Reliability allocation method

A distribution method and reliability technology, applied in the reliability/maintainability distribution of electrical and electronic products, and the mechanical field, can solve the problem that it is impossible to intuitively and directly guide design improvement ideas and methods, and it is difficult to follow-up improvement measures. Strong correlation, Does not take into account the unequal working hours of the constituent units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

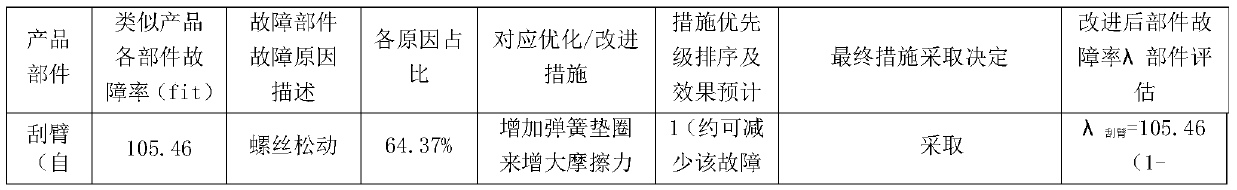

Examples

Embodiment Construction

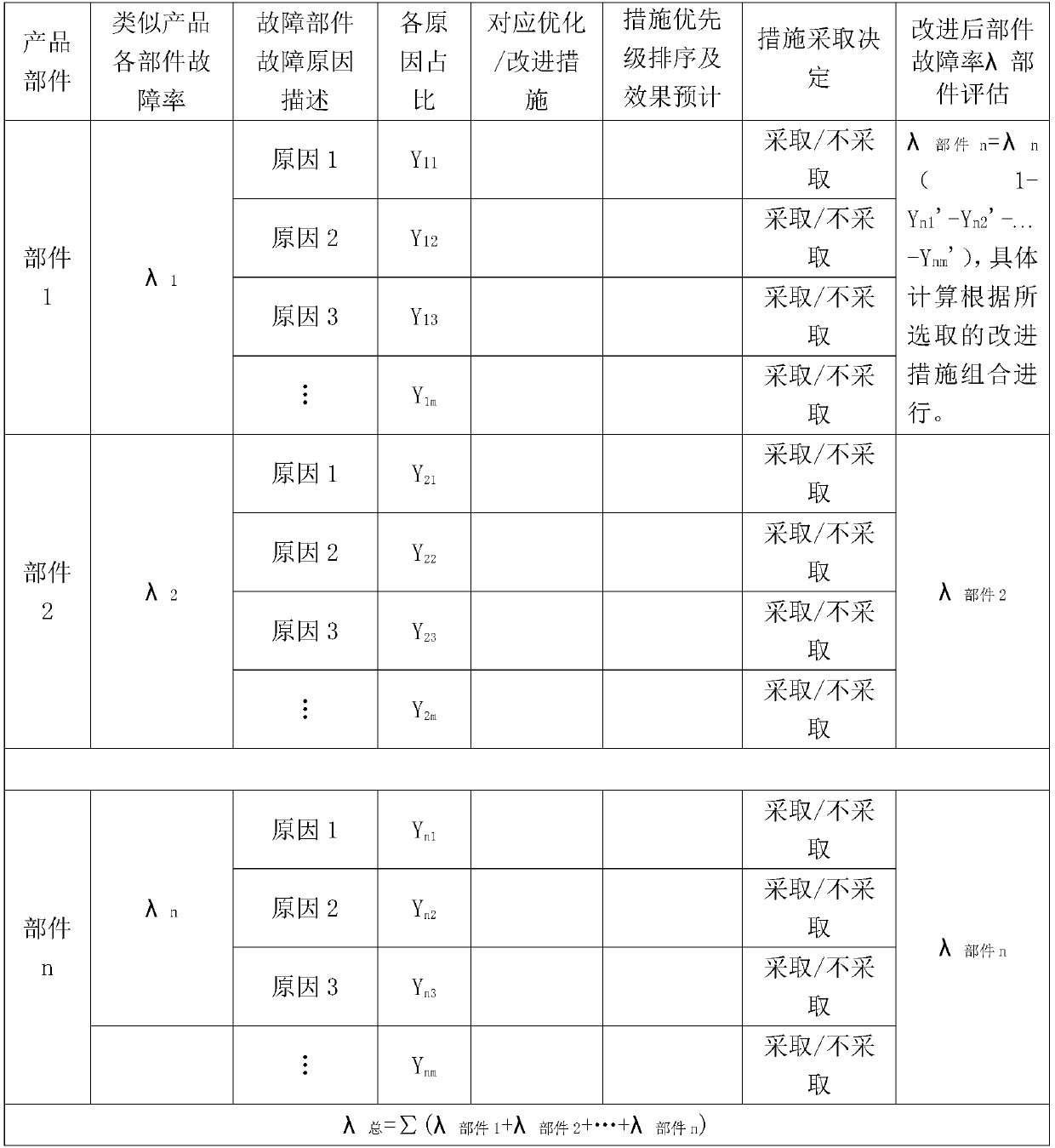

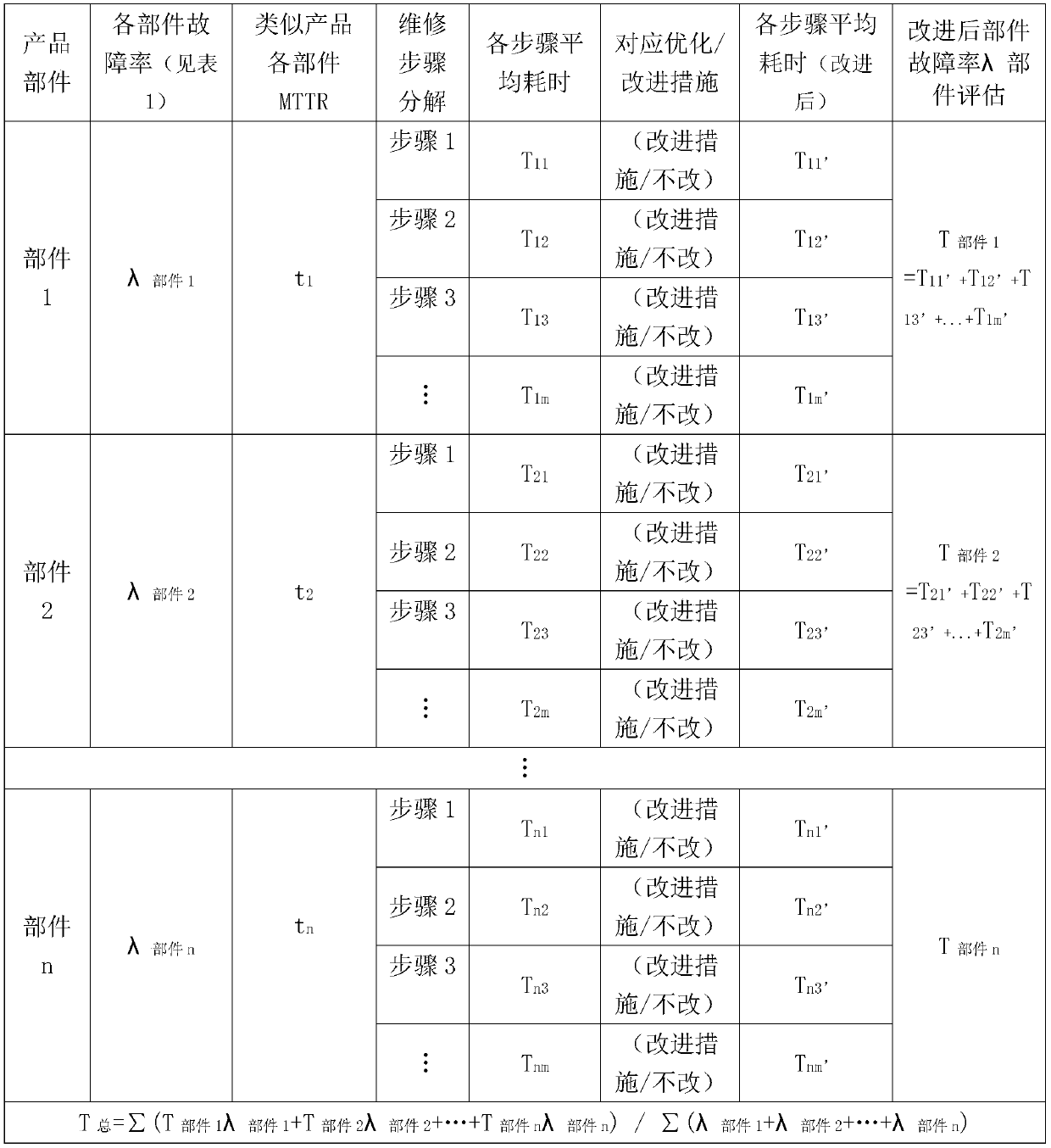

[0024] The present invention provides a reliability / maintainability allocation method, which includes the following steps:

[0025] 1) List the components of similar products that are the same or similar to the analyzed product and their failure rate λ 1 ...λ n ;

[0026] 2) Analyze all failure causes corresponding to each component of similar products and the proportion of each failure cause: list λ 1 The percentage of all failure causes in Y 11 ...Y 1m And the theoretically feasible improvement measures corresponding to each failure cause A 11 ...A 1m ; Repeat the above steps until λ is listed n The percentage of all failure causes in Y n1 ...Y nm And its corresponding theoretically feasible improvement measures A n1 ...A nm ;

[0027] 3) List feasible improvement measures for each failure cause;

[0028] 4) Prioritize the improvement measures based on the cost of the measures, the difficulty of implementation and the expected reliability effects: carry out the cost rise and fall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com