Housing and preparation method and terminal thereof

A technology for a shell and a primer layer, which is applied to devices for coating liquid on surfaces, metal material coating processes, coatings, etc., can solve the problems of heavy weight, high cost of middle frame or cover plate, and low processing cost. , to achieve the effect of low cost, combined with high reliability and high anti-drop performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Correspondingly, as Image 6 and Figure 7 As shown, the embodiment of the present invention also provides a preparation method of the above-mentioned shell, comprising the following steps:

[0063] S101 , providing a casing base material 111 , and the casing base material 111 includes metal and / or plastic;

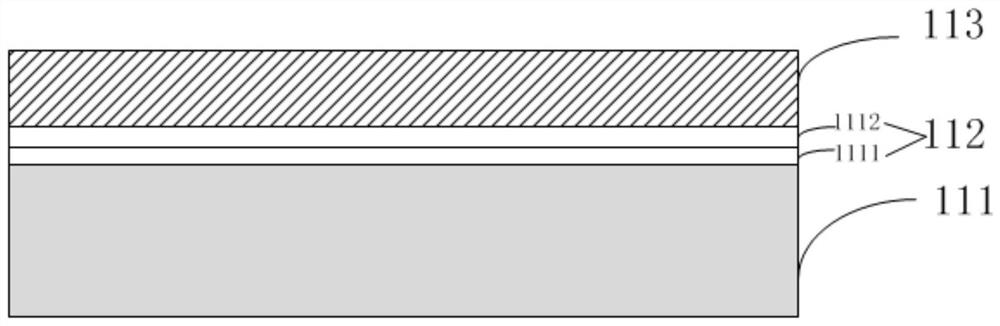

[0064] S102, preparing a first primer layer 1111 on the shell substrate 111, where the first primer layer 1111 includes a first thermosetting resin;

[0065] S103, prepare a second primer layer 1112 on the first primer layer 1111, the second primer layer 1112 includes a second thermosetting resin and inorganic ceramic powder; the heat resistance temperature of the first thermosetting resin and the second thermosetting resin are both greater than or equal to 200℃;

[0066] S104 , using a thermal spraying process to prepare a ceramic coating 113 on the second primer layer 1112 to obtain a shell.

[0067] In some embodiments of the present invention, the first pri...

Embodiment 1

[0090] A preparation method of a mobile phone middle frame with ceramic appearance, comprising:

[0091] (1) The aluminum alloy mobile phone middle frame is processed and formed by the full CNC solution;

[0092] (2) At room temperature, spray the mixture of methoxysilane and isopropanol on the appearance surface of the aluminum alloy middle frame, and the thickness is controlled at 1-2 μm; The volatilization of the solvent causes a polycondensation reaction between methoxysilane and water molecules in the air, and finally hardens to form a polymethyl silicone resin to obtain the first primer layer;

[0093] (3) At room temperature, the bisphenol A epoxy resin and Al 2 O 3 The mixture of particles (mass ratio 1:4) is sprayed on the first primer layer, the thickness is controlled at 30-50 μm, and the second primer layer is obtained after standing and curing; wherein, Al 2 O 3 The particle size is controlled in the range of 20-30μm;

[0094] (4) Preparation of Al on the sec...

Embodiment 2

[0097] A preparation method of a mobile phone middle frame with ceramic appearance, comprising:

[0098] (1) The aluminum alloy mobile phone middle frame is processed and formed by the full CNC solution;

[0099] (2) At room temperature, spray the mixture of ethoxysilane and isopropanol on the appearance surface of the aluminum alloy middle frame, and the thickness is controlled at 1-2 μm; The volatilization of the solvent, the polycondensation reaction of ethoxysilane and water molecules in the air occurs, and finally hardened to form polyethyl silicone resin, and the first primer layer is obtained;

[0100] (3) under normal temperature, will contain diaminodiphenylmethane tetraglycidylamine and Al 2 O 3 The mixture of particles (mass ratio 1:2) is sprayed on the first primer layer, the thickness is controlled at 40-60 μm, and the second primer layer is obtained after standing and curing; wherein, Al 2 O 3 The particle size is controlled in the range of 10-20μm;

[0101]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com