Cooling integral roof panel and cooling integral roof comprising same

A roof panel and panel technology, applied in the direction of roof, roof ventilation, building roof, etc., can solve the problems of increasing cooling load, increasing heat, shortening building life, etc., and achieving the effect of reducing air-conditioning load and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

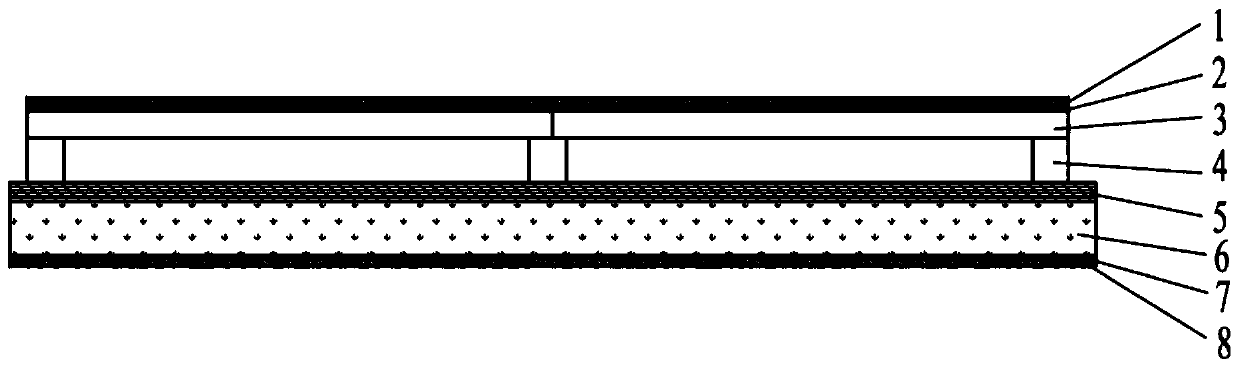

[0037] An integrated roof panel, such as figure 1 As shown, it includes an upper panel 1, a waterproof layer 2, and an air circulation layer that are connected to each other from top to bottom; Screw connection; the upper panel 1 is selected from color steel plate, cement tile or glass fiber panel, etc., preferably a surface layer material with good thermal conductivity, such as color steel plate, which can promote the heat absorption of the phase change layer during the day, and the phase change layer at night The purpose of rapid heat dissipation; the waterproof layer 2 is a synthetic polymer waterproof membrane or a modified asphalt waterproof membrane.

[0038] During specific implementation, the air circulation layer includes the phase change layer 3, the ventilation layer 4 and the base layer connected in sequence, and the air circulation layer can strengthen the air circulation, so that the heat of the phase change layer 3 can be dissipated as soon as possible.

[0039...

Embodiment 2

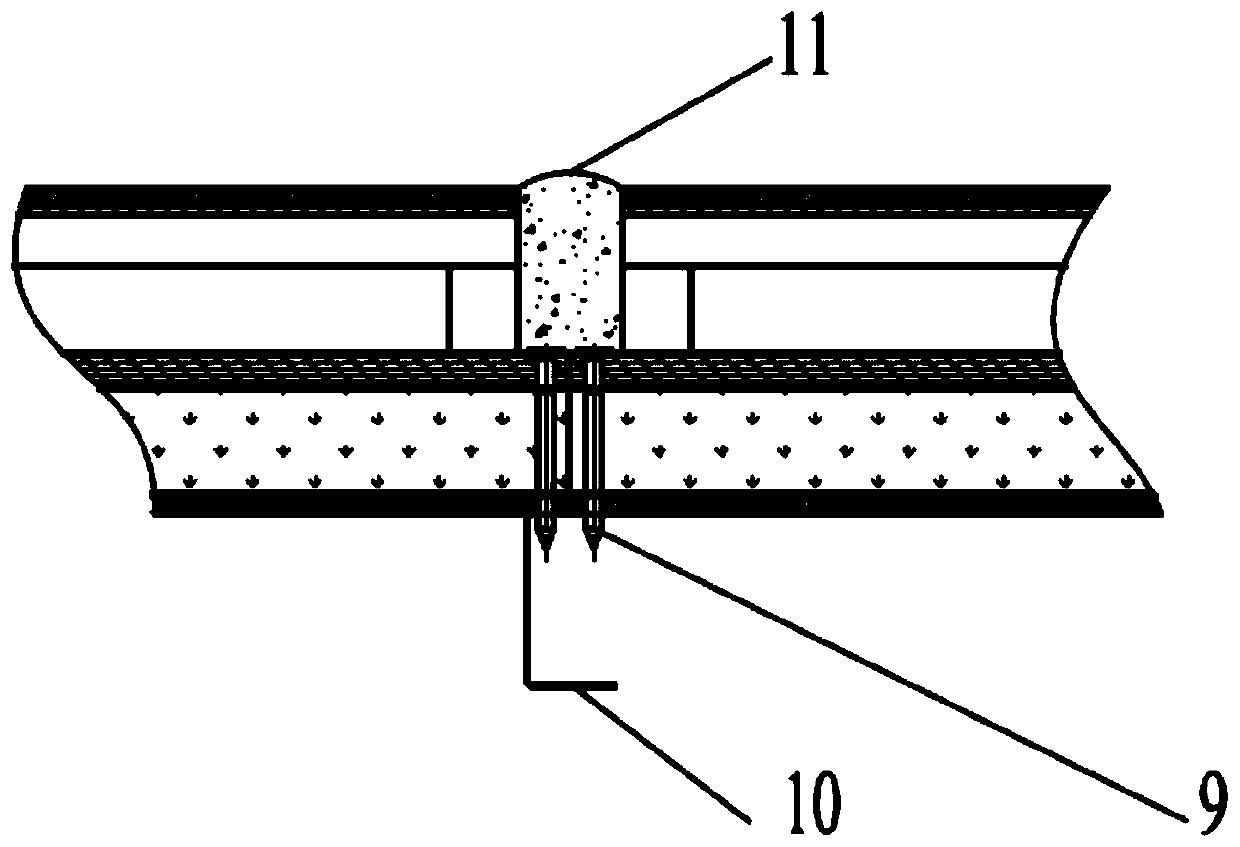

[0048] figure 2 It is a schematic cross-sectional diagram of the connection of two cooling integrated roof panels and their connection with the roof truss, as shown in figure 2 As shown, the joint of two integrated roof panels forms a concave-convex surface, which is connected to the light steel keel beam 10 through self-tapping screws 9, and can also be connected to the wooden beam 10; the gap between the two integrated panels Partially use foam glue and sealant 11 (such as building sealant, commercially available) to seal.

[0049] In the actual implementation process, the cooling integrated roof panel of the present invention can also be prefabricated in a factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com