Cable cooling system used for charging gun

A technology of cooling system and charging gun, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of low charging efficiency, short service life, and large heat generation of cables, so as to prolong the service life, realize self-cooling, and increase heat dissipation and conduction. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

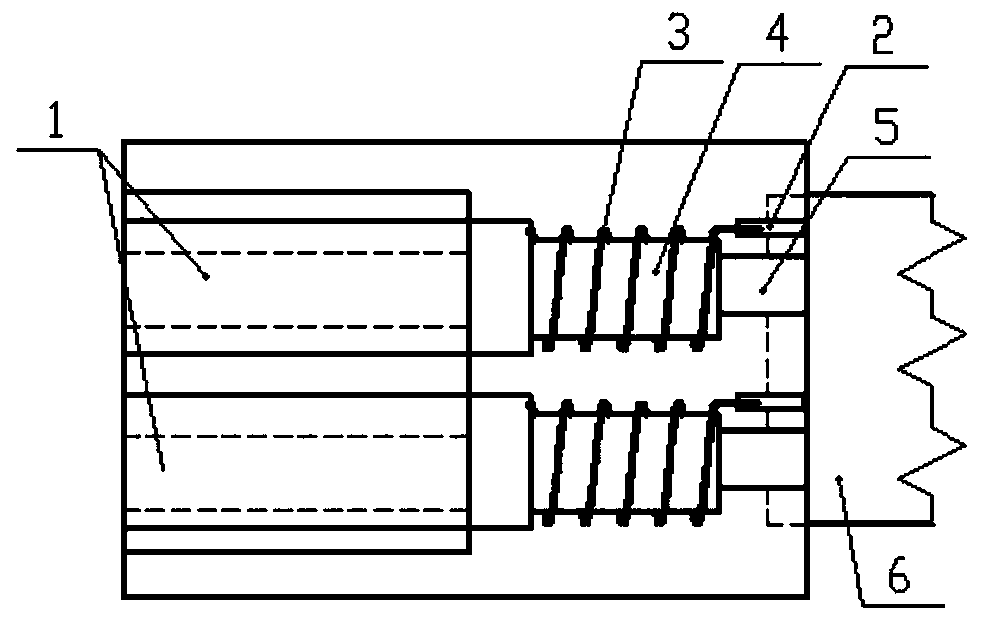

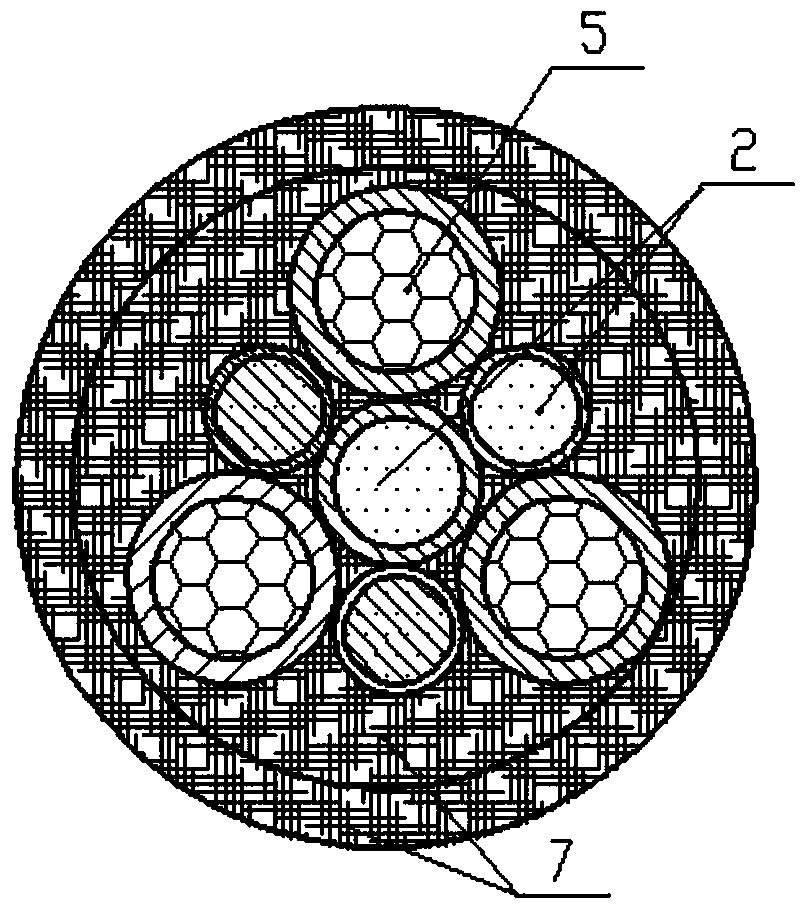

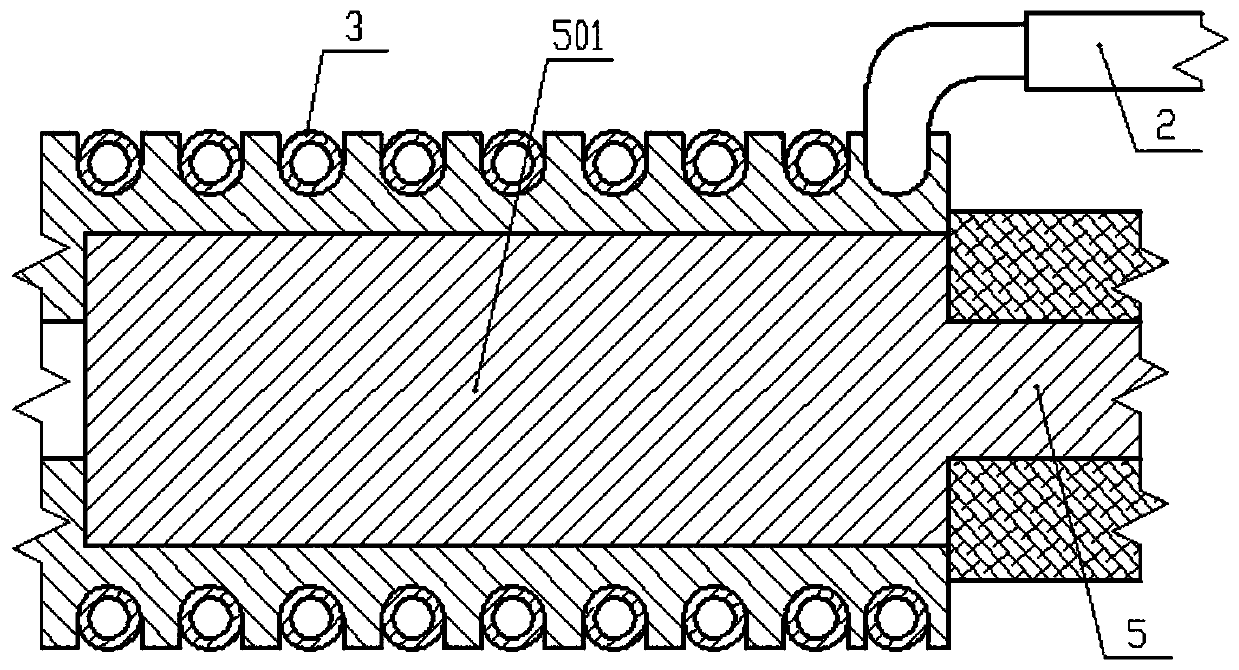

[0018] Such as figure 1 As shown in —2, a cable cooling system for a charging gun mainly includes an insulating hose 2 filled with an insulating cooling liquid inside, and the insulating hose 2 is bundled with the wires 5 in the cable 6 and is insulated The gap between the hose 2 and the wire 5 is filled with a filler with good insulation and heat dissipation to conduct heat conduction and transfer the heat out. The surface of the cable is wrapped with several layers of fillers, so that the fillers are in direct contact with the outside air and conduct heat away as soon as possible. The gaps and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com