Kiln car kiln tool for firing foam ceramics

A technology for foamed ceramics and kiln car, applied in the field of kiln car and kiln furniture, can solve the problems of inability to meet automatic production, increase the weight of triangular baffles, and cannot use a manipulator, and achieve the effects of realizing mechanized automation, saving materials, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

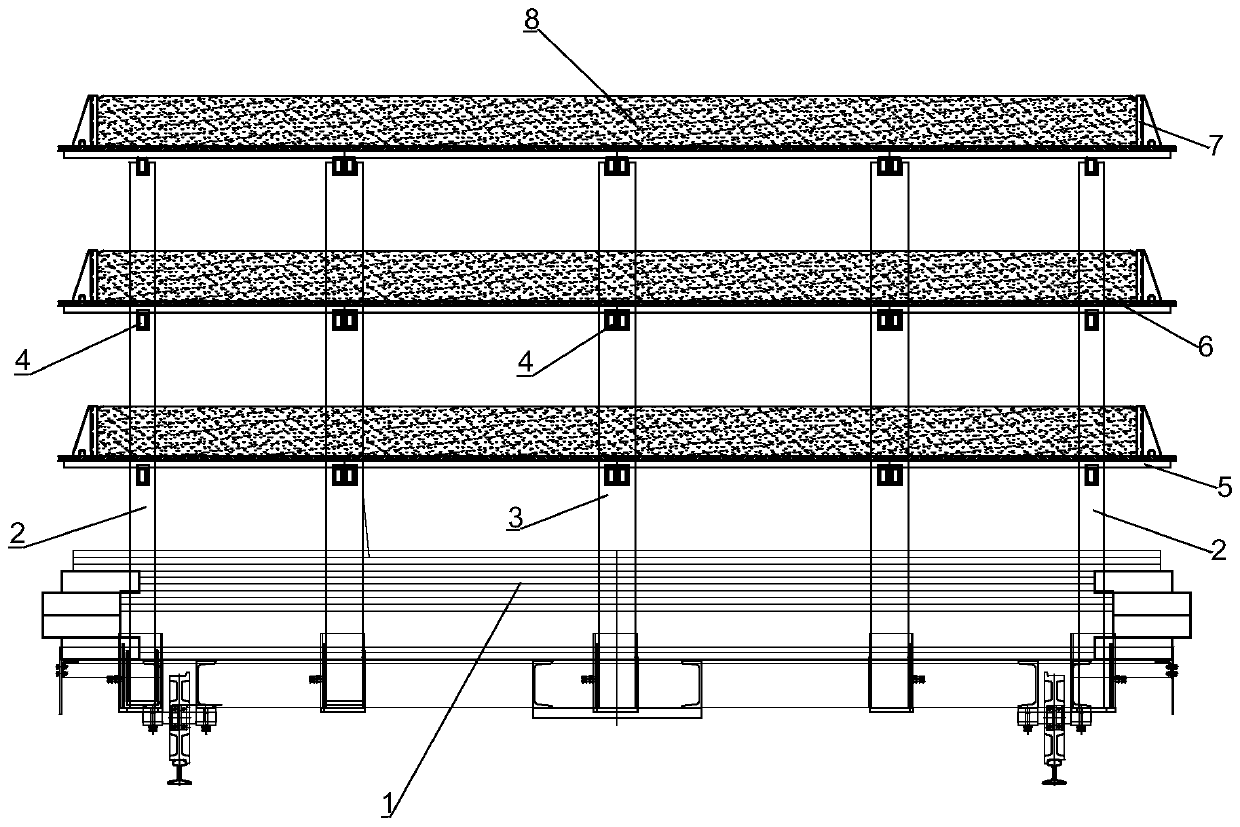

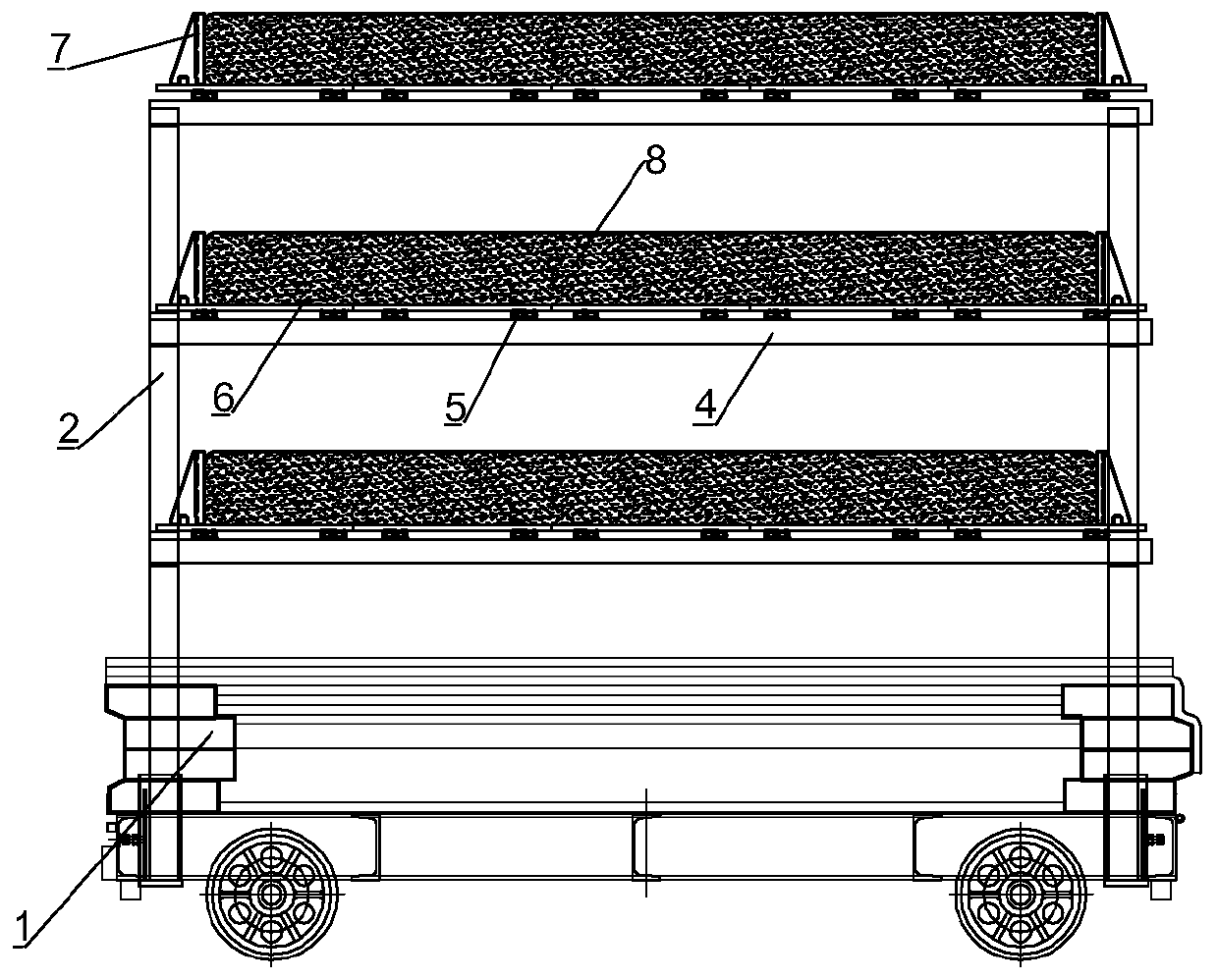

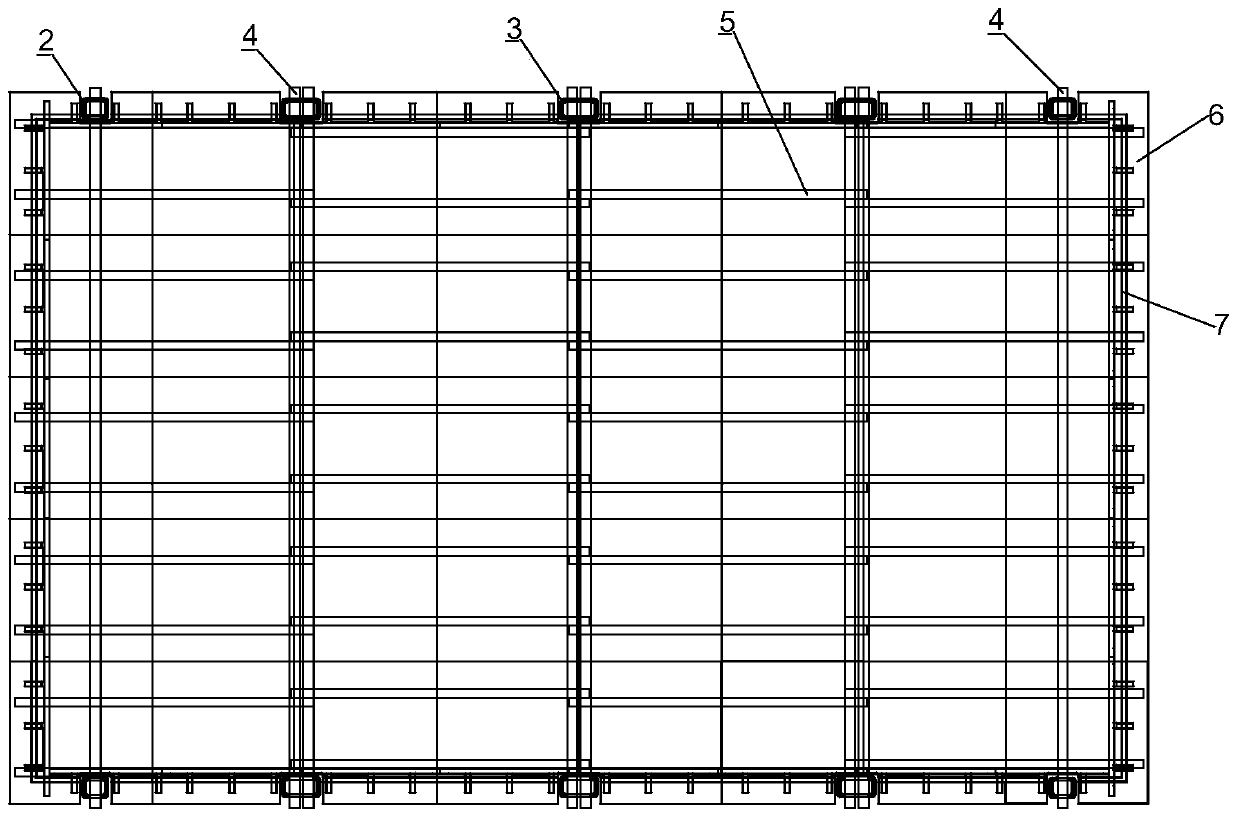

[0028] refer to Figure 1-Figure 13 , a kiln car kiln furniture for firing foam ceramics, comprising a kiln car 1, 10 columns are arranged on the kiln car 1, and in the forward direction of the kiln car, the columns on the left and right sides are A-shaped columns 2, The column between the A-type columns 2 is the B-type column 3, and there are three layers of layer holes on both the A-type column 2 and the B-type column 3, and the layer holes on the A-type column 2 are used to erect a main beam 4. The layer holes on the B-shaped column 3 are used to erect two main beams 4 side by side, and the auxiliary beams 5 are set on each layer of the main beams 4, and the three-story kiln furniture frame structure is composed of the columns, main beams and auxiliary beams. Lay pallets on all the auxiliary beams 5, each pallet is erected on every two auxiliary beams 5 respectively, all the pallets are assembled to form the bottom plate of the shaping trough for firing foam ceramics, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com