Dual-layer rolled lining and processing technology thereof

A processing technology, double-layer technology, applied in the direction of metal processing equipment, etc., can solve the problems of low efficiency, high cost, and inability to realize processing, so as to achieve the effect of ensuring processing accuracy, high processing accuracy and high degree of processing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

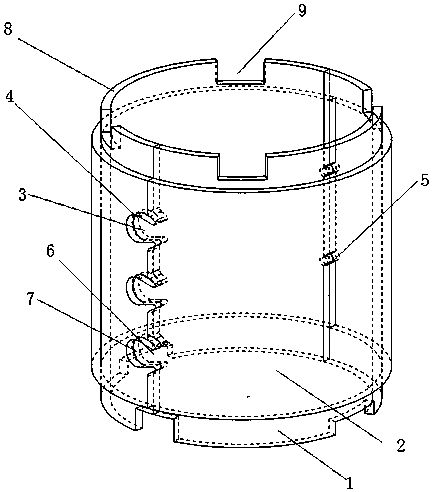

[0021] Such as figure 1 As shown, a double-layer rolled bush disclosed by the present invention includes an inner layer 1 and an outer layer 2 that are nested and riveted with each other. The opposite side is mutually riveted between the inner layer and the outer layer.

[0022] Specifically, the inner layer is formed by curling a first sheet, one end of which is provided with a first buckle 3, and the other end is correspondingly provided with a first groove 4, and the first sheet is spaced apart on the vertical center line. A plurality of riveting holes 5, the outer layer is formed by curling a second sheet, one end of which is provided with a second hasp 6, and the other end is correspondingly provided with a second groove 7, the first hasp and the second hasp The buckle is in the shape of a drop, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com