Front-section fermentation device for preparation of animal waste organic fertilizer

A fermentation device and animal manure technology, which is applied in the field of animal manure organic fertilizer fermentation, can solve the problems of increased harmful gas emissions, unfavorable environmental protection requirements, and decreased fermentation efficiency, so as to increase the air flow rate, increase the effective contact area, and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

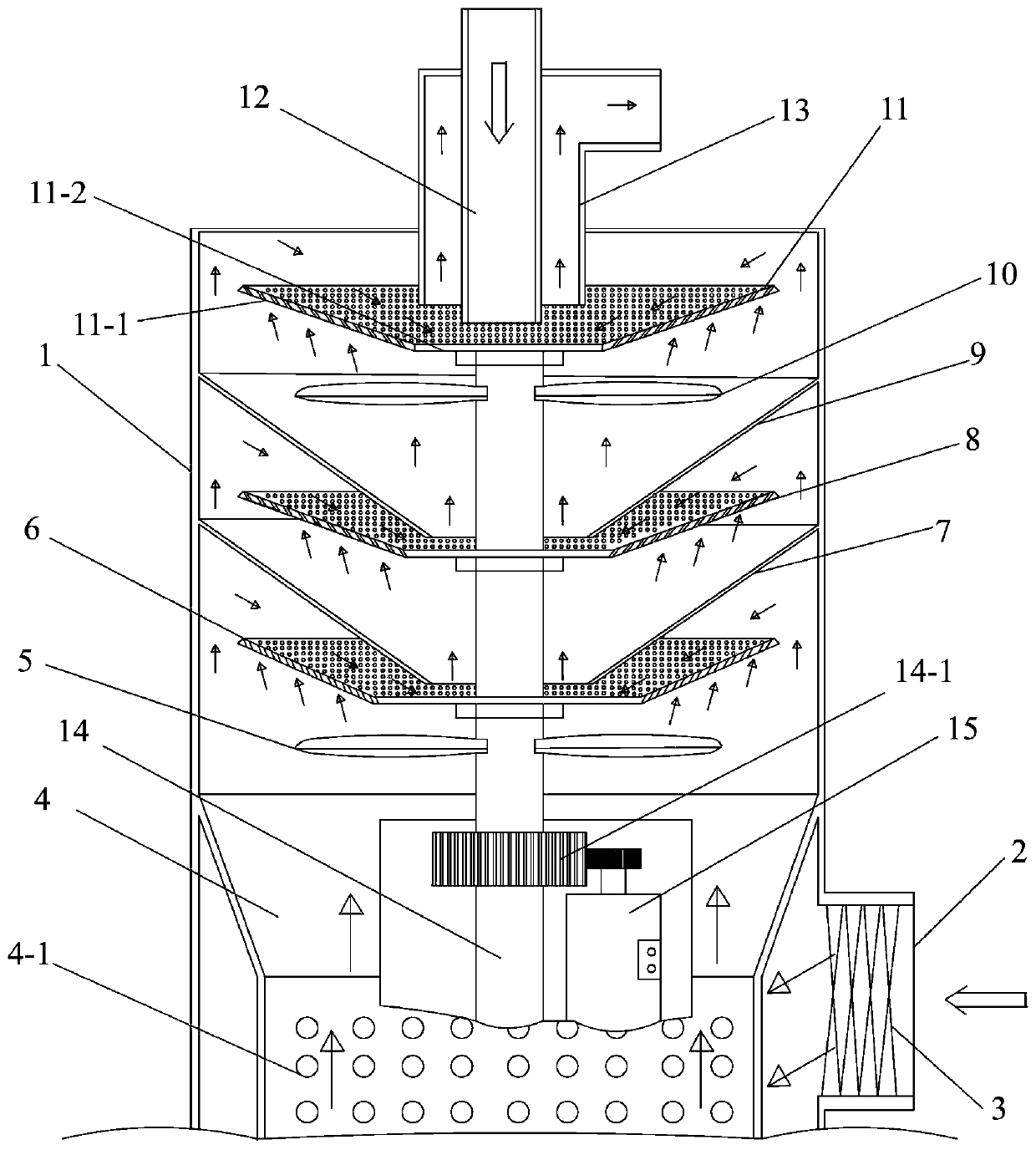

[0020] Such as figure 1 As shown, a front-stage fermentation device for animal manure organic fertilizer includes a device body 1, in which a first funnel-shaped centrifugal table 11, a second funnel-shaped centrifugal table 8, and a third funnel are distributed sequentially from top to bottom in the device body 1. Shape centrifugal table 6; Of course, the number of layers of funnel-shaped centrifugal table can be selected according to needs; The above-mentioned three funnel-shaped centrifugal tables all include a bottom plate 11-2 and a funnel side plate; the side plate of the funnel is provided with a number of ventilation pores 11-1, and the ventilation pores on the side plate of the funnel are from bottom to top, Opening inclined from the inside to the outside is mainly to prevent clogging caused by the centrifugation process and to promote the flow trend of the bottom-up air flow to the outer periphery. The inclination of the funnel side plate of the second funnel-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com