Annular channel structure between stator and rotor of shielded motor

An annular flow channel, shielded motor technology, applied in the direction of magnetic circuit shape/style/structure, electric components, electromechanical devices, etc., can solve the difficulty of further improving the speed and power density of shielded motors, increase cooling measures and structural weight, and reduce shielding. The reliability of motor operation and other issues can be reduced to reduce fluid friction loss, improve cooling performance, and improve cooling and heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

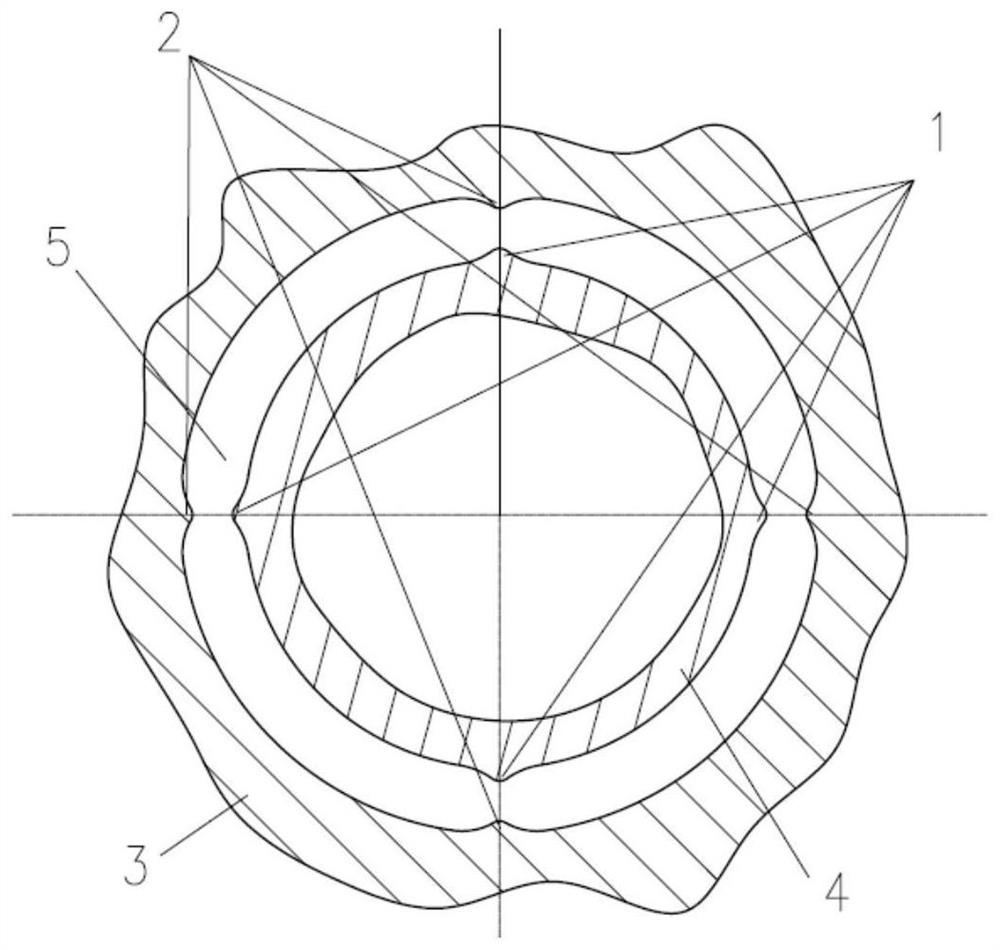

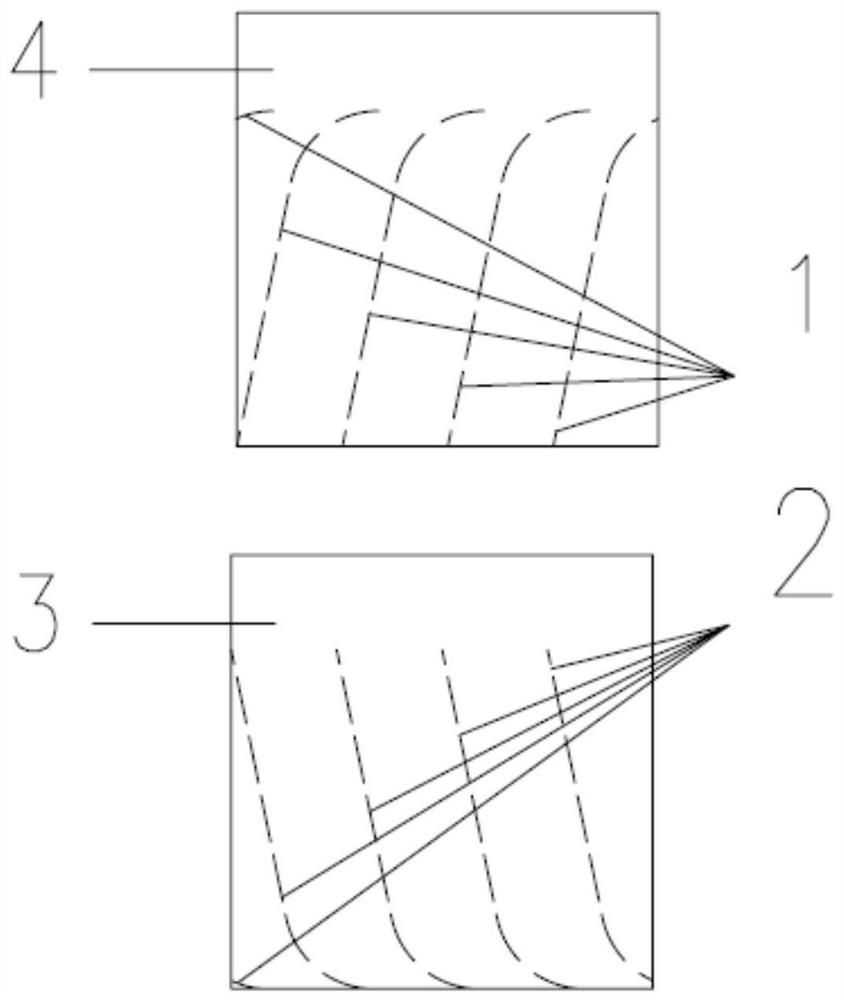

[0051] Figure 1 ~ Figure 2 It is a schematic diagram of the cross-section and the unfolded structure of the annular flow passage structure between the stator and the rotor of the shielded motor provided in Embodiment 1 of the present invention. Such as Figure 1 ~ Figure 2 As shown, the annular flow channel structure between the stator and rotor of the shielded motor provided by the present invention includes: a stator shielding sleeve (generally made of metal material) 3 with discontinuous flow guide ribs 2 on the inner cylindrical surface, and a discontinuous flow guide rib on the outer cylindrical surface. The rotor shielding sleeve (usually metal material) 4 of the rib 1, and the annular flow channel 5 between the stator shielding sleeve and the rotor shielding sleeve.

[0052] figure 1 The medium fluid flows from top to bottom perpendicular to the paper surface, and the rotor rotates clockwise; figure 2 The medium fluid flows from top to bottom along the paper, and t...

Embodiment 2

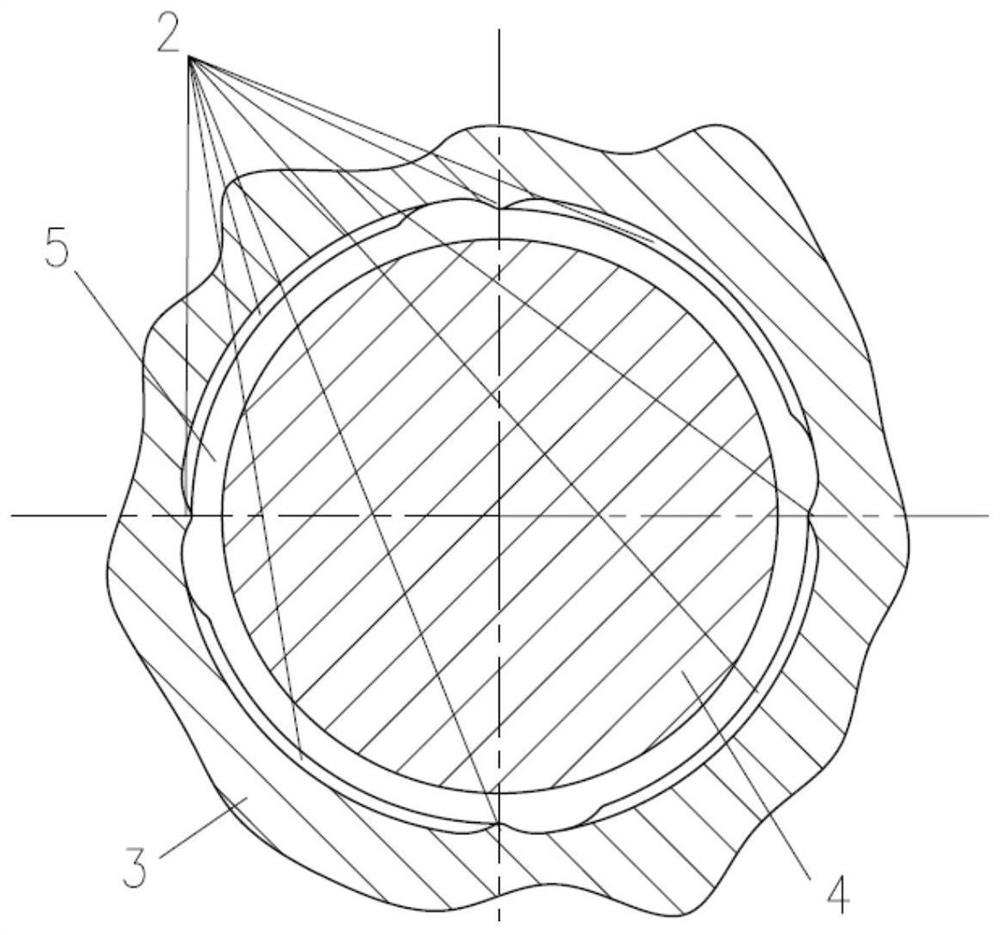

[0054] Figure 3 ~ Figure 4 It is a schematic diagram of the cross-section and the unfolded structure of the annular flow passage structure between the stator and the rotor of the shielded motor provided by Embodiment 2 of the present invention. Such as Figure 3 ~ Figure 4 As shown, the annular flow channel structure between the stator and rotor of the shielded motor provided by the present invention includes: a stator shielding sleeve 3 with a continuous guide rib 2 on the inner cylindrical surface, a rotor shielding sleeve 4 without a guide rib on the outer cylindrical surface, and a stator The annular flow channel 5 between the shielding sleeve and the rotor shielding sleeve.

[0055] image 3 The medium fluid flows from top to bottom perpendicular to the paper surface, and the rotor rotates clockwise; Figure 4 The medium fluid flows from top to bottom along the paper, and the rotor rotates from left to right along the paper.

[0056] In other embodiments of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com