A kind of process control method of lysine acetate preparation process

A technology for the preparation of lysine acetate, which is applied in the field of process control of the preparation process of lysine acetate, can solve the problems of low concentration of lysine acetate decolorization and filtration, blockage of filter pipes, and influence on product quality, so as to avoid excessive Effects of collecting, reducing chromatic aberration, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

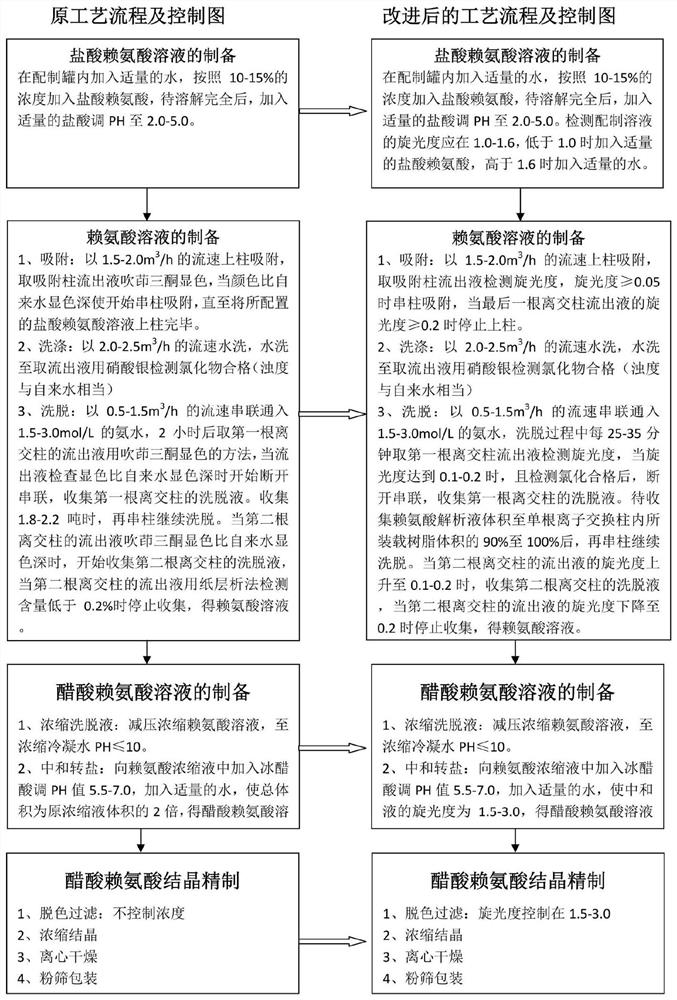

Method used

Image

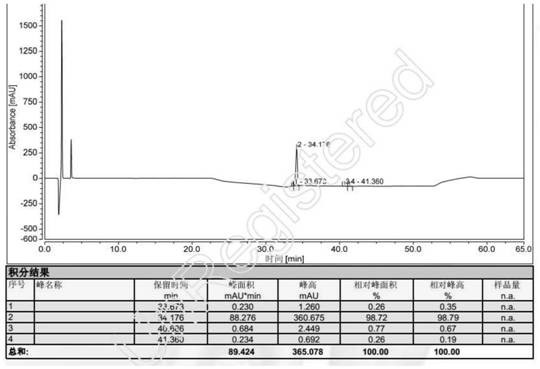

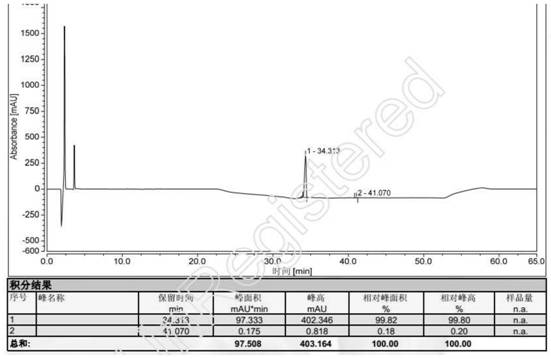

Examples

Embodiment 1

[0038] 1. Preparation of lysine hydrochloride solution: add an appropriate amount of purified water into the preparation tank, add lysine hydrochloride according to the concentration of 10-15%, then add an appropriate amount of concentrated hydrochloric acid, adjust the pH value to 2.0-5.0, and use optical rotation The optical rotation of the prepared solution is measured by the instrument, and the optical rotation is preferably controlled at 1.0 to 1.6.

[0039] The original process: the solution is prepared according to the theoretical calculation value, and the actual concentration of the solution is not detected. In this way, in large-scale production, it is often easy for the production equipment to be unable to accurately measure or the operator to operate the wrong operation to prepare the volume inaccurately, resulting in the concentration of the preparation solution being too low, resulting in waste of energy in the separation process and low single-batch yield; the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com