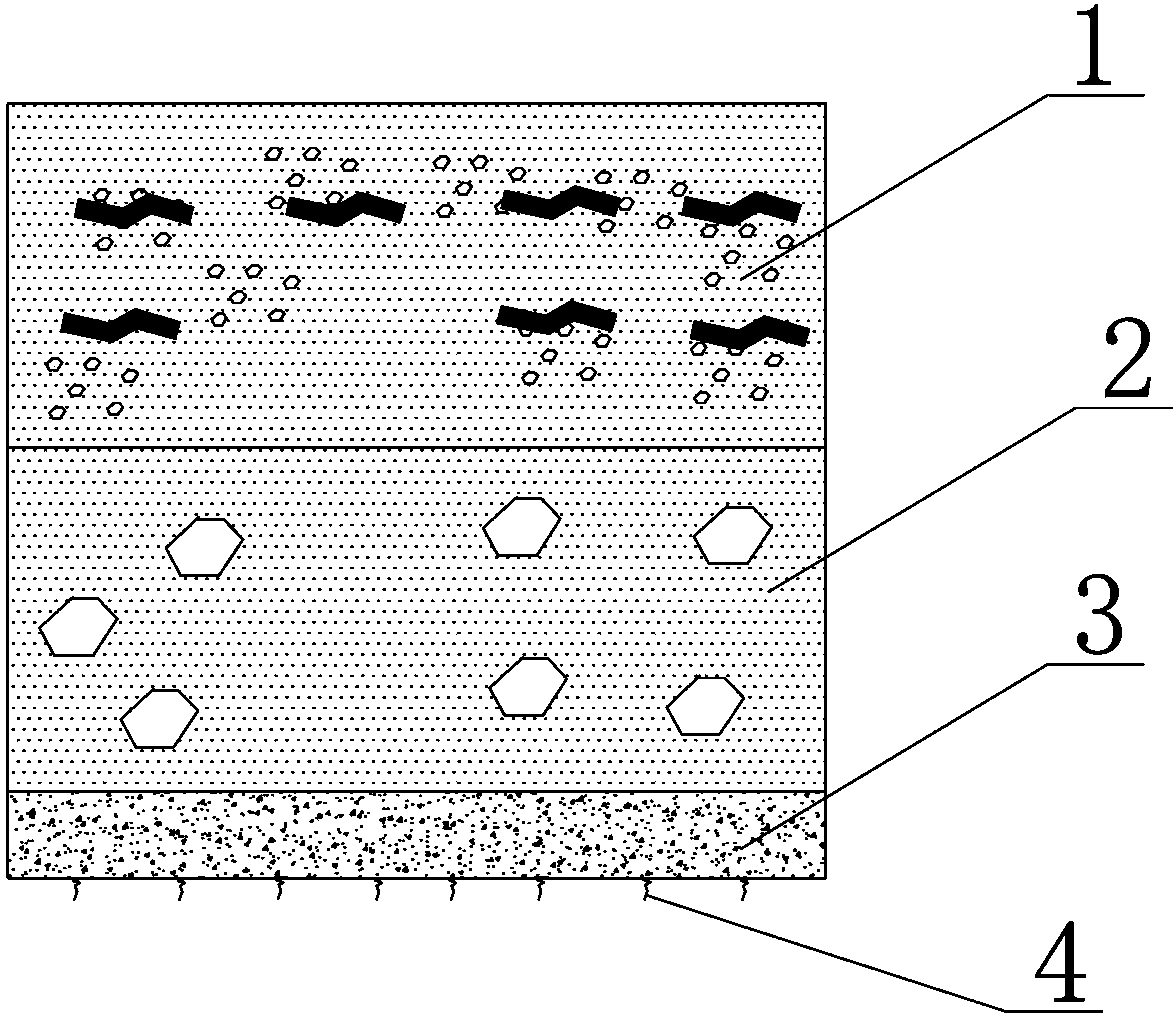

Polypropylene fiber concrete roadway structure suitable for large-tonnage cars and construction method

A technology of polypropylene fiber and concrete pavement, which is applied to coagulation pavement paved on site, roads, roads, etc., can solve the problems of not meeting driving requirements, difficulty in large-scale promotion, narrow use area, etc., and achieves good alkali resistance , the ultimate elongation rate is large, and the effect of improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0071] The used raw material of polypropylene fiber concrete surface course of the present invention has the weight proportion of the concrete of every cubic meter label C60 as:

[0072] Cement: 52.5# cement 380kg / m 3

[0073] Fly ash: 50kg / m 3

[0074] Slag fine powder: 50 kg / m 3

[0075] Water: 130 kg / m 3

[0076] Sand: 30 kg / m 3

[0077] Gravel: 1250 kg / m 3

[0078] Polycarboxylate high-performance water reducer 2.2 kg / m 3

[0079] Polypropylene fiber: 5.4kg / m 3 .

[0080] The present invention adopts the high-strength wear-resistant polypropylene fiber concrete pavement structure to replace the mud knot and graded crushed stone pavement, so as to achieve the purpose of improving the strength of the entire pavement structure. The adoption of the above-mentioned pavement structure can greatly improve the road surface of the existing large-tonnage vehicles in mines. Standards, so as to achieve the purpose of reducing transportation costs and reducing road mainte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com