Concrete structure full-life performance intelligent sensing and degradation warning system and method

A technology for concrete structures and early warning systems, applied in transmission systems, closed-circuit television systems, alarms, etc., can solve the problems of misjudgment of critical states of reinforced concrete structures, inaccurate test results, etc., and achieve the effect of improving deterioration and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

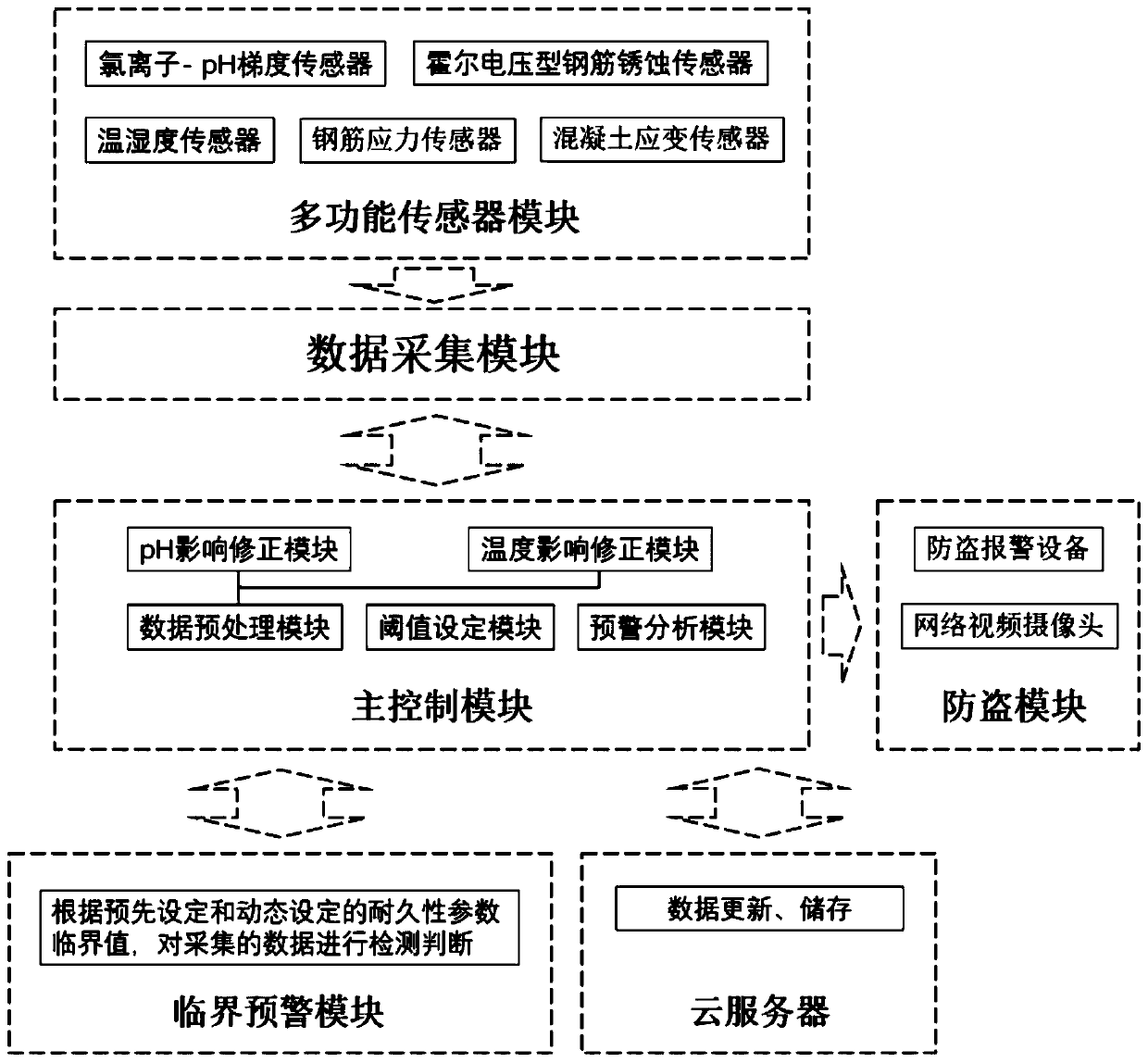

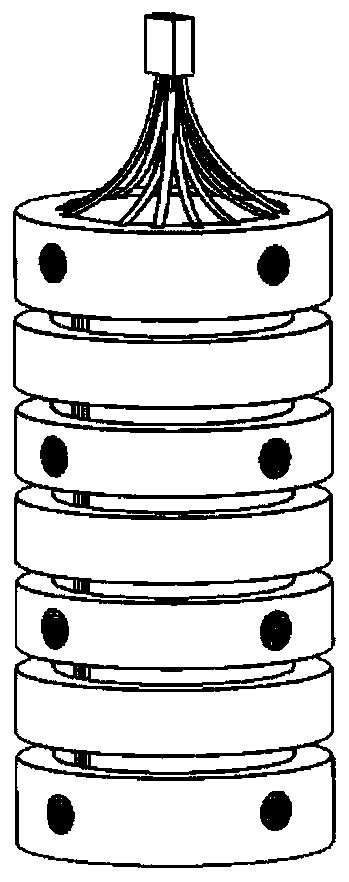

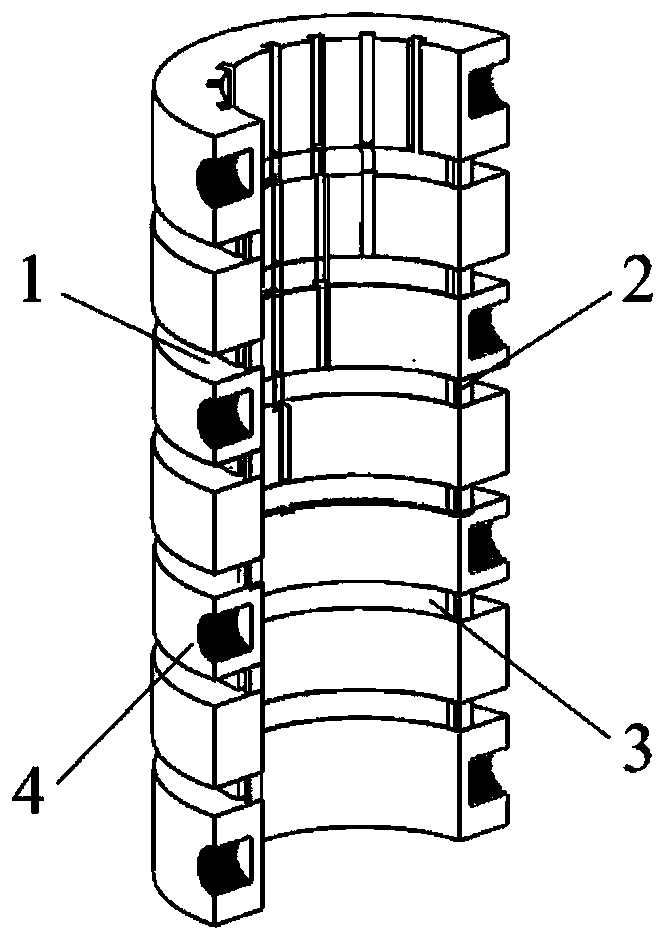

[0058] Embodiment 1. This embodiment discloses a concrete structure life-span performance intelligence perception and deterioration early warning system, such as figure 1 As shown, it includes a main control module, a multifunctional sensor module, an anti-theft module and a critical early warning module. The multifunctional sensor module, the antitheft module and the critical early warning module are all connected to the main control module. Inside the structure, including temperature and humidity sensors, chloride ion-pH gradient sensors, Hall voltage type steel corrosion sensors, steel stress sensors and concrete strain sensors; among them, the temperature and humidity sensors, steel stress sensors, and concrete strain sensors are used to monitor the temperature of concrete , humidity, steel bar stress, concrete strain and other parameters, the chloride ion-pH gradient sensor is used to detect the chloride ion content and pH value at different depths in the concrete, and the...

Embodiment 2

[0090] Embodiment 2. Based on the intelligent perception and deterioration early warning system for the life-span performance of concrete structures proposed in embodiment 1, this embodiment discloses a corresponding early warning method, which specifically includes the following steps:

[0091] Step 1, collect concrete state data based on the multifunctional sensor module, the state data includes temperature, humidity, chloride ion concentration, pH value, steel bar corrosion parameters, steel bar stress and concrete strain data, and pre-process the collected concrete state data deal with;

[0092] Step 2. Correcting the collected concrete internal pH value based on the temperature to obtain accurate monitoring results of the concrete internal pH value;

[0093] Step 3, based on the temperature and pH value, correct the collected chloride ion concentration information inside the concrete to obtain accurate monitoring results of the chloride ion content inside the concrete;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com