Admixture for concrete repairing and preparation method thereof

An admixture and concrete technology, which is applied in the field of soil remediation, can solve the problems of prone to cracks and low ultimate elongation in concrete, and achieve the effect of improving ultimate elongation, good effect and reducing the probability of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

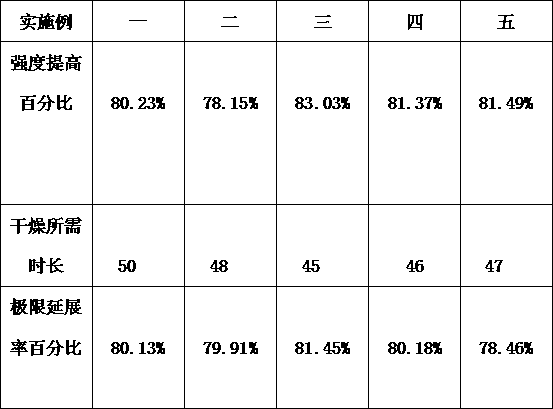

Examples

Embodiment 1

[0025] The present invention proposes an admixture formula for concrete restoration, comprising the following raw materials in parts by weight: 10 parts of ferrous sulfate, 11 parts of diatomite, 5 parts of bentonite, 12 parts of barium nitrate, 5 parts of carboxylic acid, and 22 parts of gypsum powder , 18 parts of sand aggregate, 5 parts of additive, 22 parts of steel fiber, 30 parts of deionized water, 3 parts of magnesium stearate;

[0026] Its preparation method comprises the following steps:

[0027] S1: Use weighing equipment to weigh ferrous sulfate, diatomite, bentonite, barium nitrate, carboxylic acid, gypsum powder, sand and gravel aggregate, additives, steel fiber, deionized water, and magnesium stearate according to the proportion ;

[0028] S2: Put the weighed barium nitrate, diatomaceous earth, bentonite and deionized water into the heating box for hot mixing, hot mixing for 500s, so that the temperature of the material reaches 100°C, and wait until the mixture...

Embodiment 2

[0033] The present invention proposes an admixture formula for concrete restoration, comprising the following raw materials in parts by weight: 11 parts of ferrous sulfate, 12 parts of diatomite, 6 parts of bentonite, 13 parts of barium nitrate, 6 parts of carboxylic acid, and 23 parts of gypsum powder , 19 parts of sand aggregate, 6 parts of additive, 23 parts of steel fiber, 31 parts of deionized water, 4 parts of magnesium stearate;

[0034] Its preparation method comprises the following steps:

[0035] S1: Use weighing equipment to weigh ferrous sulfate, diatomite, bentonite, barium nitrate, carboxylic acid, gypsum powder, sand and gravel aggregate, additives, steel fiber, deionized water, and magnesium stearate according to the proportion ;

[0036] S2: Put the weighed barium nitrate, diatomaceous earth, bentonite and deionized water into the heating box for hot mixing, hot mixing for 550s, so that the temperature of the material reaches 150°C, and wait until the mixture...

Embodiment 3

[0041] The present invention proposes an admixture formula for concrete restoration, comprising the following raw materials in parts by weight: 12 parts of ferrous sulfate, 13 parts of diatomite, 7 parts of bentonite, 14 parts of barium nitrate, 7 parts of carboxylic acid, and 24 parts of gypsum powder , 20 parts of sand aggregate, 7 parts of additive, 24 parts of steel fiber, 32 parts of deionized water, 5 parts of magnesium stearate;

[0042] Its preparation method comprises the following steps:

[0043] S1: Use weighing equipment to weigh ferrous sulfate, diatomite, bentonite, barium nitrate, carboxylic acid, gypsum powder, sand and gravel aggregate, additives, steel fiber, deionized water, and magnesium stearate according to the proportion ;

[0044] S2: Put the weighed barium nitrate, diatomaceous earth, bentonite and deionized water into the heating box for hot mixing, hot mixing for 560s, so that the temperature of the material reaches 110°C, and wait until the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com