An oil drilling rig data acquisition device

A technology for data acquisition and oil drilling, which is applied to drilling equipment, earth-moving drilling, and automatic control systems for drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

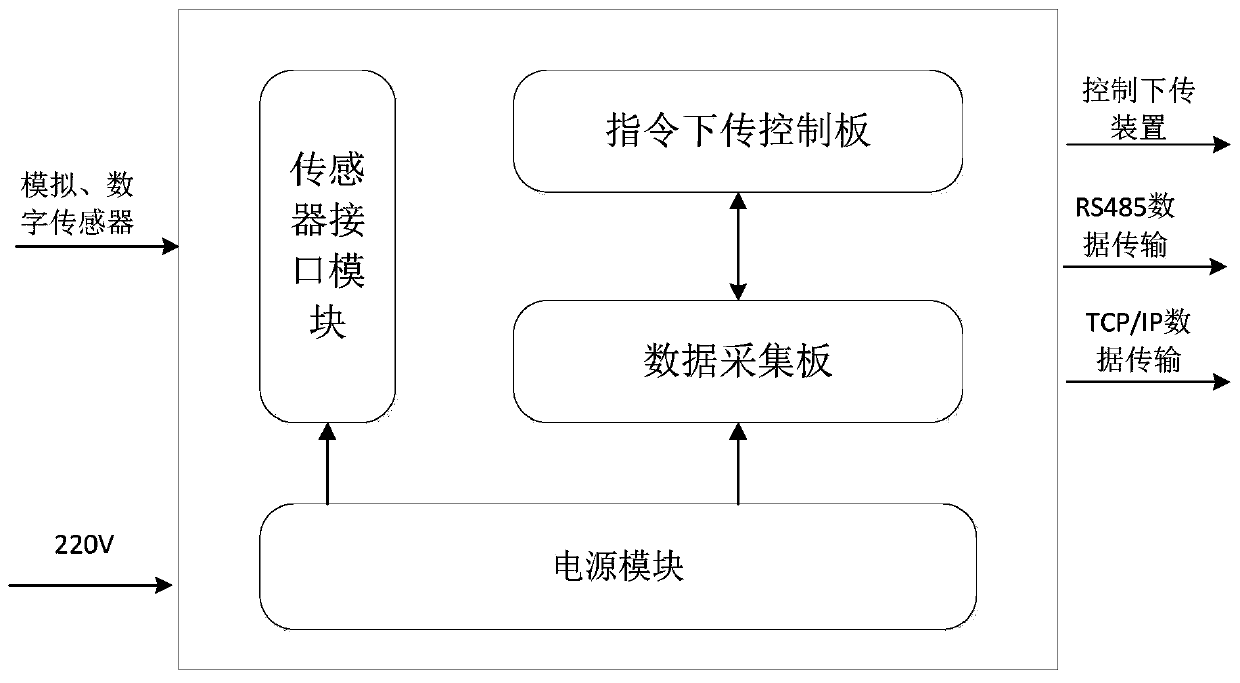

[0035] Such as figure 1 shows the main modules of the acquisition device, combined with figure 1 As shown, a data acquisition device for an oil drilling rig can include a device box, and the inside of the device box is provided with an explosion-proof power supply, a sensor interface module, a data acquisition circuit board, and a command downlink control circuit board; the explosion-proof The power supply is used to convert the 220v AC power supply to the DC power supply required by the sensor and the circuit board; the sensor interface module is used to supply power to the sensor and the photoelectric isolation of the sensor signal; the data acquisition circuit board includes a power supply module, a temperature test module, Data acquisition module, data storage module, data transmission module, programmable control module; the power module is used to convert the power output by the explosion-proof power supply into the power required by the circuit board; the temperature te...

Embodiment 2

[0040] In the drilling floor data acquisition device provided by the present invention, the data acquisition circuit board can also be composed of a power supply module, a sensor signal conditioning module, a temperature test module, a data acquisition module, a programmable control module, a data storage module, and a data transmission module.

[0041] Power module:

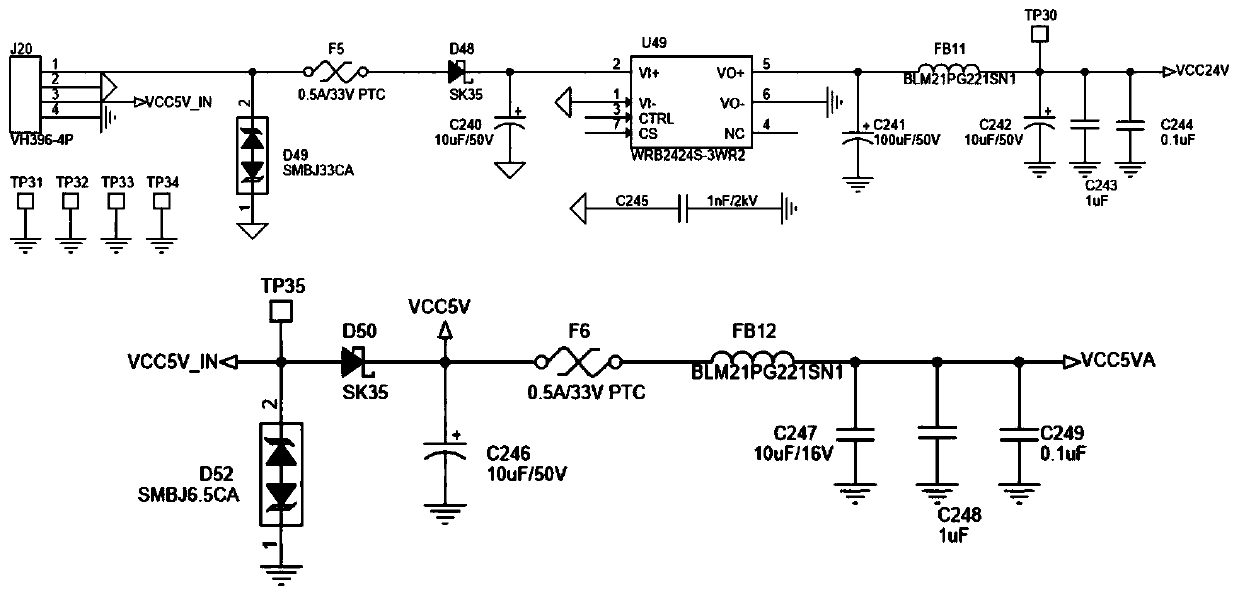

[0042] Such as figure 2 As shown, the data acquisition circuit board needs 24V, 5V, 3.3V power supply. The 24V power supply module adopts WRB2424S-3WR2, and the input terminal VI+ is 24V power supply output by AC-DC of explosion-proof power supply, which passes through SMBJ33CA transient suppression diode, is protected by series PTC self-recovery fuse, and then enters the power supply module after being filtered by capacitor C240. The output terminal VO+ is filtered by the filter circuit composed of devices C241, BLM21PG221SN1, C242, C243, and C244, and then outputs 24V. The 24V output by the explosion-proof p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com