Vane pump

A technology of vane pumps and pump chambers, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as deterioration of vehicle installation, achieve good pump efficiency, prevent instantaneous leakage, and be easy to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

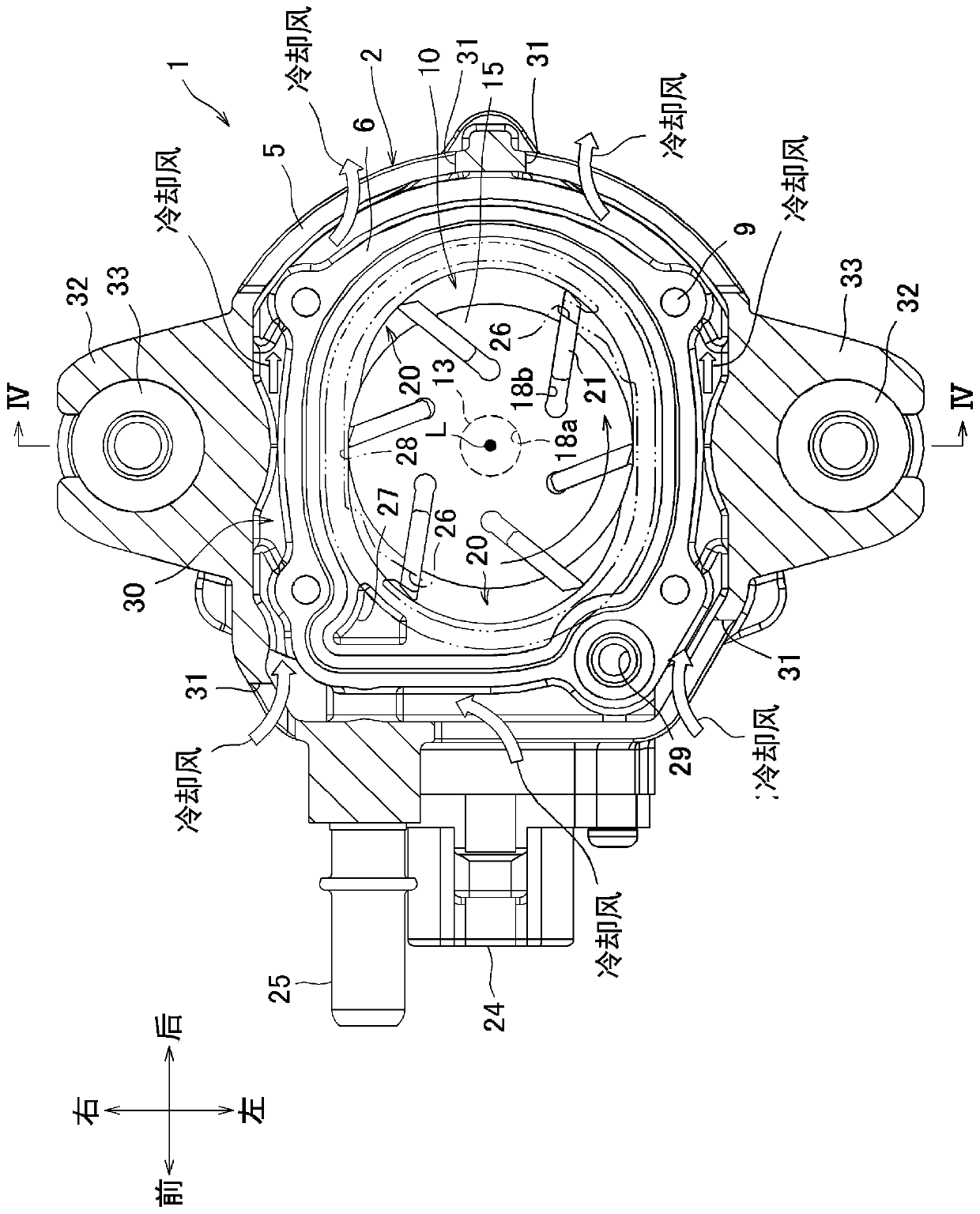

[0063] Figure 5 It is a schematic diagram which shows the planar shape of the accommodation space 10 in 1st Embodiment.

[0064] Basically, the housing space 10 of the vacuum pump 1 according to the present embodiment has the same structure as that of Patent Document 2, and is elliptical in plan view, and is represented by the following equation (1) on the X-axis and Y-axis planes, for example.

[0065] x 2 / A 2 +Y 2 / B 2 =1...(1)

[0066] Here, A / B is the ratio of the major axis to the minor axis of the ellipse. The major axis of the storage space 10 corresponds to the "direction of parallel arrangement of the pump chambers" in the present invention, and the minor axis of the storage space 10 corresponds to the "direction perpendicular to the parallel arrangement direction" in the present invention.

[0067] The difference from the storage space of Patent Document 2 is as follows.

[0068] In the present embodiment, the internal dimension of the elliptical housing spa...

no. 2 approach

[0084] Figure 7 are the sum and Figure 6 The corresponding partial enlargement.

[0085] In the present embodiment, buffer surfaces C are formed at the boundaries between the elliptical surface B corresponding to the discharge side of each pump chamber 20 and each sealing surface A indicated by point b. The buffer surfaces C each have a cross-sectional arc shape with a radius Rc having a center p outside the housing space 10 , and the arc surface B and the sealing surface A are connected via the buffer surfaces C. By setting the position of the above-mentioned center p, the buffer surface C is curved in a direction opposite to the curved shape of the arcuate surface B and the sealing surface A. Specifically, the arcuate surface B and the sealing surface A are concave when viewed from the storage space 10 , whereas the buffer surface C is convex when viewed from the storage space 10 .

[0086] Therefore, when the vacuum pump 1 is in operation, the tips of the vanes 21 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com