Pyridinesulfur dioxide and production technology thereof

A technology of sulfur dioxide and production process, applied in the direction of organic chemistry, etc., to achieve the effects of high product purity, high reaction speed and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

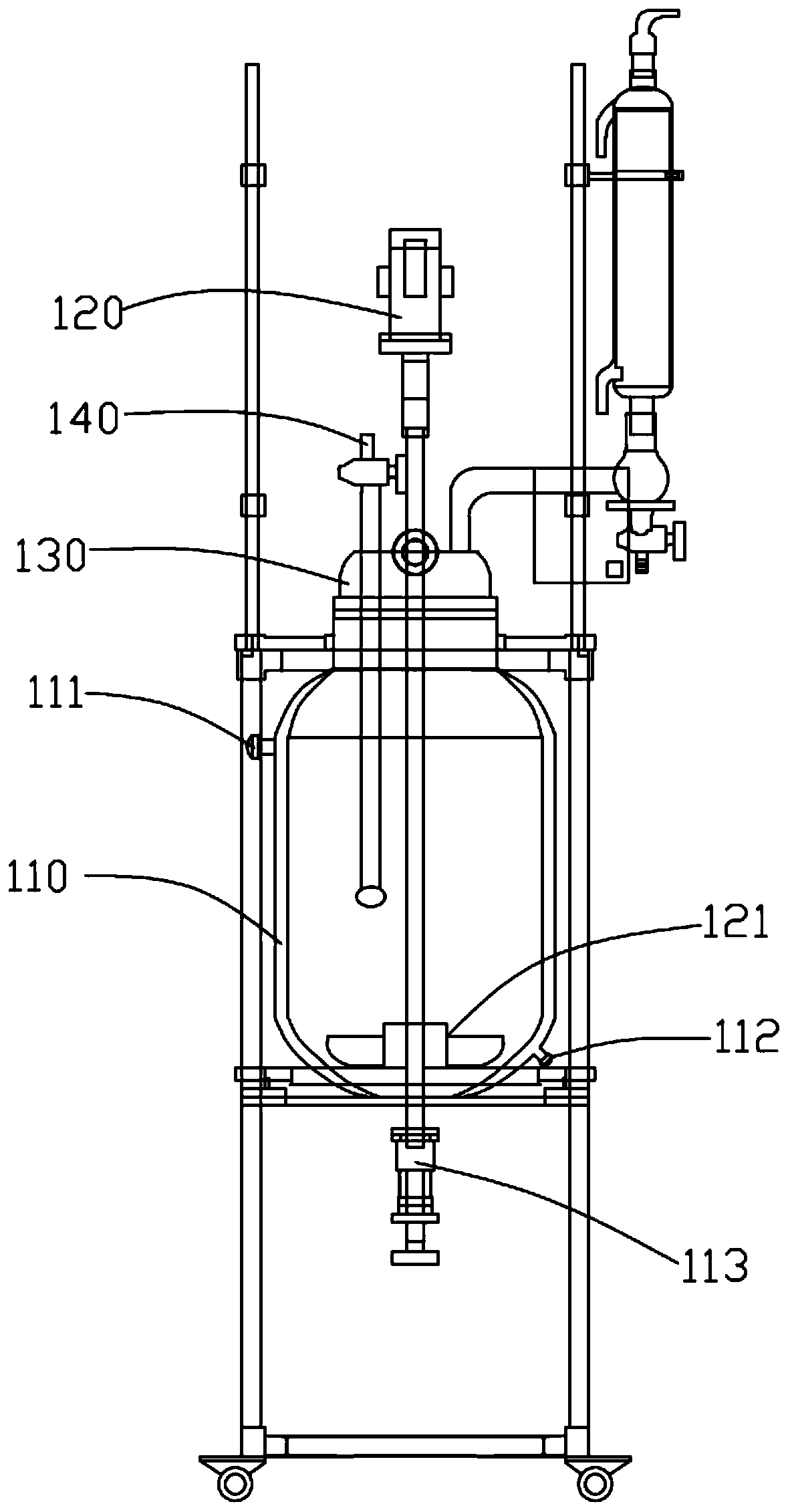

Image

Examples

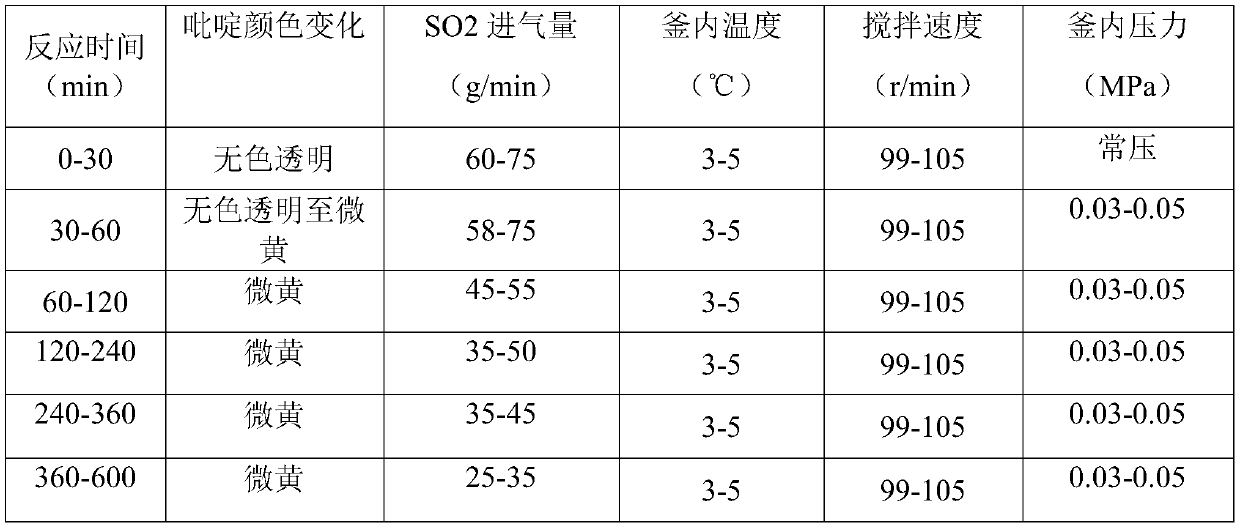

Embodiment 1

[0046] Prepare pyridine sulfur dioxide of the present invention, comprise the steps:

[0047] (1) Take 80 kg of pyridine with a high-precision electronic balance, filter and remove impurities with a 1 μm filter element, and put it into the reactor;

[0048] (2) To carry out the cooling treatment of the reaction device, the temperature in the control reactor is controlled to be 3-5°C;

[0049] (3) Accurately weigh sulfur dioxide and make it flow into the reaction kettle with an air flow of 75g / min, and start stirring simultaneously, the stirring speed is 95r / min, after reacting for 30min, adjust the internal pressure of the reaction device to be a negative pressure of 0.03-0.05MPa;

[0050] (4) Fully mix the reacted materials for 5 minutes, then filter at normal pressure, and fill to obtain pyridine sulfur dioxide. The temperature in the reaction kettle is 5-10° C. during filling.

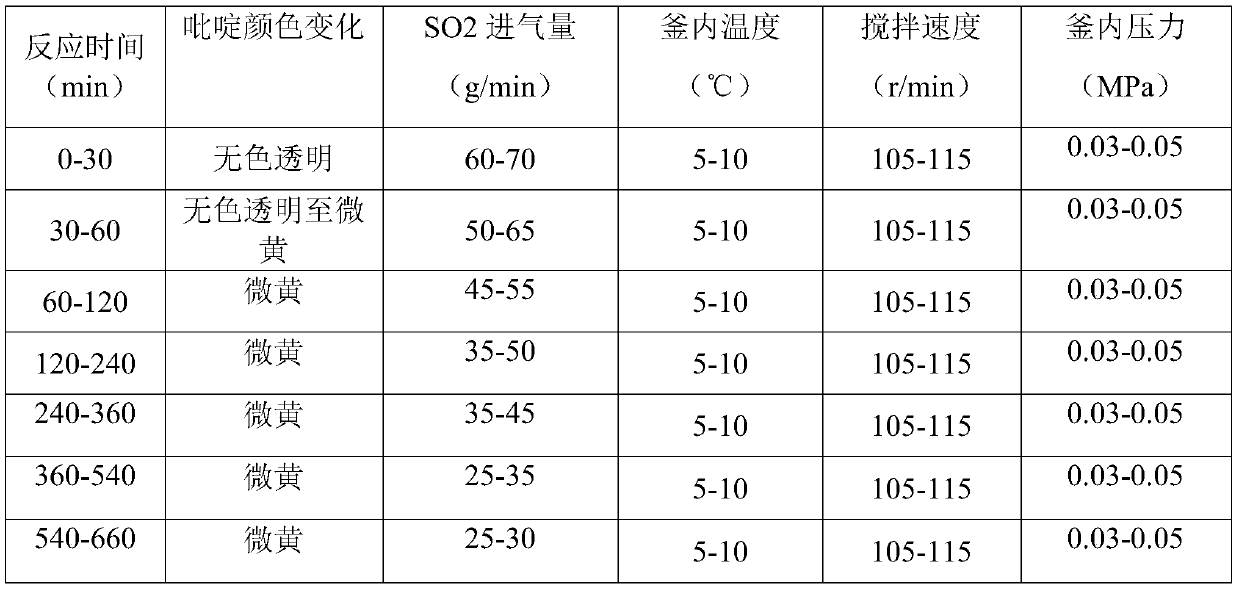

Embodiment 2

[0052] Prepare pyridine sulfur dioxide of the present invention, comprise the steps:

[0053] (1) Take 80 kg of pyridine with a high-precision electronic balance, filter and remove impurities with a 1 μm filter element, and put it into the reactor;

[0054] (2) Perform cooling treatment on the reaction device, control the temperature in the reactor to be 5-10°C, and the pressure to be 0.03-0.05MPa;

[0055] (3) Accurately weigh sulfur dioxide and make it flow into the reaction kettle with an air flow of 65g / min, and start stirring at the same time, the mixer speed is 115r / min, after reacting for 30min, adjust the internal pressure of the reaction device to be a negative pressure of 0.03-0.05MPa;

[0056] (4) Fully mix the reacted materials for 5 minutes, then filter at normal pressure, and fill to obtain pyridine sulfur dioxide. During filling, the temperature in the reactor is 5-15° C. (stop cooling).

Embodiment 3

[0058] Prepare pyridine sulfur dioxide of the present invention, comprise the steps:

[0059] (1) Take 80 kg of pyridine with a high-precision electronic balance, filter and remove impurities with a 1 μm filter element, and put it into the reactor;

[0060] (2) Perform cooling treatment on the reaction device, control the temperature in the reactor to be 10-15°C, and the pressure to be 0.03-0.05MPa;

[0061] (3) Accurately weigh sulfur dioxide and allow it to flow into the reaction kettle with an air flow of 55g / min, and simultaneously start stirring, the stirrer rotating speed is 120r / min, after reacting for 30min, adjust the internal pressure of the reaction device to be a negative pressure of 0.03-0.05MPa;

[0062] (4) Fully mix the reacted materials for 5 minutes, then filter at normal pressure, and fill to obtain pyridine sulfur dioxide. During filling, the temperature in the reactor is 10-20° C. (stop cooling).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com