Dissimilar metal laser cladding welding method for copper pipe and steel pipe

A laser cladding, dissimilar metal technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of low strength, easy leakage, unstable quality of welded joints, etc., to achieve a small heat affected zone, increase The effect of improving absorption rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

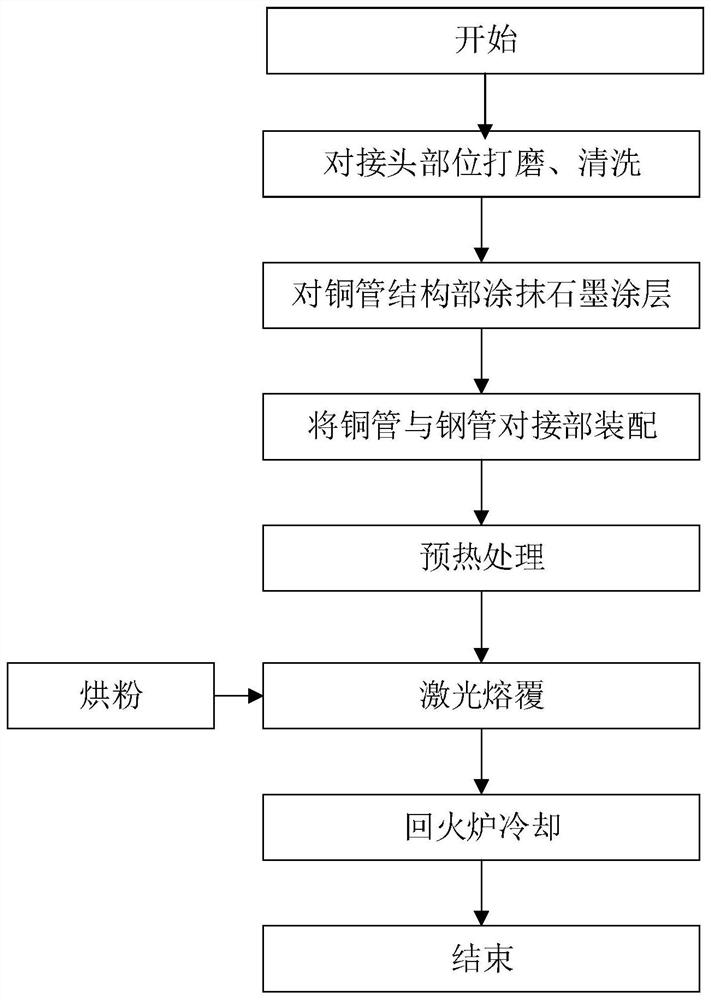

[0041] A dissimilar metal laser cladding welding method for copper pipes and steel pipes, comprising the following steps:

[0042] S1. Material preparation: Grind and clean the joints between the copper pipe and the steel pipe for connection;

[0043] S2. Send the welding powder into the powder drying furnace, and keep it warm for more than 3 hours at a temperature of 50°C~~100°C;

[0044] S3. Coat the joints on the copper pipe with graphite coating; use graphite coating as an intermediate transition coating, and pre-coat a layer of graphite coating on the joints of copper pipes to reduce the intensity of copper to light The reflection effect increases the laser absorption rate of copper, so that in the subsequent laser cladding, the welding part receives the laser as much as possible, obtains enough energy, and quickly melts the welding material and the base material. In addition to graphite coating, powder coatings such as white iron and tin, which have lower reflectivity t...

Embodiment 2

[0060] This embodiment is an implementation description of the welding parameters in step S6 in the first embodiment.

[0061] The welding process parameters are preferably: laser power 2.8-3.8KW, scanning speed 4-8mm / s, powder feeding volume 2.5-4.5g / min, spot diameter 2-3mm, shielding gas using argon, shielding gas flow 10- 20L / min. The model of laser cladding equipment is preferably METAL+1006, and its parameters during laser cladding are shown in Table 1:

[0062] Laser power (P) scanning speed Feeding volume Shielding gas flow Spot diameter 2.8-3.8KW 4~8mm / s 2.5-4.5g / min 10-20L / min 2-3mm

[0063] Table 1. Laser cladding process parameters

Embodiment 3

[0065] This example is a concrete description of the nickel-based alloy powder. Nickel-based alloy powder is preferably HR-Ni-S01 powder.

[0066] The composition of HR-Ni-S01 powder is recorded in mass percentage, as shown in the following table:

[0067] powder material Ni Ti Nb Cu Mo Cr Si Al Fe HR-Ni-S01 50 ~ 55 0.75 ~ 1.15 5 ~ 5.5 0.2 ~ 0.4 2.8 ~ 3.3 17 ~ 21 0.3 ~ 0.4 0.3 ~ 0.7 margin

[0068] Table 2. HR-Ni-S01 powder composition list

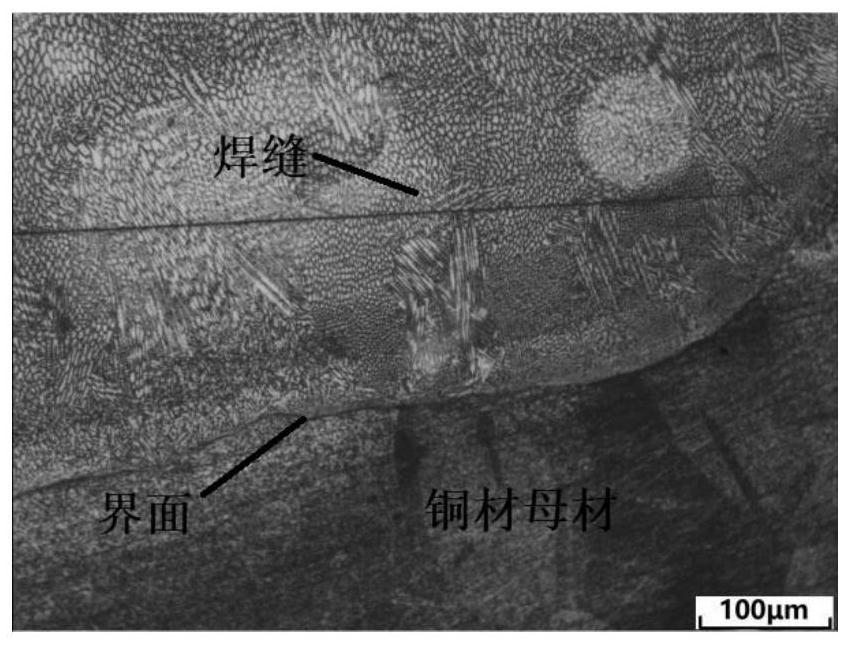

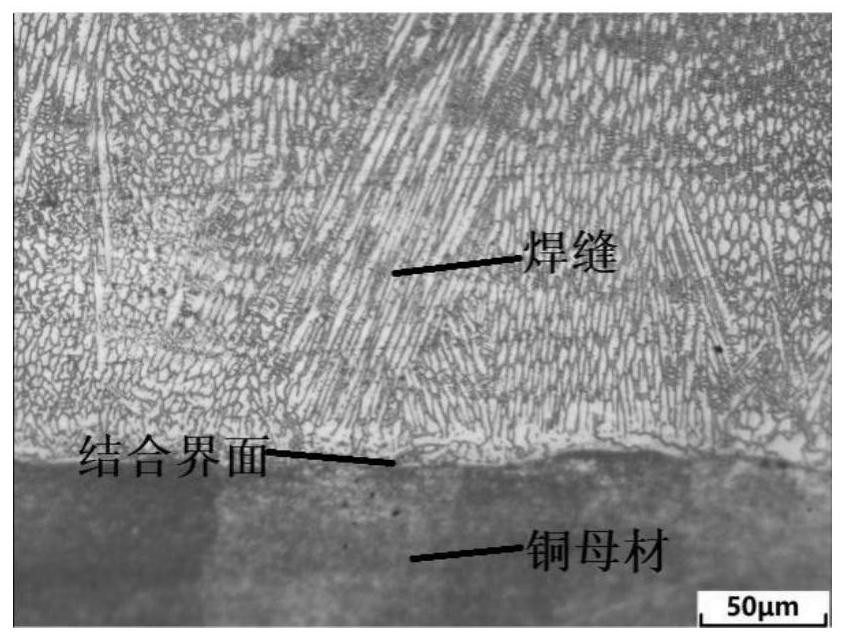

[0069] Due to the large difference in materials of copper pipes and steel pipes, the requirements for welding filler materials are relatively high. In the present invention, a nickel-based alloy powder with high content of Ni and Cr and good wettability with copper is selected as the welding material. Ni and Copper can melt infinitely, which improves the wettability, mutual melting and bonding between the weld and copper.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap