Laser welding quilting seam quality detection platform

A technology of laser welding and detection platform, which is applied in the direction of optical testing for flaws/defects, measuring devices, and material analysis through optical means, and can solve problems such as low detection efficiency, difficult detection of welds on the back of the welding plate, and high equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

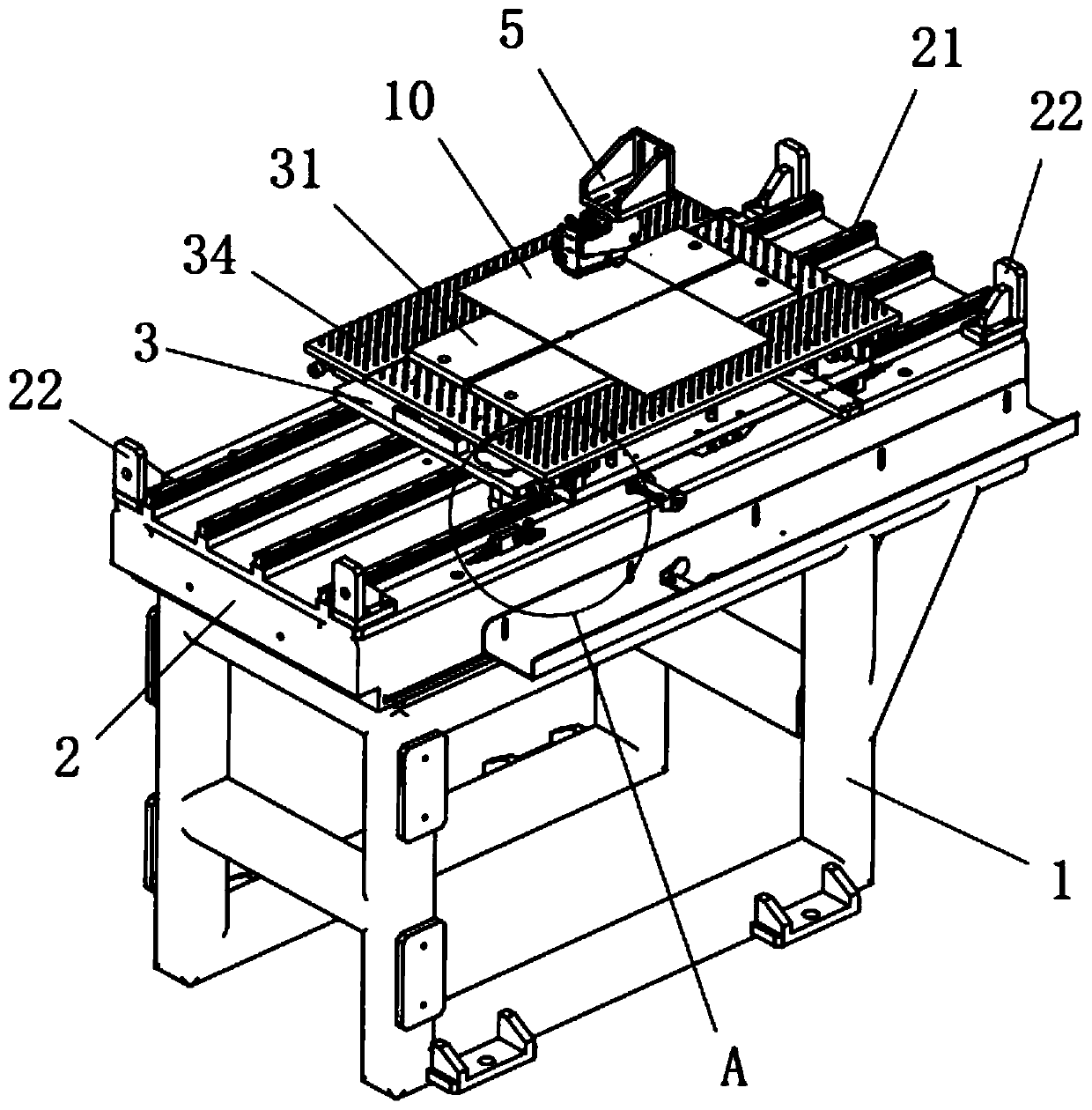

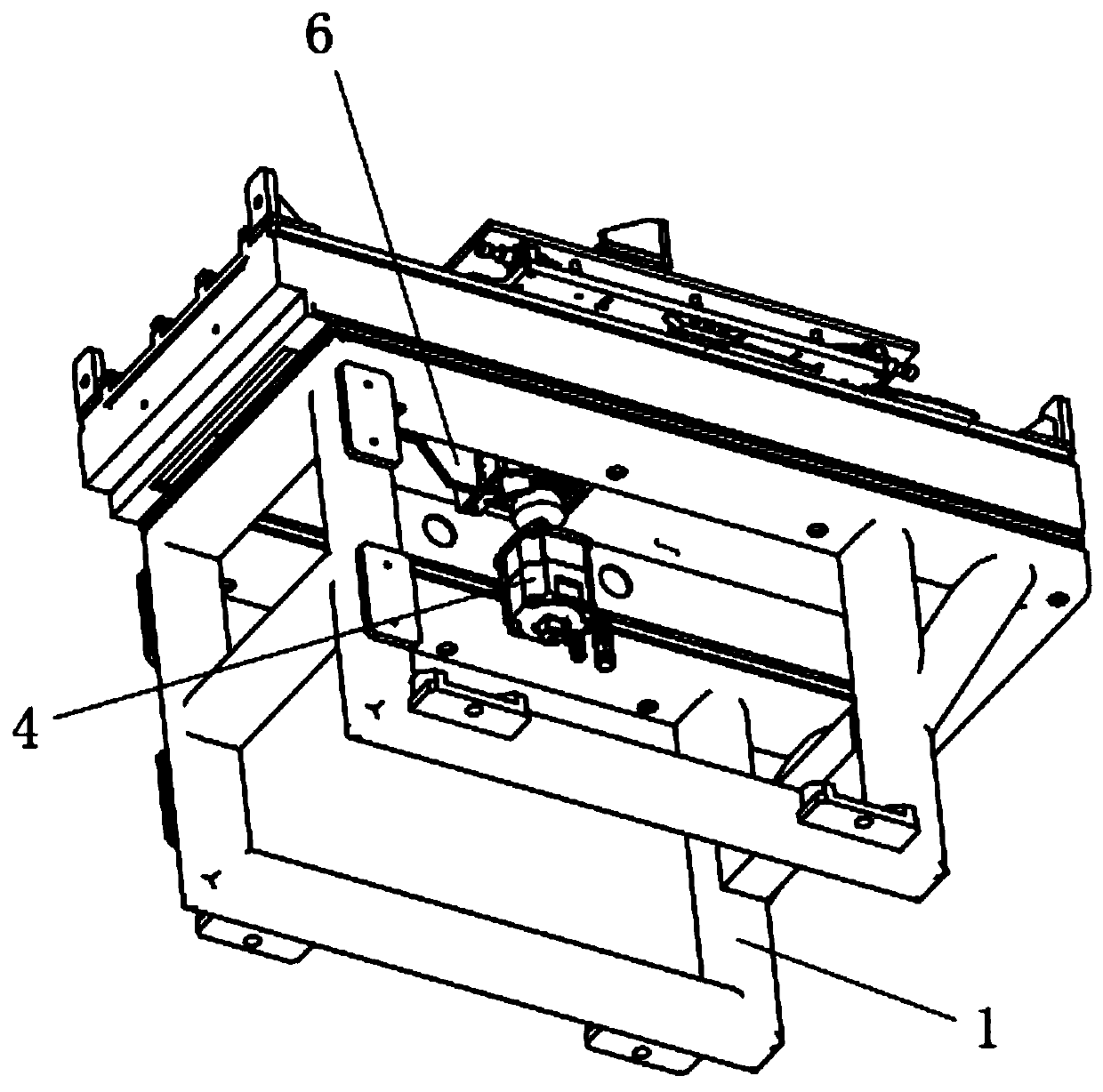

[0017] as attached Figure 1-3 As shown, a laser welding quilting quality testing platform according to the present invention includes a platform 1, a base 2, a moving platen 3, a driving device 4, an upper detection component 5 and a lower detection component 6.

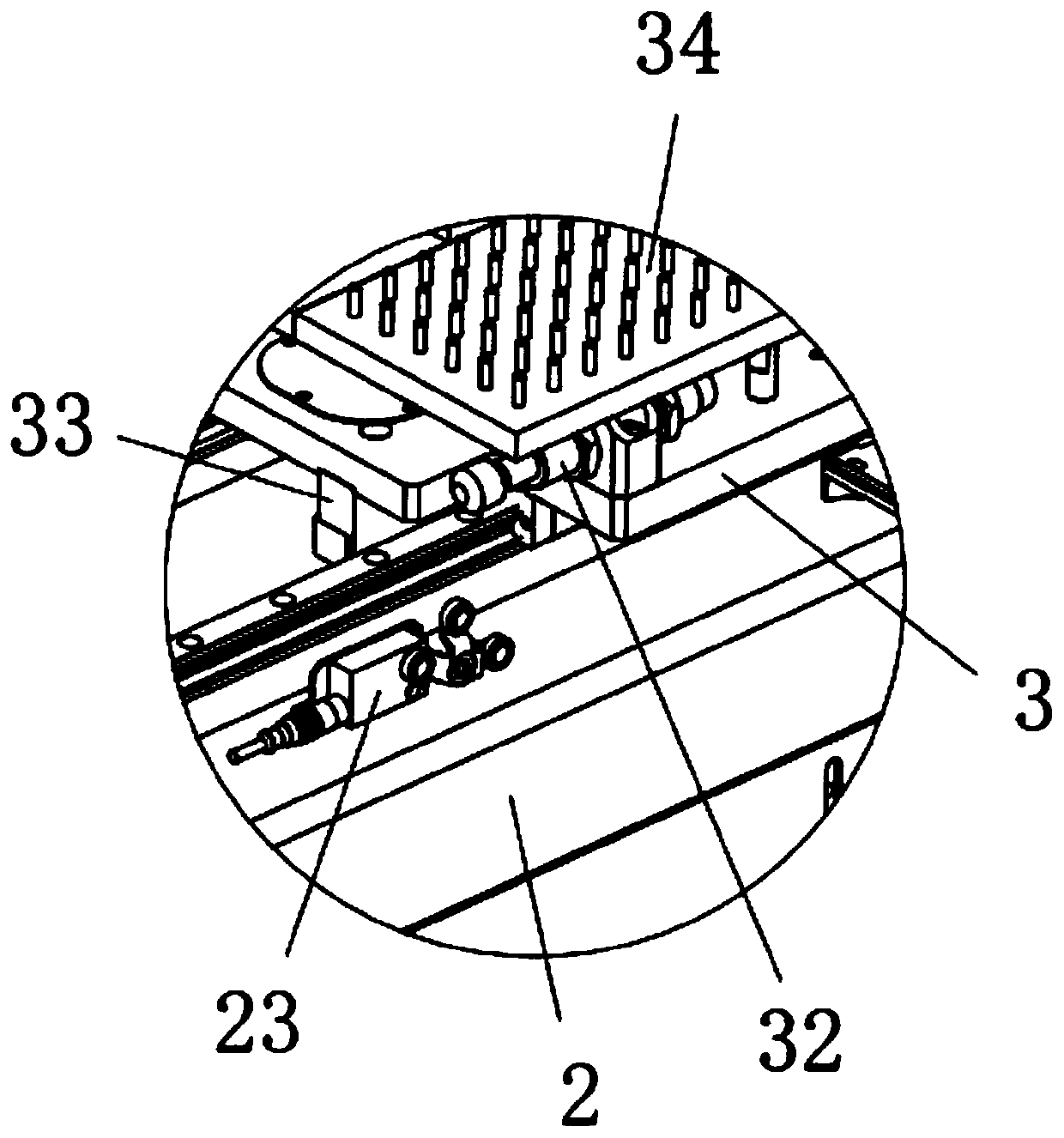

[0018] The base 2 is arranged on the stand 1, and the base 2 is provided with four slide rails 21 which are parallel to each other and equally spaced. The gear rack 33, the driving device 4 is a geared motor, and the geared motor cooperates with the gear rack 33 to drive the mobile platen 3 to move back and forth along the slide rail 21; the four corners of the base 2 are provided with mechanical limit blocks 22, The four corners of the movable platen 3 are provided with buffers 32, and the buffers 32 cooperate with the mechanical limit blocks 22 to limit and buffer the maximum front and rear travel of the movable platen 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com