Movable small hoisting machine for municipal projects

一种吊装机、工程的技术,应用在传动装置、起重机、机械设备等方向,能够解决液压伸缩杆成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

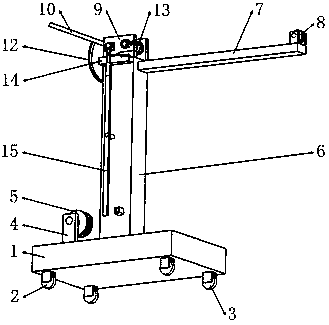

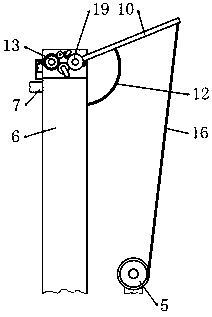

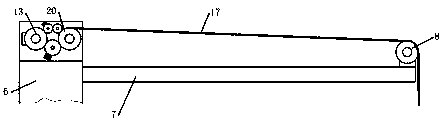

[0077] Such as Figure 5 As shown, it includes the first winding wheel 5, heavy base 1, such as figure 1 , 5 As shown, the first support plate 4 installed on the upper surface of the heavy base 1, the vertical support 6 installed on the upper surface of the heavy base 1, such as Figure 6 As shown, the two first fixed plates 9 and the horizontal bracket 7 that are symmetrically installed on the vertical support 6 at one end away from the heavy base 1, such as figure 1 Shown, the fixed pulley 8, the first wire rope 16, the second wire rope 17 fixedly installed on the upper surface of one end of the cross support 7, such as Figure 10 As shown, the first slider 26, the first rotating shaft 24, the driving wheel 19, the first rotating shaft 24, the driving wheel 19, such as two first guide blocks 27 are installed symmetrically. Figure 7 As shown, the pendulum plate 10, the leaf spring 12, the second rotating shaft 25, the second winding wheel 20, the rocking bar 21, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com