scroll compressor

A scroll compressor and scroll technology, applied in the field of compressors, can solve problems such as the rigidity of the scroll part without specific consideration, and achieve the advantages of preventing deformation or rupture, friction loss or wear improvement, and improving efficiency and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

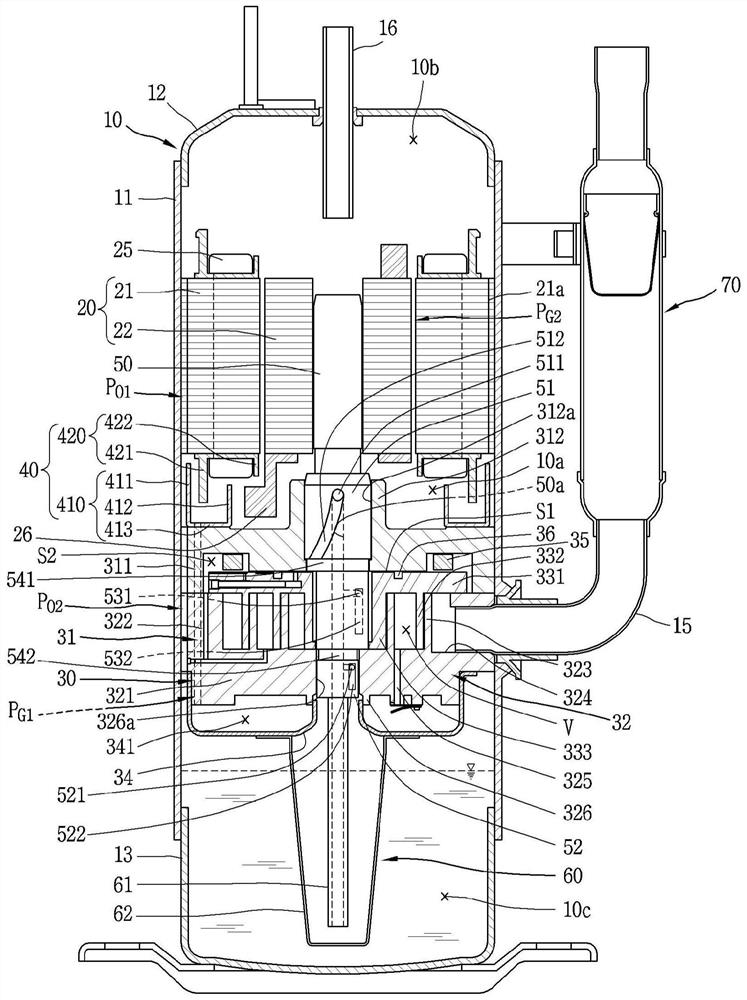

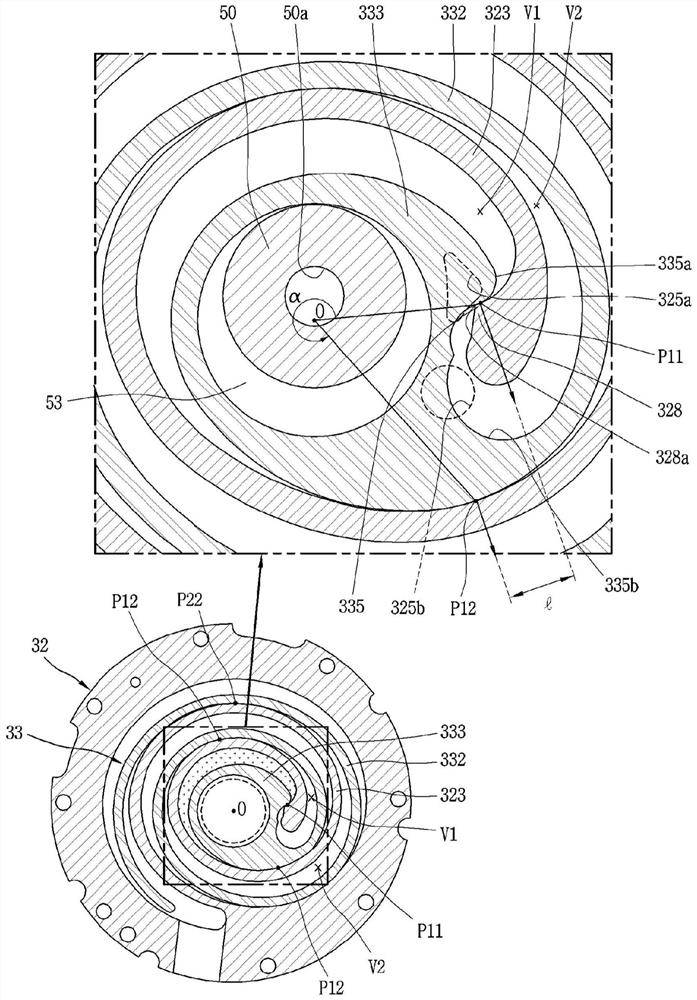

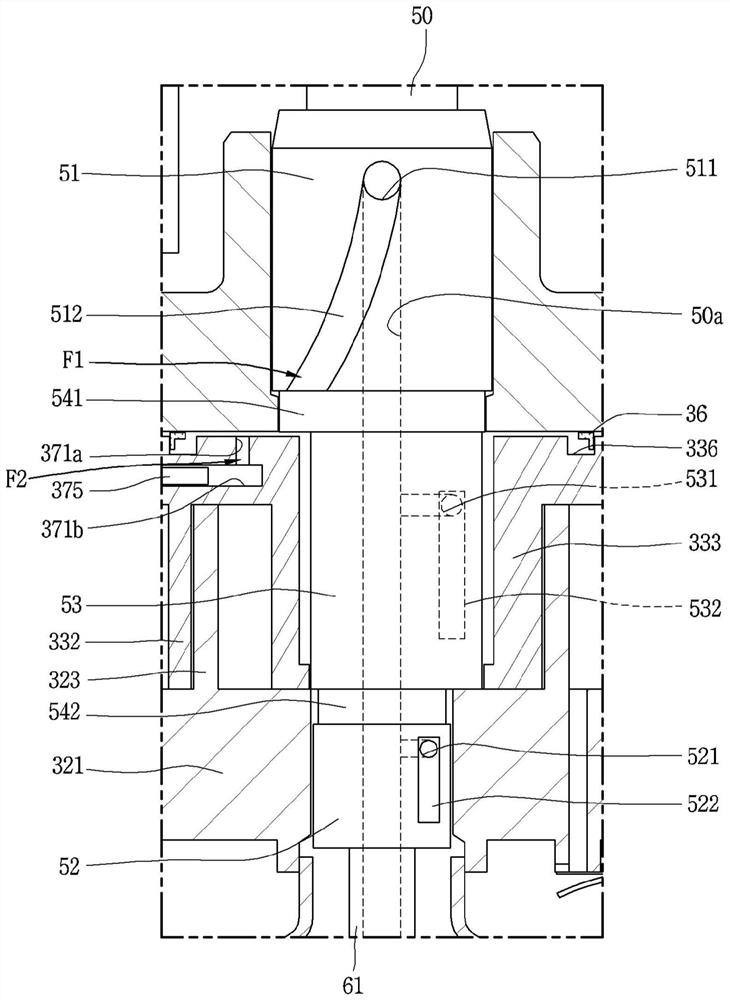

[0047] Hereinafter, the scroll compressor of the present invention will be described in detail with reference to an embodiment shown in the accompanying drawings. However, for convenience of explanation, a typical example of a lower compression type scroll compressor in which the rotating shaft and the orbiting wrap overlap on the same plane in which the compression portion is located below the transmission portion will be described below. This type of scroll compressor is known to be suitable for refrigeration cycles under high temperature and high compression ratio conditions.

[0048] figure 1 It is a longitudinal sectional view showing the lower compression type scroll compressor of the present invention. figure 2 yes means figure 1 Transverse sectional view of the compression section in . image 3 is to illustrate figure 1 The front view of a part of the rotating shaft is shown as the sliding part in the figure. Figure 4 is to illustrate figure 1 A longitudinal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com