Shell and its preparation method and electronic equipment

A technology for electronic equipment and casing, applied in the field of casing and its preparation, can solve problems such as poor mechanical properties of casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] According to the method for preparing the shell in one embodiment, the machining allowance is low, and a shell with better mechanical properties can be obtained. Further, the housing is in a 2.5D or 3D shape. Furthermore, the housing is a 3D mobile phone housing. It should be noted that the casing is not limited to a mobile phone casing, and may also be a casing of other electronic devices in the technical field, for example, a casing of a tablet computer, a computing device, or an information display device. In a specific example, the housing is a 3D mobile phone back cover.

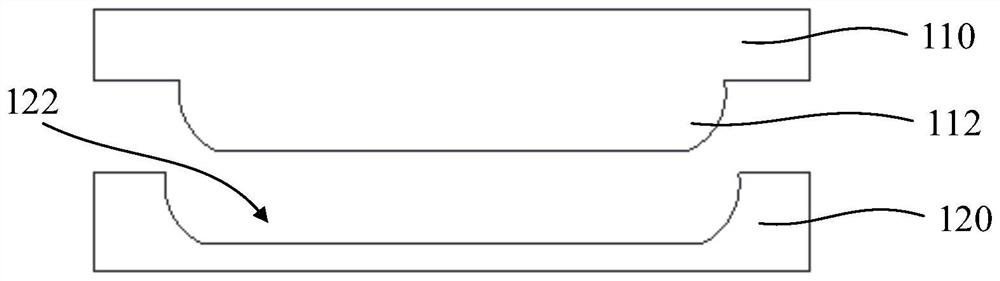

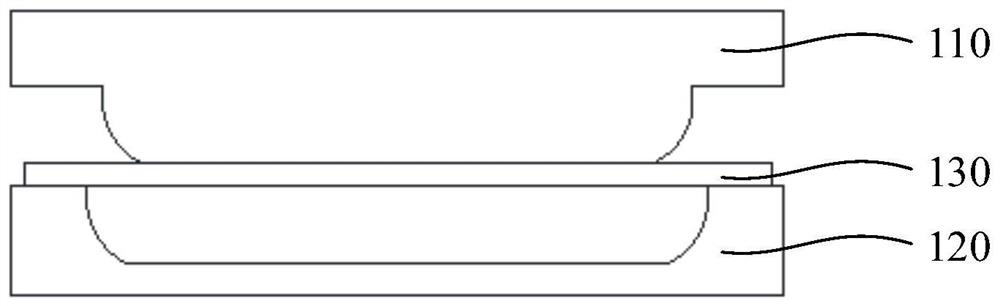

[0022] Specifically, the method for preparing the shell includes the following steps S110-S120:

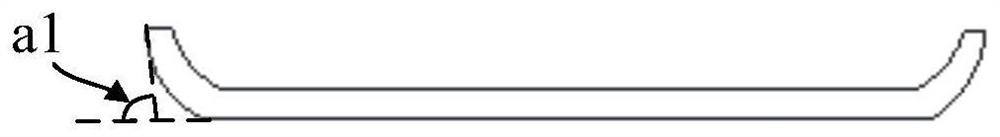

[0023] S110, placing the ceramic plate in a hot-bending mold, and performing pre-bending at 1000°C-1200°C.

[0024] The study found that if the pre-bending temperature is too low, the bending angle of the shell will be affected to affect the three-dimensional effect of the shell; if the pre-bendin...

Embodiment 1~14

[0065] The shells of Examples 1-14 were prepared according to the parameters in Table 1 and Table 2. Specifically, the preparation process of the shell is as follows:

[0066] (1) Mixing zirconia ceramic powder with organic components and molding to obtain a flat green body; degreasing the flat green body, and then sintering at T1°C for t1h to obtain a flat flat fired body with a thickness of D1mm; The flat-shaped sintered blank is subjected to flat grinding and rough polishing in sequence to obtain a ceramic plate with a thickness of D2mm. Among them, the thickness processing amount of flat grinding is 0.05mm (ie: reduce the thickness by 0.05mm), and the thickness processing amount of rough polishing is 0.05mm (ie: reduce the thickness by 0.05mm).

[0067] (2) Place the ceramic plate in the hot bending mold, raise the temperature to T2°C at a rate of V1°C / min, and apply a pre-bending pressure of P1N to the ceramic plate at T2°C to pre-bend the ceramic plate for t2h to obtain...

Embodiment 15

[0076] The preparation process of the shell of this embodiment is substantially the same as that of Embodiment 5, except that in step (4), the bent ceramic plate is directly cooled with the furnace to obtain a cooled ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com