Manufacture method of wheat germ cereal bar

A technology of grain and wheat germ, which is applied in the field of preparation of wheat germ cereal bars, can solve the problem that wheat germ resources have not been fully rationally and effectively utilized, and achieve the effect of increasing protein content and nutritional value, and enriching varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a preparation method of wheat germ cereal bar, comprising the following steps:

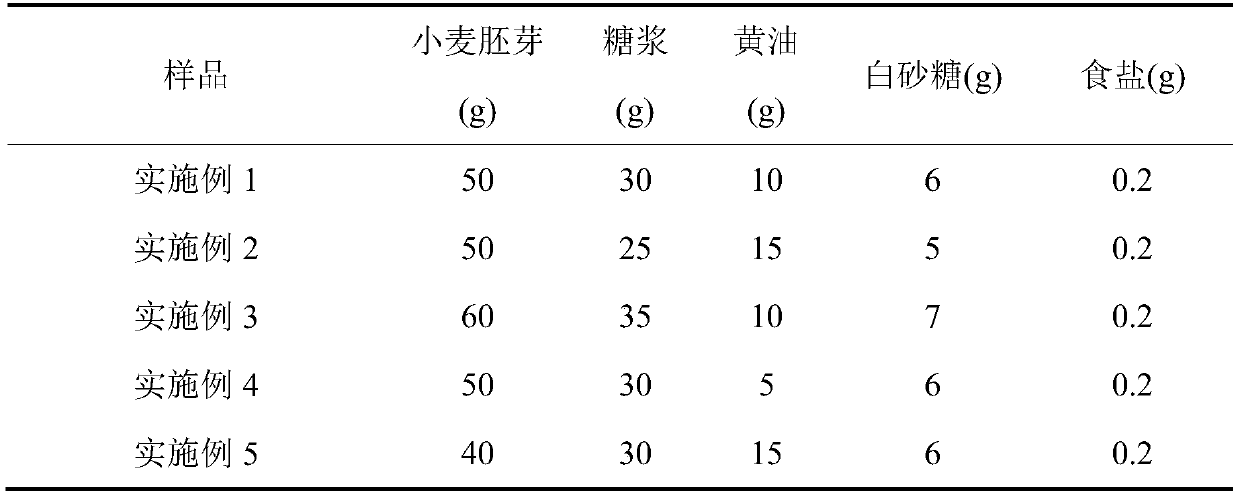

[0022] 1) 40-60 parts of wheat germ, 40-60 parts of oats, 5-15 parts of butter, 25-35 parts of malt syrup, 5-7 parts of white sugar, and 0.2 parts of table salt.

[0023] 2) According to the proportioning in step 1), the wheat germ and oats are pretreated and stirred evenly;

[0024] 3) With the proportioning of step 1), the maltose syrup is heated in water;

[0025] 4) Add butter and salt to the syrup in step 3) to dissolve and mix evenly;

[0026] 5) quickly pour the liquid obtained in step 4) into the grain mixture obtained in step 2), and stir evenly;

[0027] 6) Put the mixture obtained in step 5) in a baking tray, squeeze it tightly to a thickness of about 2cm, and bake at 150°C for 15 minutes;

[0028] 7) Cut the sample obtained in step 6) while it is hot.

[0029] 8) Cool the wheat germ cereal bar obtained after cutting while it is hot at room temperature,...

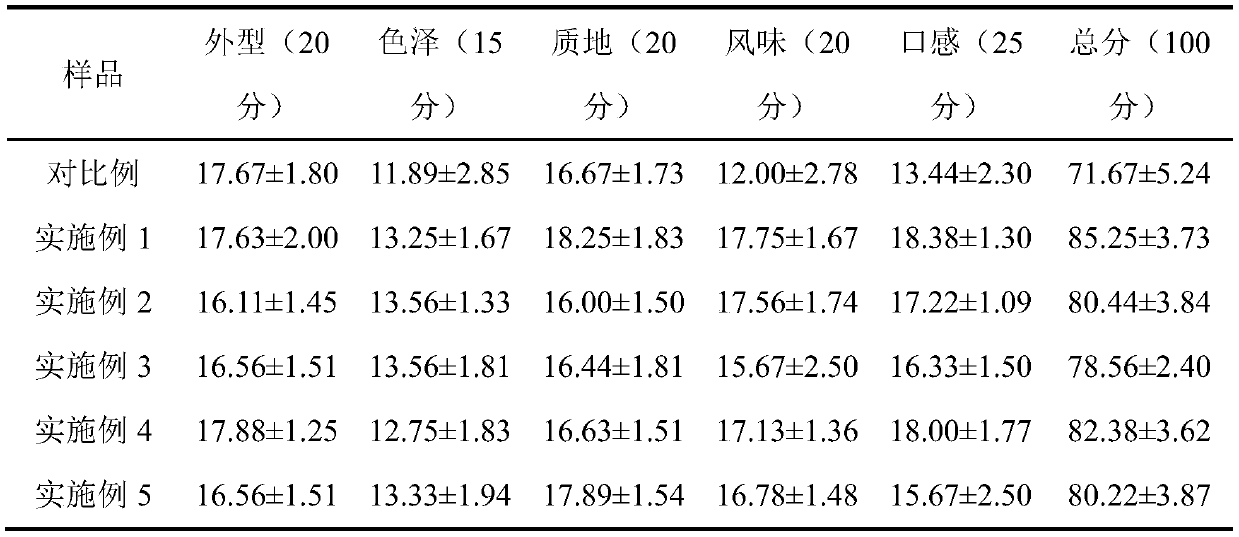

Embodiment 1-5

[0032] 1) Each raw material is prepared according to the mass of 1g / part, and the dosage of each raw material is shown in Table 1.

[0033] 2) Pretreat the wheat germ and oats according to the ratio described in step 1). The wheat germ pretreatment condition is microwave treatment at 700W for 2 minutes, the oat pretreatment condition is baking at 180°C for 10 minutes, and the treated grain raw materials are stirred Uniform;

[0034] 3) With the proportioning described in step 1), heating the maltose syrup with water;

[0035] 4) Add butter and salt to the syrup in step 3) to dissolve and mix evenly;

[0036] 5) Pour the liquid obtained in step 4) into the grain mixture obtained in step 2) while hot and stir evenly;

[0037] 6) Put the mixture obtained in step 5) in a baking tray, squeeze it tightly to a thickness of about 2cm, and bake at 150°C for 15 minutes;

[0038] 7) The sample obtained in step 6) is cut into cereal bars with a length of 4 cm and a width of 2 cm while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com