Anaerobic membrane bioreactor and application thereof in sewage treatment

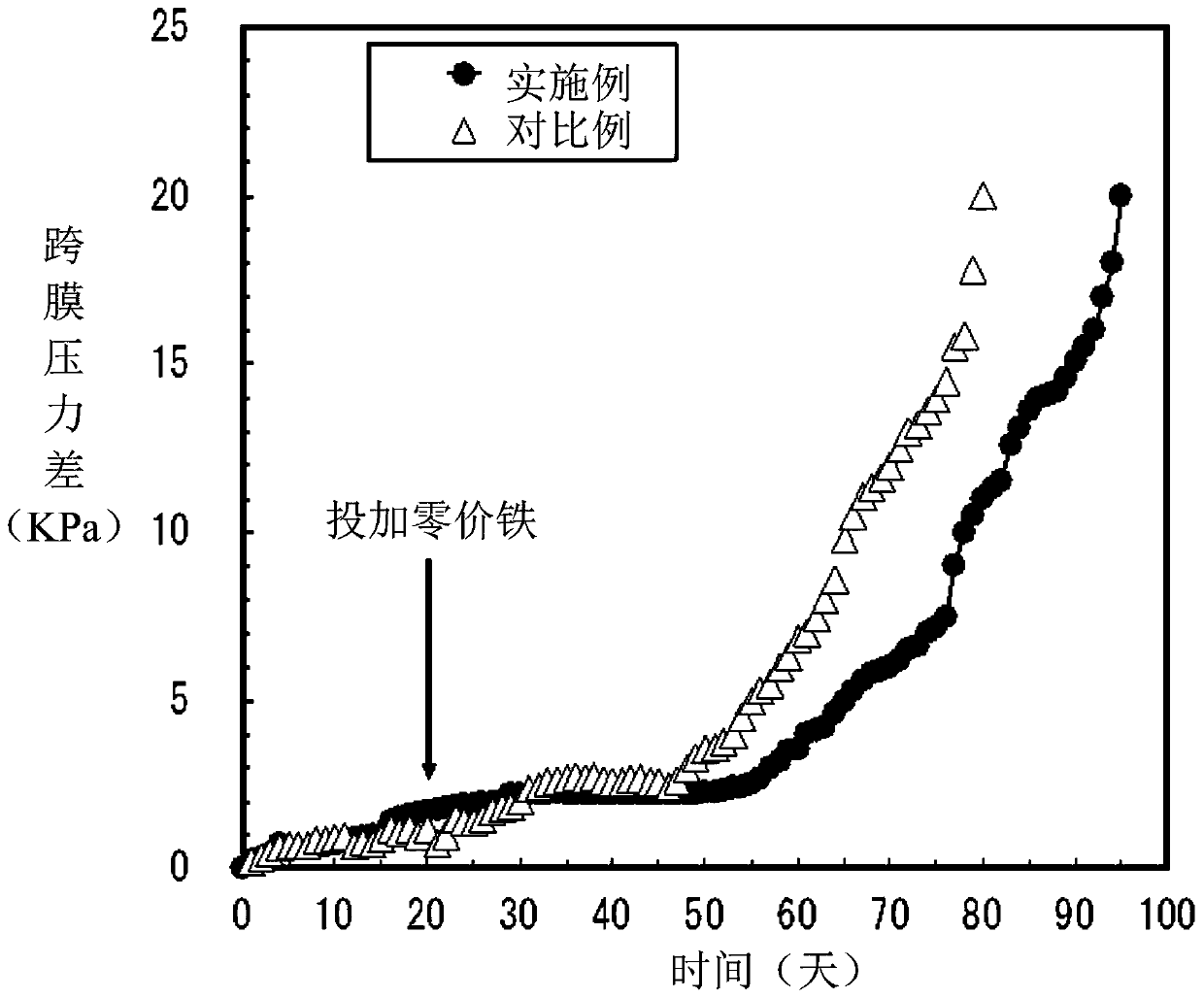

A technology for anaerobic membrane biology and sewage treatment, which is applied in biological water/sewage treatment, anaerobic digestion treatment, biological treatment equipment, etc. It can solve the problems that the type and amount of flocculant are not easy to control, and sulfur-containing sewage is difficult to treat. , to achieve the effect of prolonging the cycle of membrane fouling, slowing down the occurrence speed, and promoting the growth of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

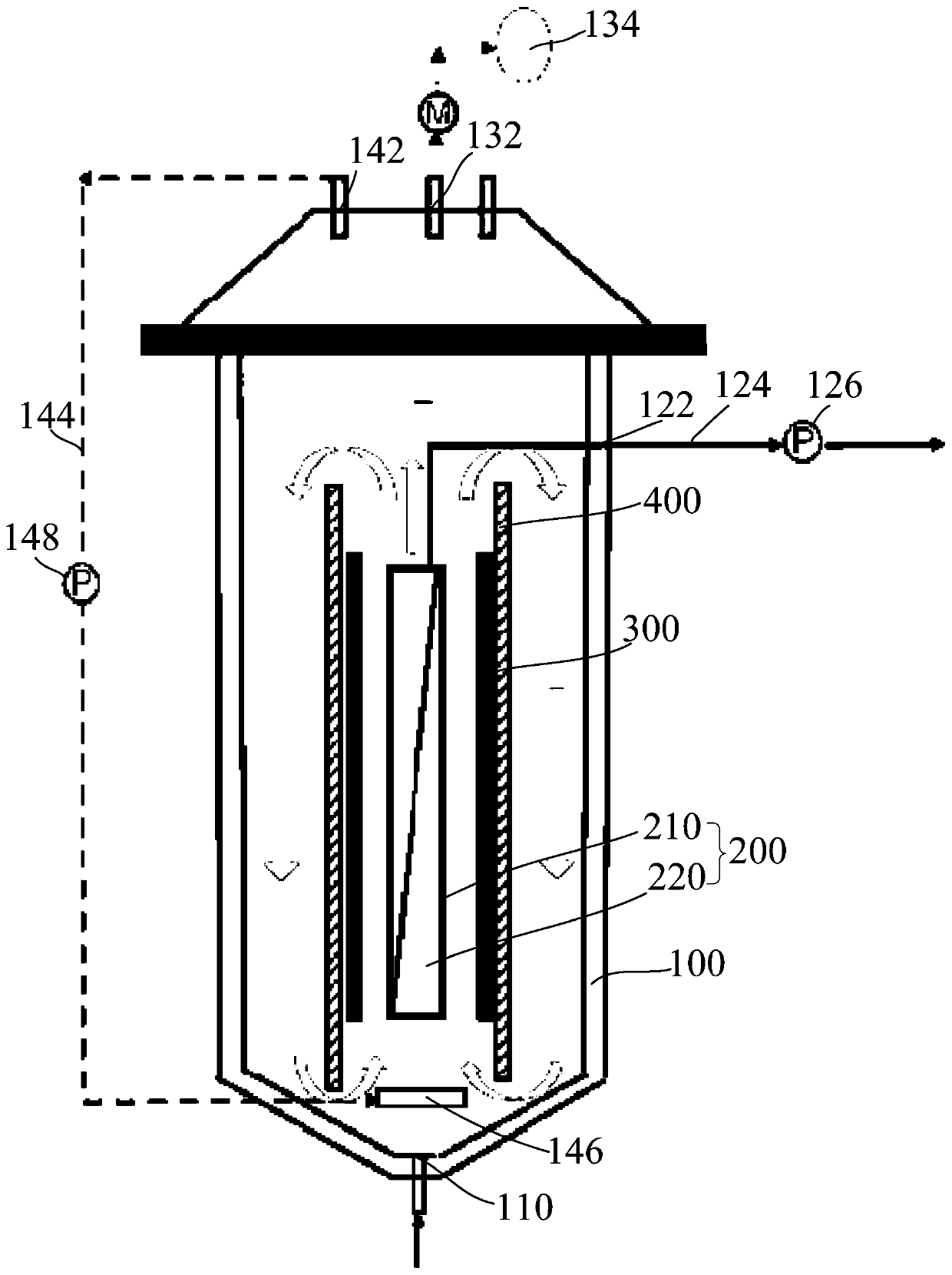

[0058] (1) Prepare two zero-valent iron plates with a length of 90 cm, a width of 5 cm, and a thickness of 0.3 cm. First soak in 0.1% NaOH, then pickle with 5% hydrochloric acid, then rinse with water to remove surface oil, rust and other impurities, and dry it for later use.

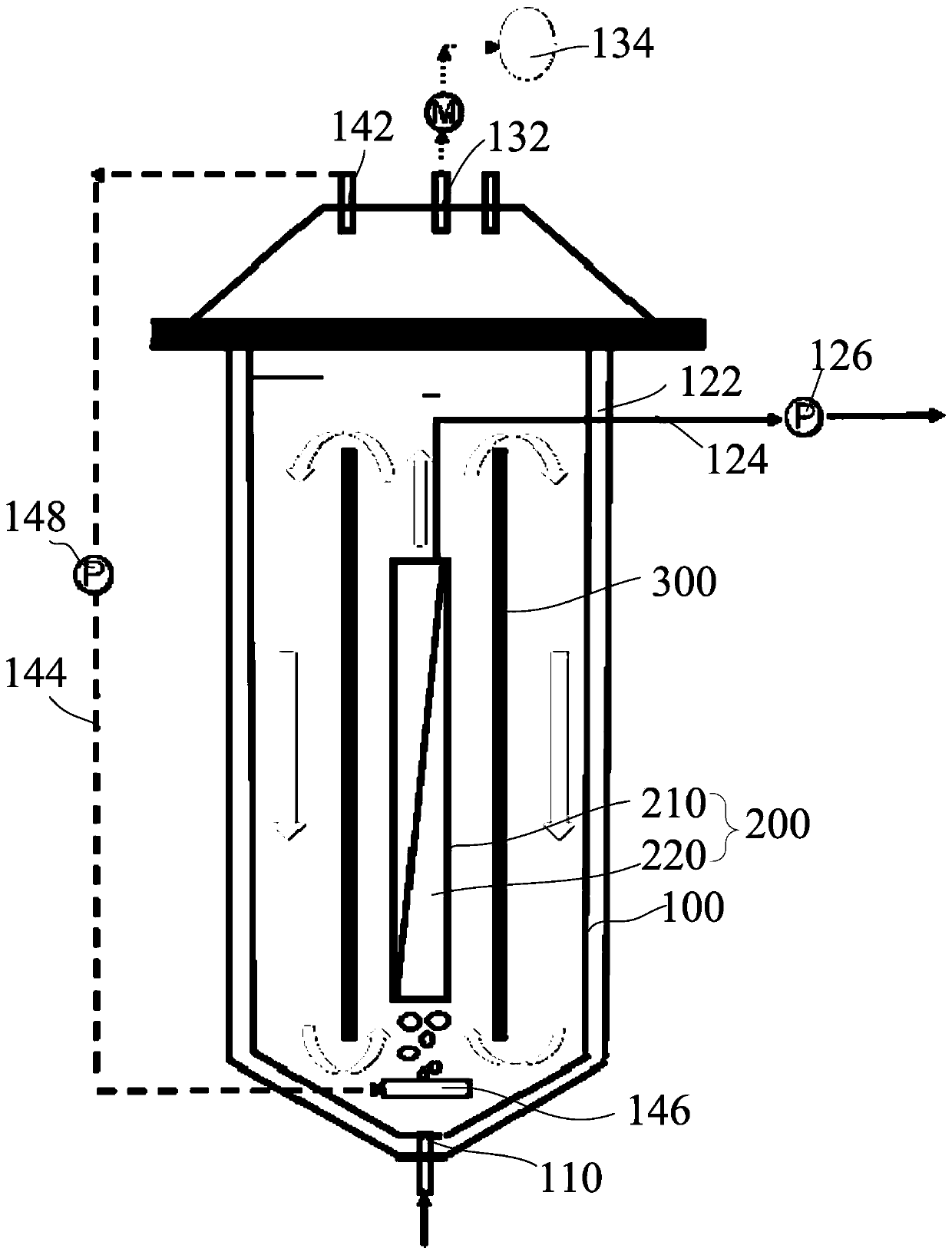

[0059] (2) Prepare anaerobic membrane bioreactor device. The reactor uses flat membrane modules, the membrane material is polyvinylidene fluoride, and the membrane pore size is 0.1 μm.

[0060] (3) First, do not install zero-valent iron plates in the anaerobic membrane bioreactor, inoculate anaerobic sludge in the anaerobic membrane bioreactor device, and conduct domestication. Simulated domestic sewage is used in the domestication process, the hydraulic retention time is 10h, the temperature of the reactor is controlled to about 35℃ with an insulation belt, the constant flux mode is adopted in the operation process, and the flux is 15L / (m 2 / h). During the domestication process, the indicators of gas prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com