Packaging kit of flat ceramic membrane for filtration

A ceramic membrane and filter membrane technology, applied in the field of water pollution control, can solve the problem that the water output cannot reach the water permeability of the flat ceramic membrane surface, and achieve the effect of increasing the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

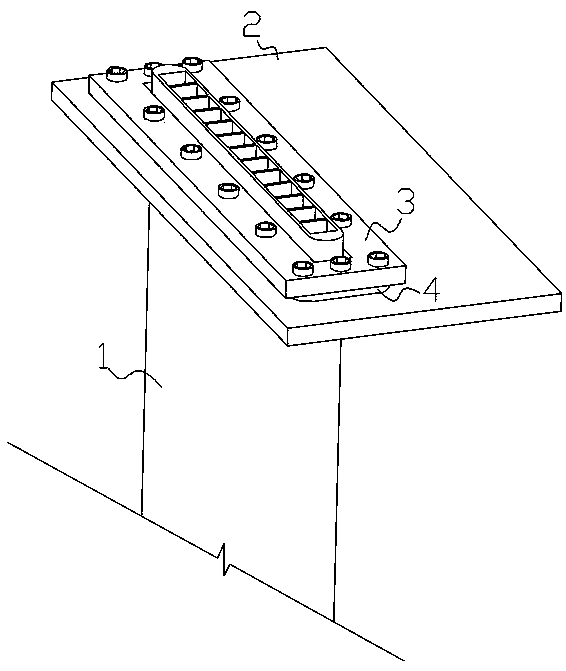

[0045] In this embodiment, a packaging kit for a flat ceramic membrane for filtration, as attached figure 1As shown, it includes a filter membrane 1 made of inorganic material, a sealed outer plate 2 made of metal, a sealed inner plate 3 made of metal and a sealing ring 4 made of rubber. The two ends of the filter membrane 1 adopt the same packaging structure. The sealing ring 4 is clamped and fixed between the sealing outer plate 2 and the sealing inner plate 3 . The filter membrane 1 passes through the combination of the sealing outer plate 2, the sealing inner plate 3 and the sealing ring 4. The outer surface of the filter membrane 1 is in close contact with the inner side of the expanded and deformed ring of the sealing ring 4, and is in close contact with the sealing outer plate. There is a gap between the plate 2 and the sealed inner plate 3 . When this structure is used to fix the filter membrane 1, when the high filtration temperature is higher than the packaging temp...

Embodiment 2

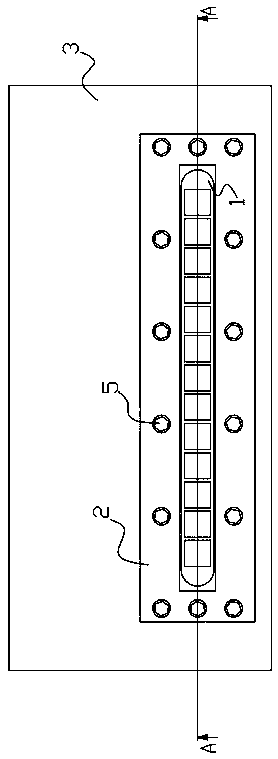

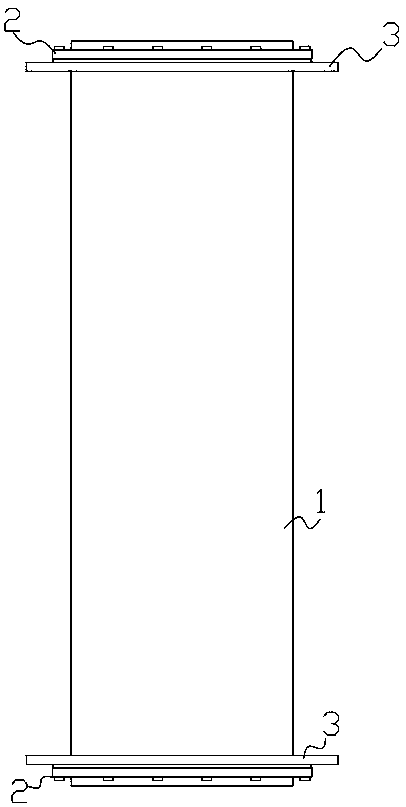

[0047] In this embodiment, a packaging kit for a flat ceramic membrane for filtration, as attached Figure 2~4 As shown, it includes a filter membrane 1 made of inorganic material, a sealed outer plate 2 made of metal, a sealed inner plate 3 made of metal and a sealing ring 4 made of rubber. The two ends of the filter membrane 1 adopt the same packaging structure. The sealing ring 4 is clamped and fixed between the sealing outer plate 2 and the sealing inner plate 3 . The filter membrane 1 passes through the combination of the sealing outer plate 2, the sealing inner plate 3 and the sealing ring 4. The outer surface of the filter membrane 1 is in close contact with the inner side of the expanded and deformed ring of the sealing ring 4, and is in close contact with the sealing outer plate. There is a gap between the plate 2 and the sealed inner plate 3 . When this structure is used to fix the filter membrane 1, when the high filtration temperature is higher than the packaging ...

Embodiment 3

[0054] In this embodiment, a packaging kit for a flat ceramic membrane for filtration, as attached Figure 7 As shown, it includes a filter membrane 1 made of inorganic material, a sealed outer plate 2 made of hard plastic material, a sealed inner plate 3 made of hard plastic material, and a sealing ring 4 made of rubber material. The two ends of the filter membrane 1 adopt the same packaging structure . The sealing ring 4 is clamped and fixed between the sealing outer plate 2 and the sealing inner plate 3 . The filter membrane 1 passes through the combination of the sealing outer plate 2, the sealing inner plate 3 and the sealing ring 4. The outer surface of the filter membrane 1 is in close contact with the inner side of the expanded and deformed ring of the sealing ring 4, and is in close contact with the sealing outer plate. There is a gap between the plate 2 and the sealed inner plate 3 . When this structure is used to fix the filter membrane 1, when the high filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com