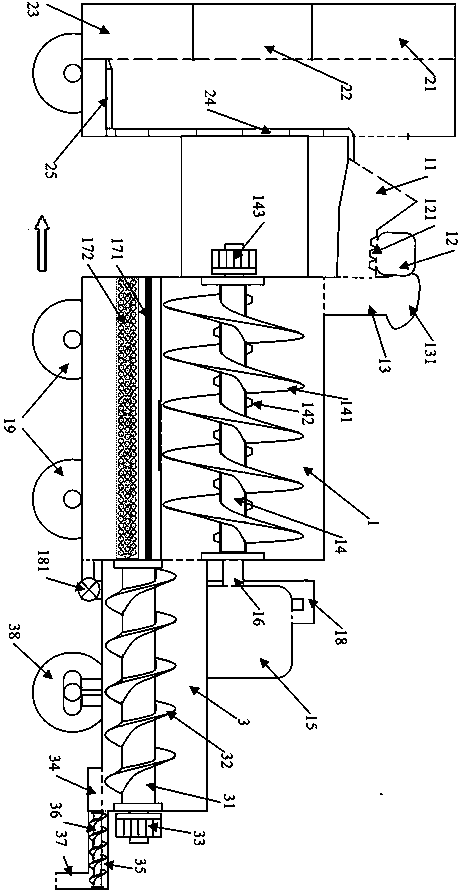

[0031] Further explanation in conjunction with accompanying drawings: as figure 1 The shown concrete mixing device for road construction includes a primary mixing component, a secondary mixing component and a feeding component.

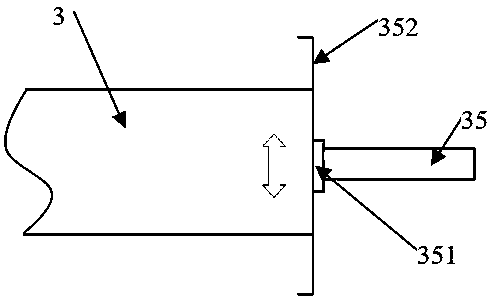

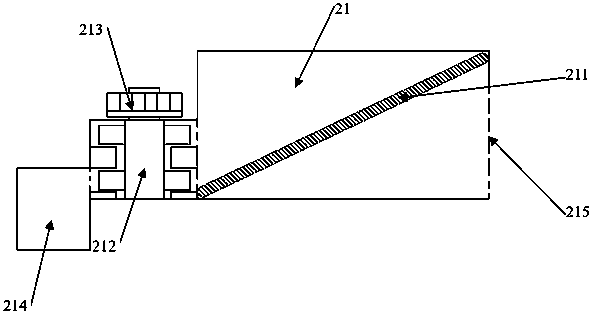

[0032] like figure 1 The primary stirring part shown includes a feeding part, a primary stirring chamber, a water circulation part and a walking wheel of a primary stirring chamber; the feeding part includes a mixture inlet pipe, a primary water storage chamber, a primary water nozzle, a primary Stirring chamber feeding pipe and ash retaining bag, the primary stirring chamber includes a primary stirring chamber inlet, a primary stirring shaft, a primary stirring blade, a stirring water nozzle, a primary stirring shaft drive motor, a stirring shaft inlet The water outlet, the discharge port of the primary mixing chamber and the water outlet of the primary stirring chamber; the water circulation component includes the shell of the water circulation com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com