Plant illumination area light source with high light mixing uniformity

A plant lighting and uniformity technology, which is applied in the direction of electroluminescent light source, light source, electric light source, etc., can solve the problems of unscientific design of plant growth lights, and achieve the effect of reducing the density of lights, increasing the degree of coupling, and stabilizing light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

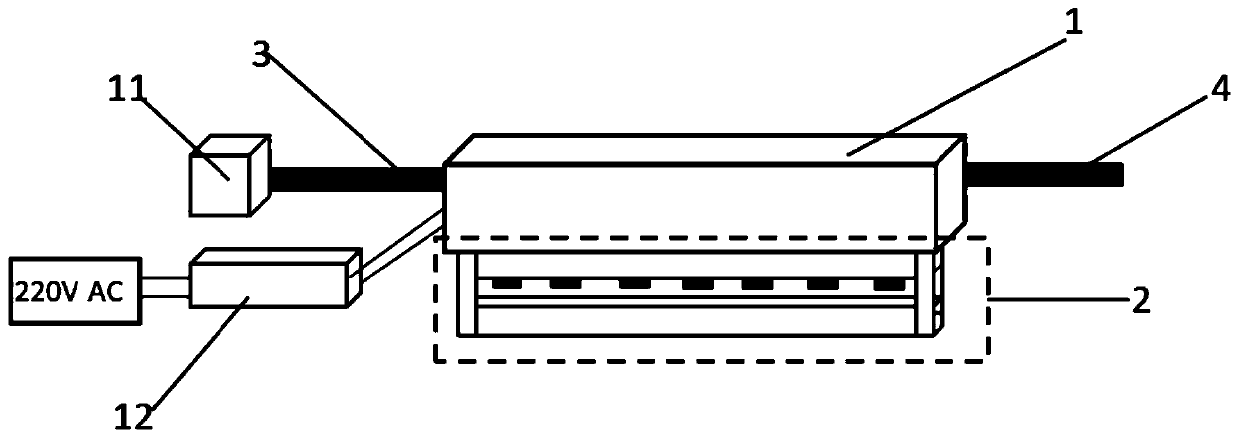

[0027] Such as figure 1 As shown, a plant lighting surface light source with high light mixing uniformity, the lamp is divided into three parts: a radiator part 1 with high heat dissipation effect, a light source module 2 and a dual modulation technology driving peripheral circuit 12; the light source module 2 is arranged in an array The cloth is regularly arranged at equal intervals on the radiator part with high heat dissipation effect, figure 1 The middle and outer pump body 11 is used to pump the unused water for seedling irrigation into the heat dissipation cavity of the radiator part 1; the dual modulation technology drives the peripheral circuit 12 for driving and dimming the LED lamp beads.

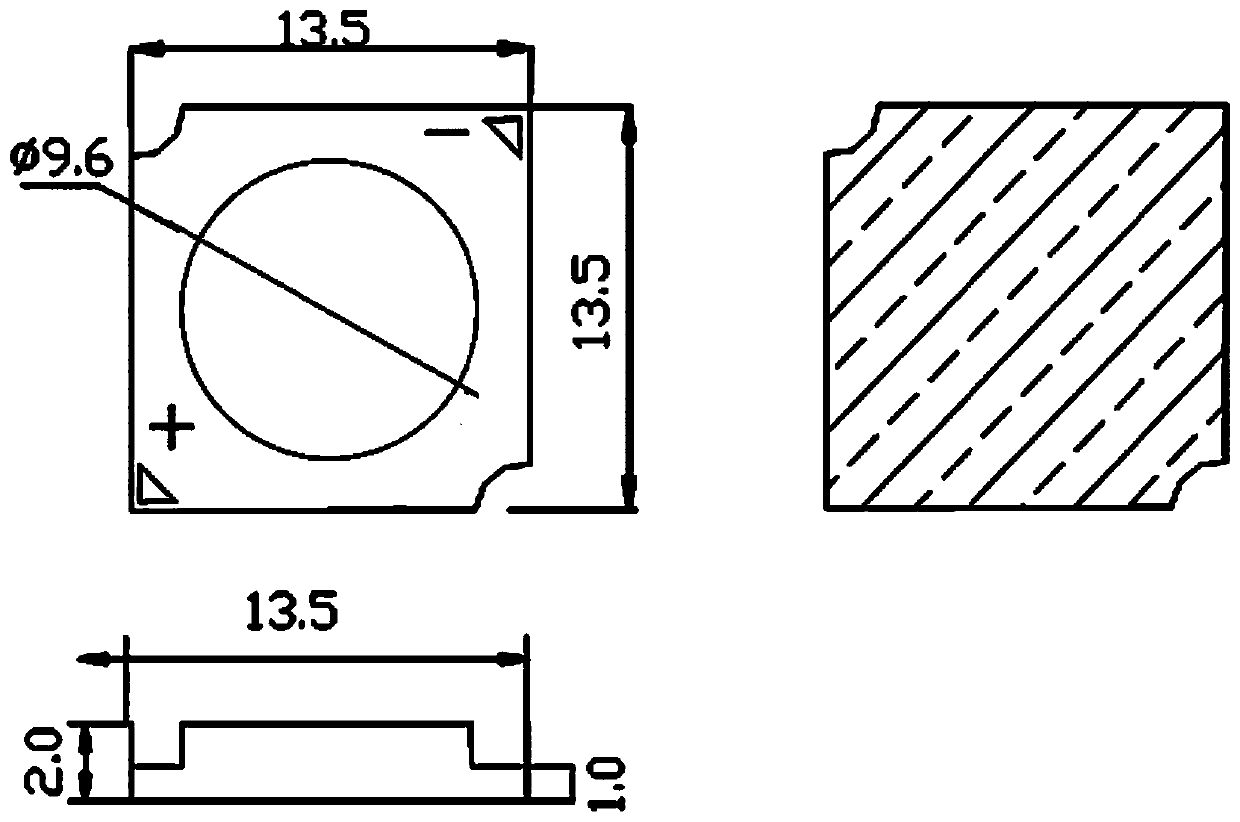

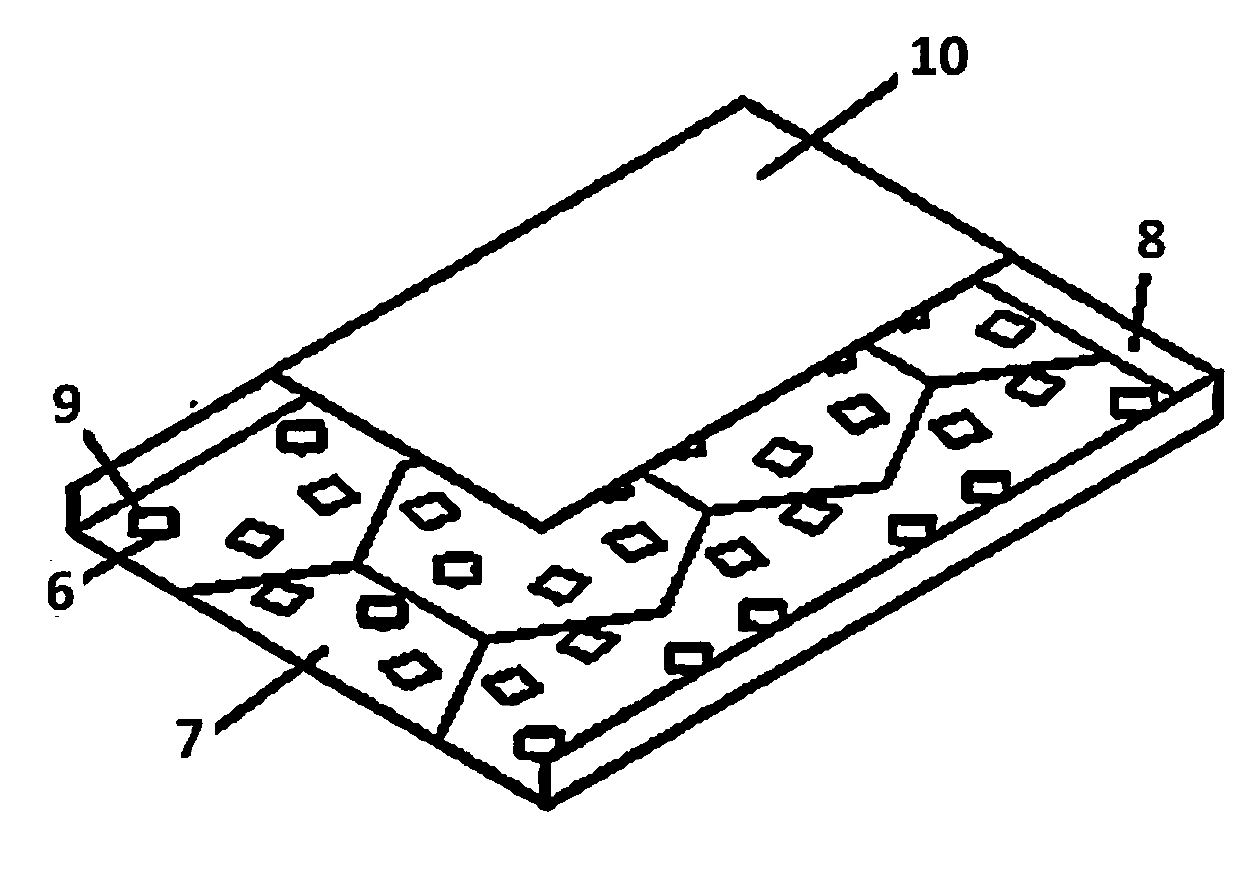

[0028] Such as image 3 As shown, the light source module includes an LED lamp bead 6, a diffuse reflection base plate 7, a peripheral frame 8, a light mixing element 9 made of PMMA and an exit panel 10 mounted on the LED lamp bead; the side of the light mixing element 9 is a ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com