Breathable slow rebound polyurethane foam and its preparation method and application

A foamed plastic and polyurethane technology, applied in the field of polyurethane foamed plastic and its preparation, can solve the problems of poor slow rebound effect and low air permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. In container A, add polyether polyol A: 20 parts, polyether polyol B: 40 parts, polyether polyol C: 40 parts, water: 2 parts, A-33: 0.5 parts part, T-9: 0.1 part, L-618: 1 part, stir evenly, the stirring speed is 2500rpm, and the stirring temperature is 25°C; the hydroxyl value of polyether polyol A is 112gKOH / g, the functionality is 3, and the ring Ethylene oxide accounts for 60% by weight of the molecular weight of polyether polyol A; the hydroxyl value of polyether polyol B is 180mgKOH / g, and the functionality is 3, and ethylene oxide accounts for the molecular weight of polyether polyol B The weight percent content of polyether polyol C is 85%; the hydroxyl value of polyether polyol C is 41 mgKOH, and the functionality is 3;

[0026] 2. Add 60 parts by weight of toluene diisocyanate into container A, stir for 4-6 seconds to obtain material I, the stirring speed is 3000rpm, and the stirring temperature is 25°C;

[0027] 3. Quickly pour the material Ⅰ into a foami...

Embodiment 2 to Embodiment 5

[0029] Examples 2 to 5 were carried out according to the steps of Example 1. The only difference was the type of raw materials, the ratio of raw materials, the reaction time and the temperature. See Table 3 for details. The prepared breathable slow-rebound polyurethane foam The product quality inspection data are shown in Table 5.

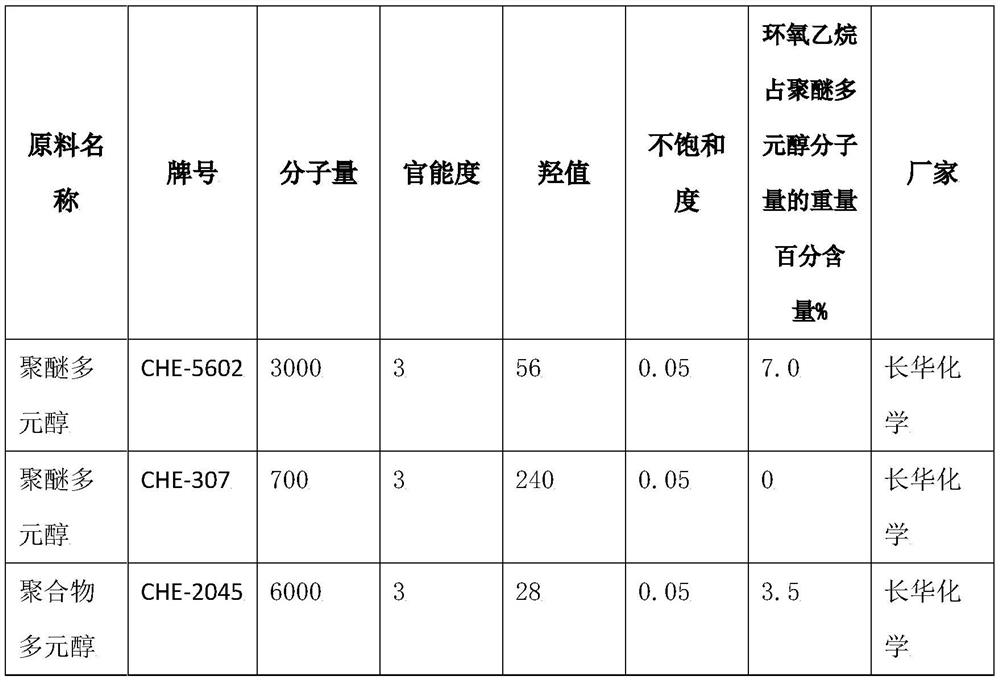

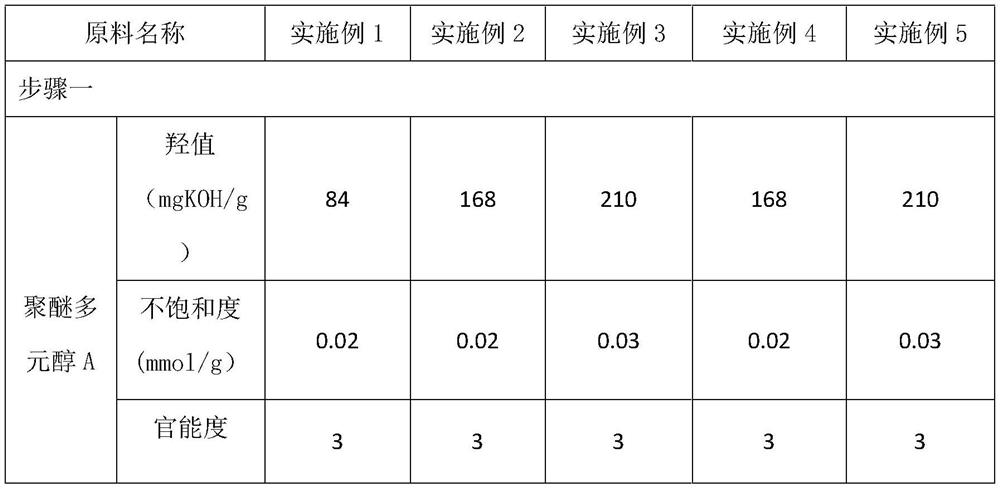

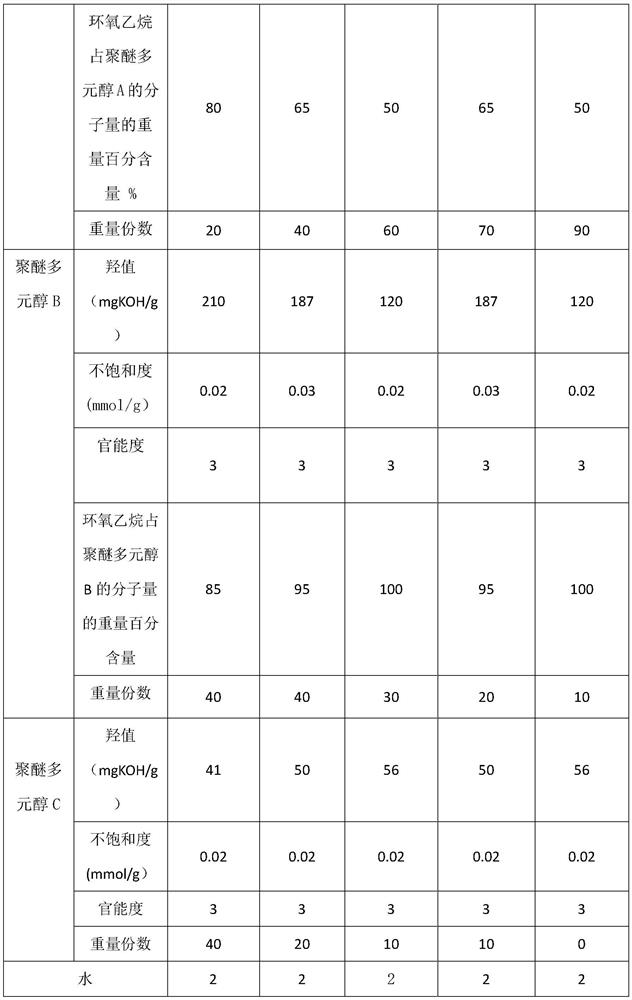

[0030] The parts by weight of raw materials of each component in table 3 embodiment 1 to embodiment 5

[0031]

[0032]

[0033]

Embodiment 6 to Embodiment 8 and comparative example 1 to 3

[0035] Examples 6 to 8 and Comparative Examples 1 to 3 were carried out according to the steps of Example 1. The only difference was the type of raw materials, the ratio of raw materials, the reaction time and the temperature. See Table 4 for details. The prepared breathable The product quality inspection data of slow rebound polyurethane foam are shown in Table 5.

[0036] The parts by weight of raw materials of each component in table 4 embodiment 6 to embodiment 8 and comparative examples 1 to 3

[0037]

[0038]

[0039]

[0040] The quality inspection data of the air-permeable slow-rebound polyurethane foam plastics that table 5 embodiment 1 to 8 and comparative example 1 to 3 prepare

[0041]

[0042] As can be seen from Examples 1 to 8, the air permeability of the polyurethane foam of the present invention is as high as 332 L / min, indicating that the air permeability of the polyurethane foam is good; the depression recovery time of the present invention is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com