A comprehensive anti-warping finishing device based on impregnated paper production

A sorting device and anti-warping technology, which is applied in the field of anti-warping comprehensive finishing device, can solve the problems that the edge of impregnated paper cannot be close to the tray, the edge gap, and the edge of impregnated paper is upturned, etc., so as to achieve easy finishing, ensure sealing, collection of handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

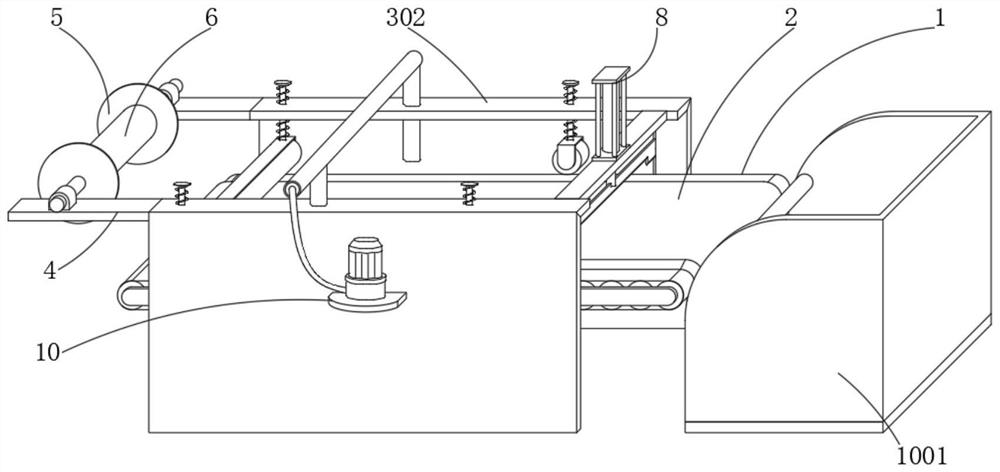

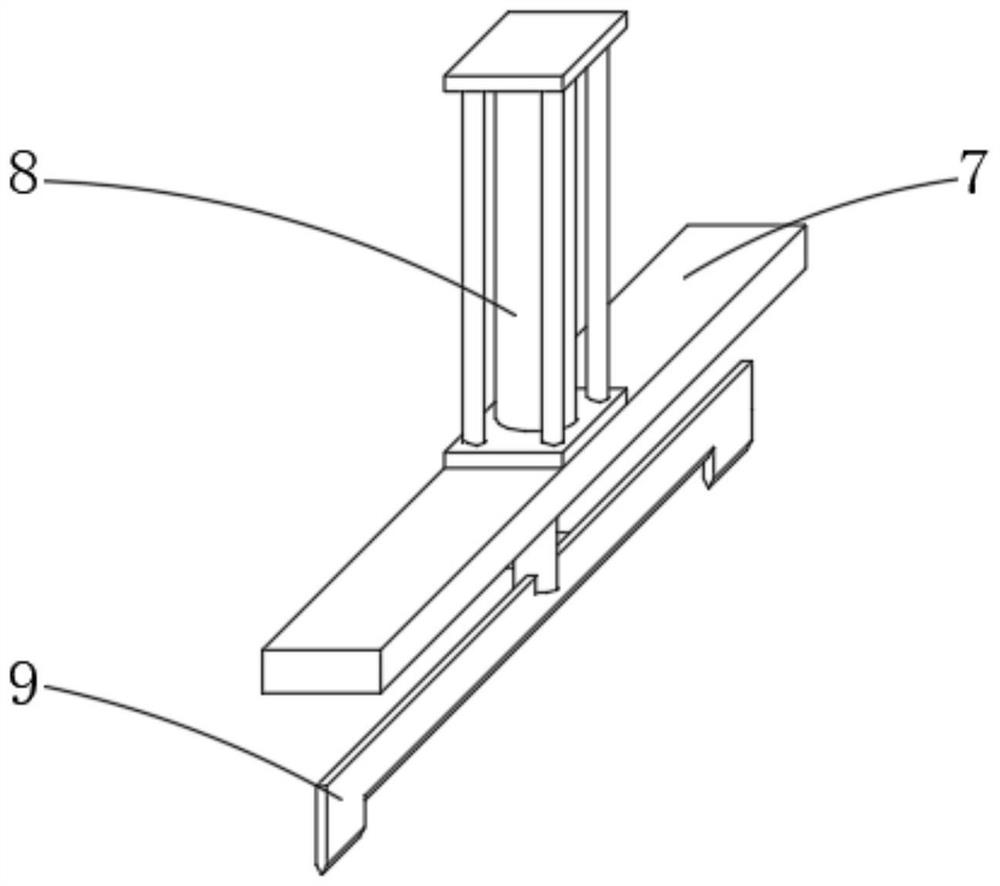

[0030] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, an anti-warping comprehensive finishing device based on impregnated paper production, including a conveyor belt 1, and a rubber gasket 2 is bonded to the middle of the conveyor belt 1;

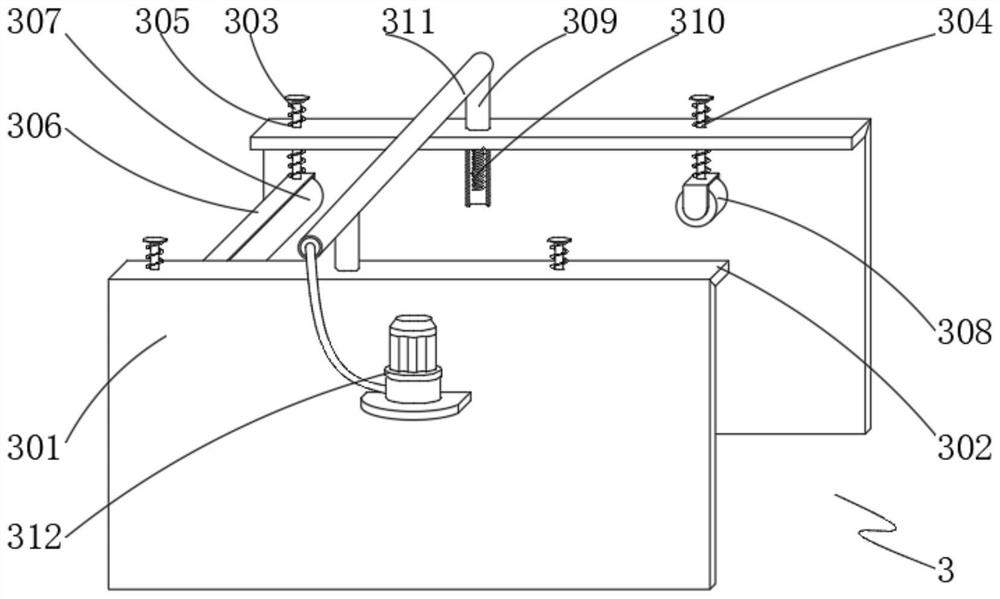

[0031] An anti-warping component 3 is installed on the outside of the conveyor belt 1, and the anti-warping component 3 includes a side plate 301, a mounting plate 302, a first movable rod 303, a second movable rod 304, a spring 305, a support frame 306, a guide roller 307, an extrusion Wheel 308, heating pipe 309, resistance wire 310, air supply pipe 311 and air pump 312;

[0032] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com