Multilayer electronic component and method for manufacturing multilayer electronic component

An electronic component, layered technology, applied in fixed capacitor parts, transformer/inductor parts, electrical components, etc., can solve problems such as stray capacitance, inconvenience, electrode plastic deformation, etc., to suppress defective products, easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

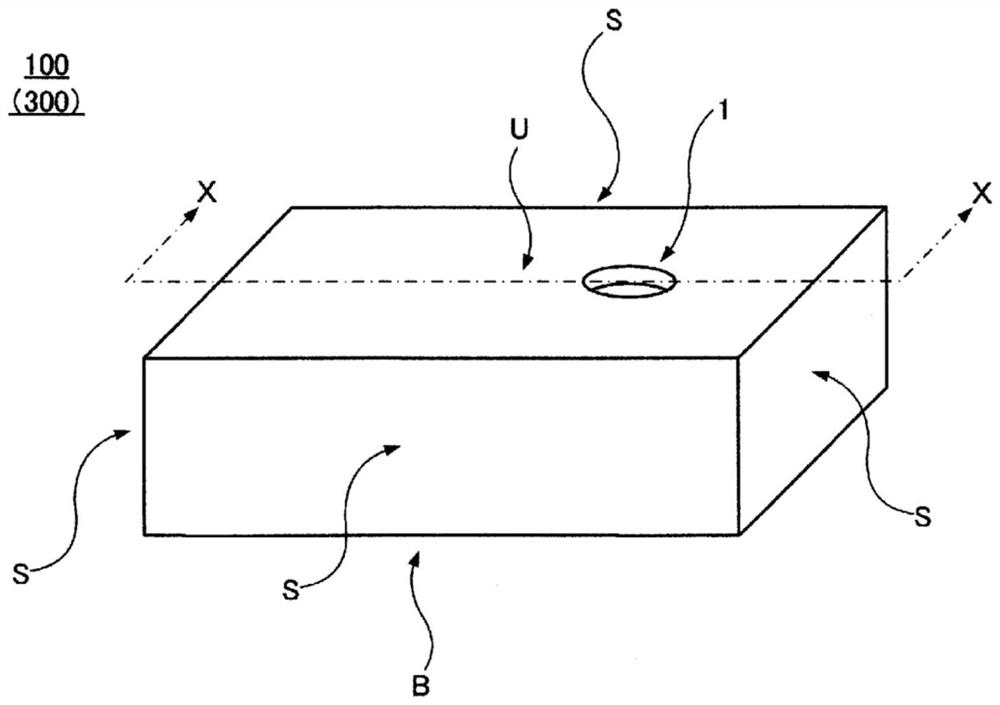

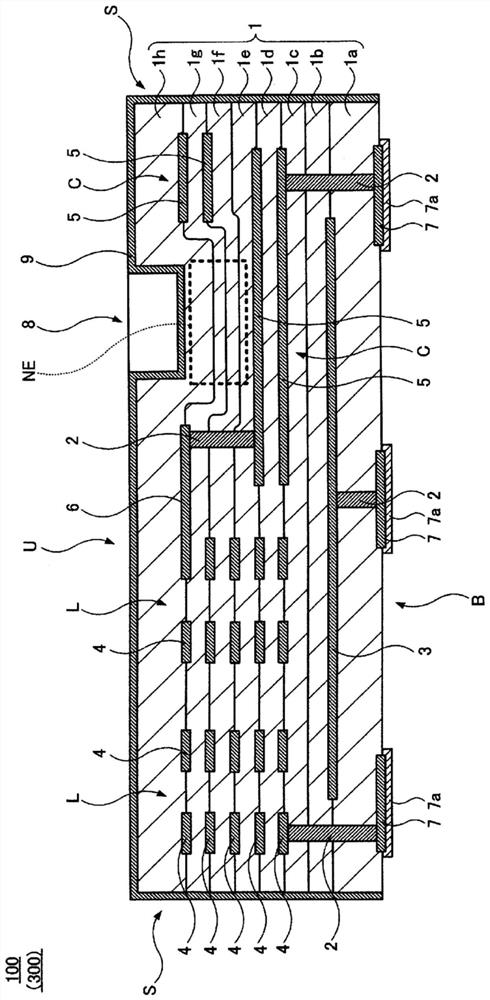

[0040] exist figure 1 , figure 2 The multilayer electronic component 100 according to the first embodiment is shown in . in, figure 1 It is a perspective view of the multilayer electronic component 100 . figure 2 is a cross-sectional view of the laminated electronic component 100, showing figure 1 The dotted line X-X part.

[0041] The multilayer electronic component 100 is, for example, a multilayer LC filter in which capacitors and inductors are formed to constitute a predetermined LC filter circuit. However, the type of the multilayer electronic component 100 is arbitrary, and is not limited to the multilayer LC filter.

[0042] The laminated electronic component 100 is provided with the laminated body 1 in which the ceramic layers 1a-1h were laminated|stacked. The laminated body 1 includes a bottom surface B, a top surface U, and four side surfaces S connecting the bottom surface B and the top surface U.

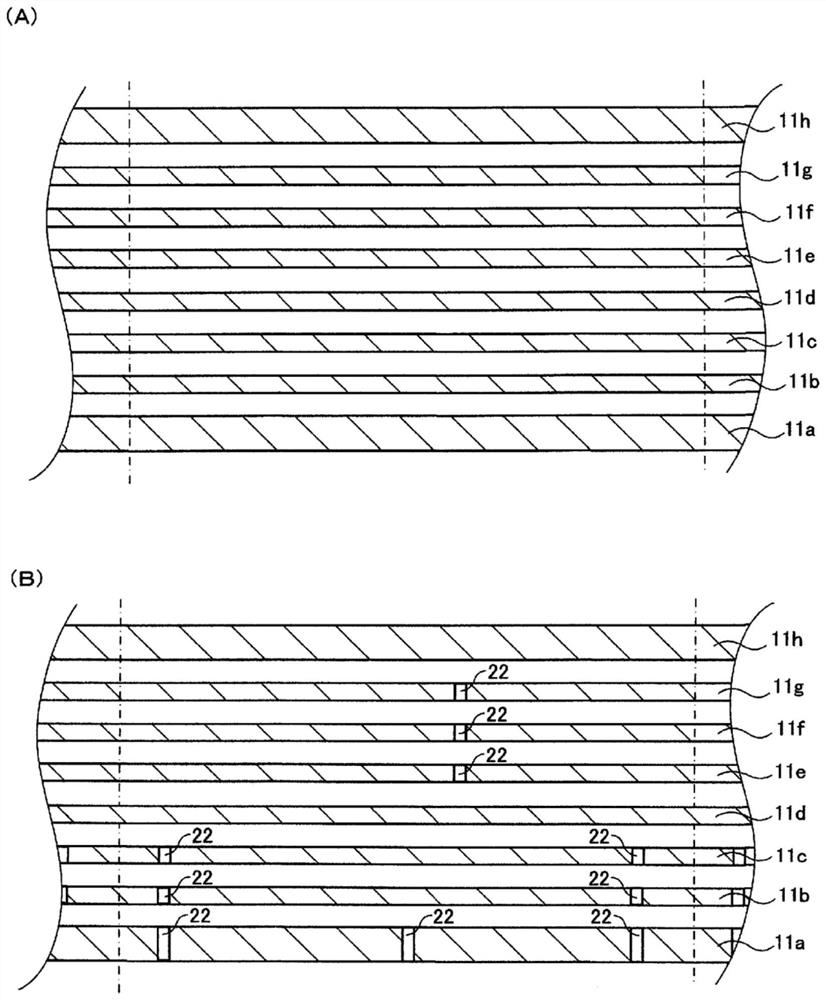

[0043] In this embodiment, the thicknesses of the ceram...

no. 2 Embodiment approach

[0081] Figure 7 A multilayer electronic component 200 according to the second embodiment is shown. in, Figure 7 is a cross-sectional view of the multilayer electronic component 200 .

[0082] The manufacturing method of the multilayer electronic component 200 is partially changed from the manufacturing method of the multilayer electronic component 100 according to the above-mentioned first embodiment. Specifically, in the first embodiment, the paste pattern 18 is pressed into the top surface of the aggregate substrate-like unfired laminate 11 in advance, and the paste pattern 18 is eliminated during firing to form the concave portion 8 . In the second embodiment, the concave portion 8 is formed by irradiating the top surface of the aggregated substrate-like unfired laminate 11 with laser light. Other manufacturing steps of the multilayer electronic component 200 are the same as those of the first embodiment.

[0083] By adopting the above manufacturing method, thus from ...

no. 3 Embodiment approach

[0086] The multilayer electronic component 300 according to the third embodiment was produced. The stacked electronic part 300 is made with figure 1 , figure 2 The multilayer electronic component 100 according to the first embodiment shown has the same structure and configuration, citing figure 1 , figure 2 to explain.

[0087] Also for the multilayer electronic component 300 , the manufacturing method is partially changed based on the manufacturing method of the multilayer electronic component 100 according to the first embodiment described above. Specifically, in the first embodiment, the concave portion 8 is formed by pressing the paste pattern 18 into the top surface of the aggregate substrate-like unfired laminate 11 in advance, and disappearing the paste pattern 18 during firing. In the third embodiment, the concave portion 8 is formed by press-fitting the convex portion formed on the inner bottom surface of the upper mold (not shown) into the top surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com