Assembled high-altitude hoisting platform

A hoisting platform and assembled technology, applied in the direction of hoisting device, portable lifting device, etc., can solve the problems of inability to adjust the height of the hanger, large terrain restrictions, high engineering cost, and achieve easy transfer operation, low cost, and convenient operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

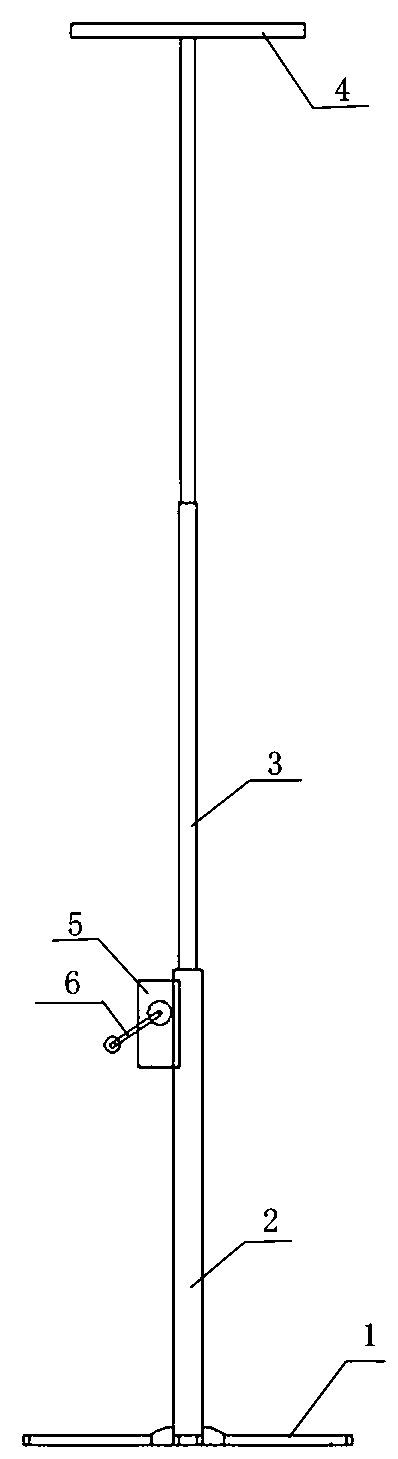

[0047] as attached Figure 1-2shown;

[0048] An assembled high-altitude hoisting platform, comprising a triangular support 1, a fixed support square rod 2 fixedly connected to the triangular support 1, a telescopic support rod 3 fixedly connected to the fixed support square rod 2, and fixedly arranged on the top of the telescopic support rod 3 The top platform plate 4 and the chain-rewinding mechanism 5 installed on the side of the fixed support square bar 2;

[0049] The chain-reversing mechanism 5 is used to lift the maintenance tool and move it to the top platform plate 4;

[0050] The chain rewinding mechanism 5 is connected with a chain rewinding handle 6 for operating the chain rewinding.

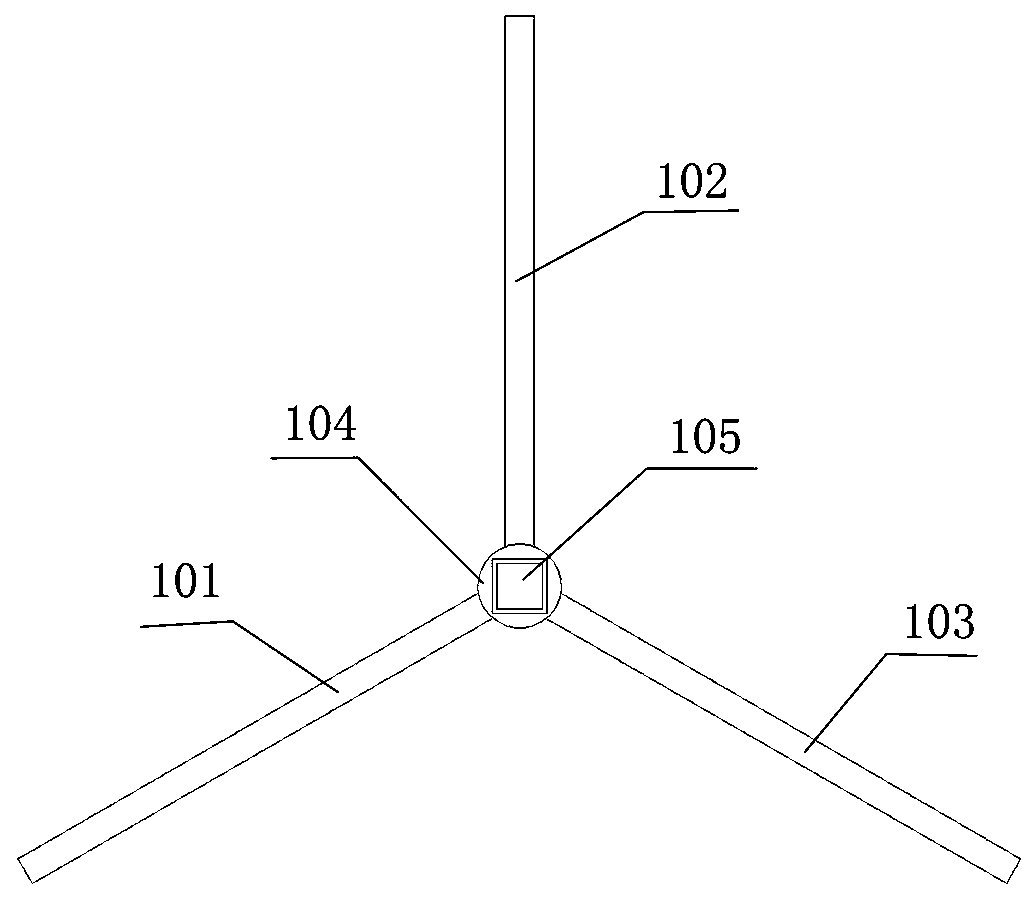

[0051] As a further improvement of the present invention, the triangular bracket 1 includes a central connection block 104, a first support rod 101, a second support rod 102, and a third support rod 103 fixedly connected to the sides of the central connection block, and a connectin...

Embodiment 2

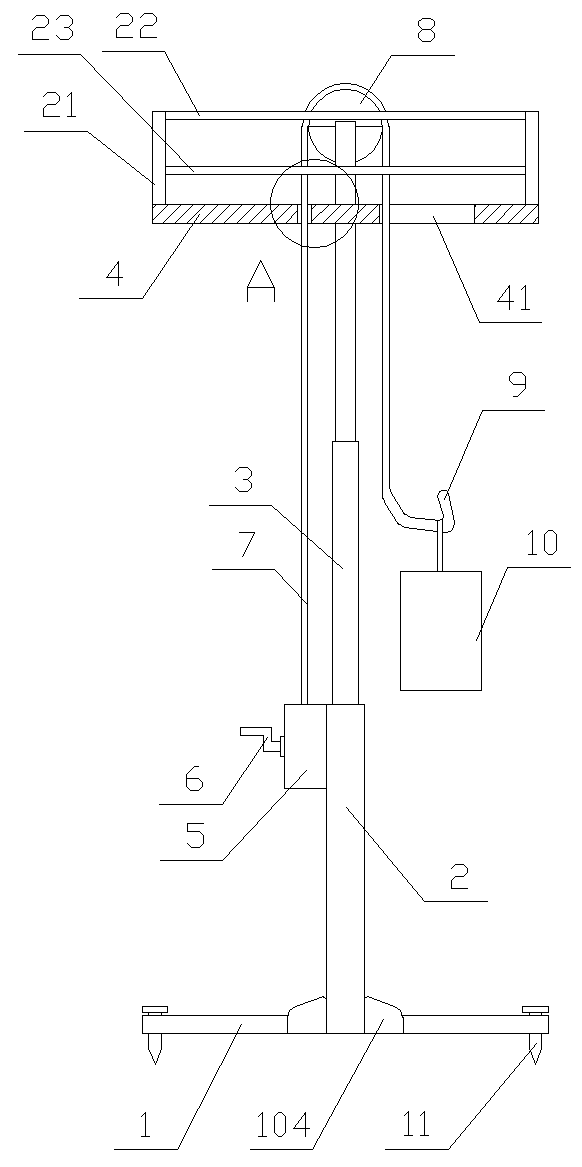

[0059] as attached Figure 3-5 shown;

[0060] An assembled high-altitude hoisting platform, comprising a triangular support 1, a fixed support square rod 2 fixedly connected to the triangular support 1, a telescopic support rod 3 fixedly connected to the fixed support square rod 2, and fixedly arranged on the top of the telescopic support rod 3 The top platform plate 4 and the chain-rewinding mechanism 5 installed on the side of the fixed support square bar 2;

[0061] The chain-reversing mechanism 5 is used to lift the maintenance tool and move it to the top platform plate 4;

[0062] The chain rewinding mechanism 5 is connected with a chain rewinding handle 6 for operating the chain rewinding.

[0063] As a further improvement of the present invention, the triangular bracket 1 includes a central connection block 104, a first support rod 101, a second support rod 102, and a third support rod 103 fixedly connected to the sides of the central connection block, and a connecti...

Embodiment 3

[0074] as attached Figure 3-6 shown;

[0075] An assembled high-altitude hoisting platform, comprising a triangular support 1, a fixed support square rod 2 fixedly connected to the triangular support 1, a telescopic support rod 3 fixedly connected to the fixed support square rod 2, and fixedly arranged on the top of the telescopic support rod 3 The top platform plate 4 and the chain-rewinding mechanism 5 installed on the side of the fixed support square bar 2;

[0076] The chain-reversing mechanism 5 is used to lift the maintenance tool and move it to the top platform plate 4;

[0077] The chain rewinding mechanism 5 is connected with a chain rewinding handle 6 for operating the chain rewinding.

[0078] As a further improvement of the present invention, the triangular bracket 1 includes a central connection block 104, a first support rod 101, a second support rod 102, and a third support rod 103 fixedly connected to the sides of the central connection block, and a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com