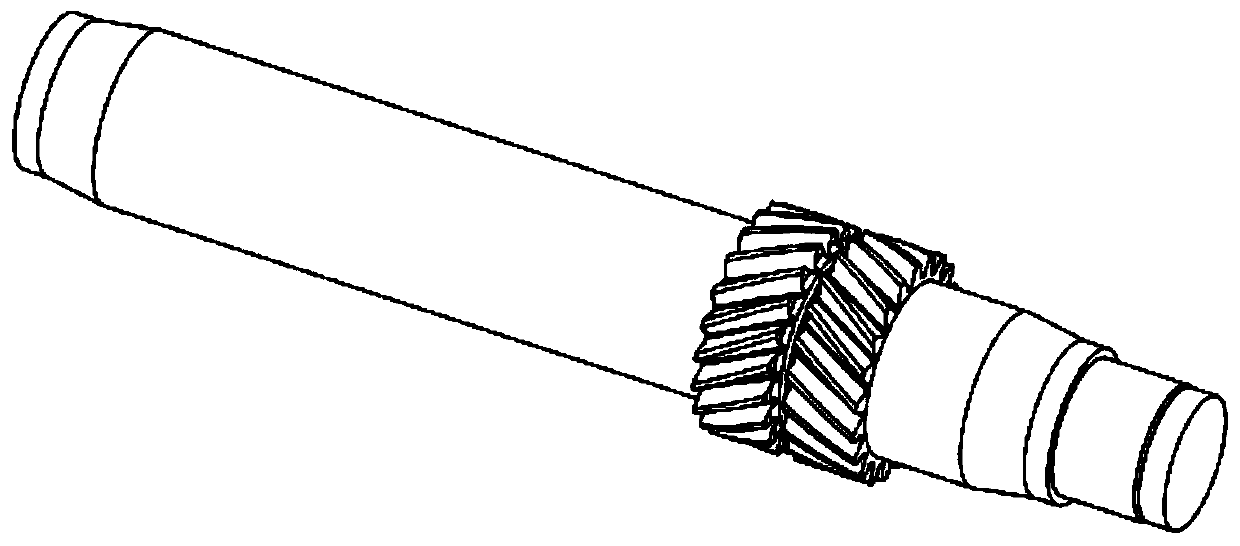

Processing tool and processing method for herringbone gear shaft of small tool withdrawal groove

A gear shaft and undercut technology, which is used in gear tooth manufacturing devices, components with teeth, metal processing equipment, etc., can solve the problems of expensive equipment, lack of purchasing power, and high cost of outsourced processing. To achieve the effect of easy operation, good use value and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

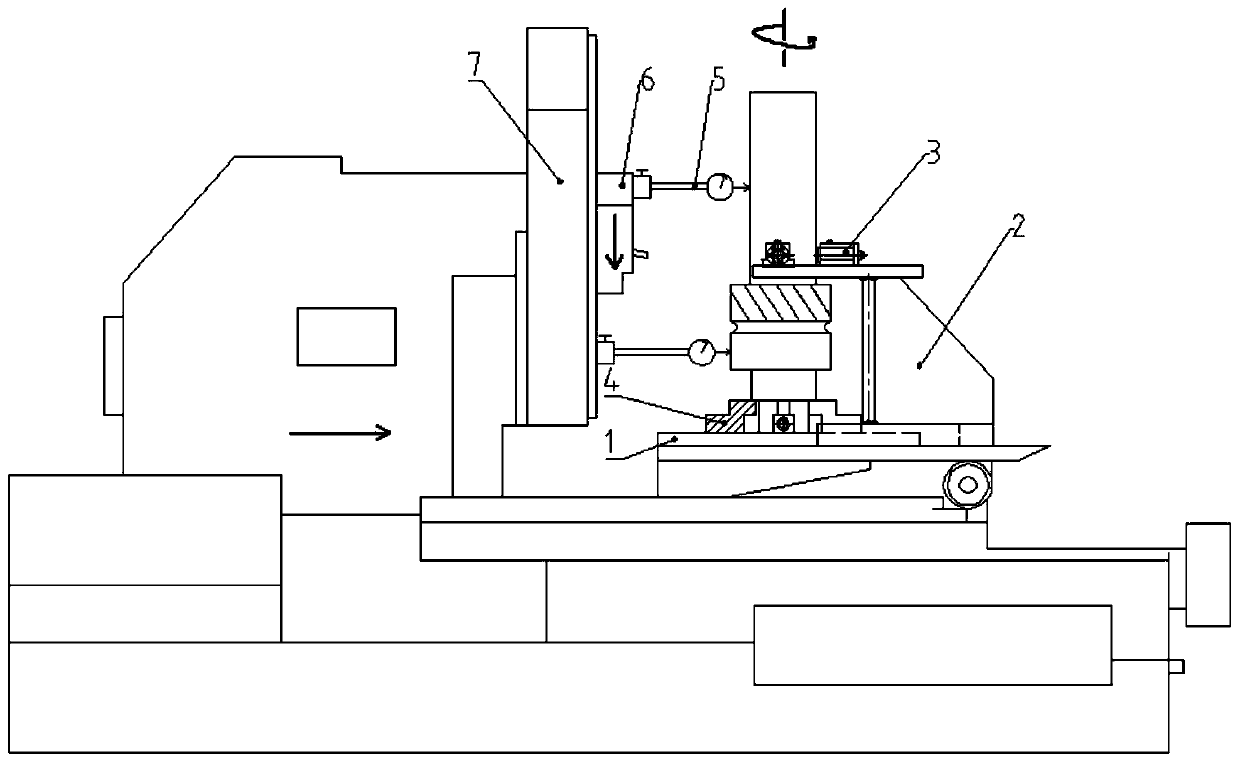

[0020] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

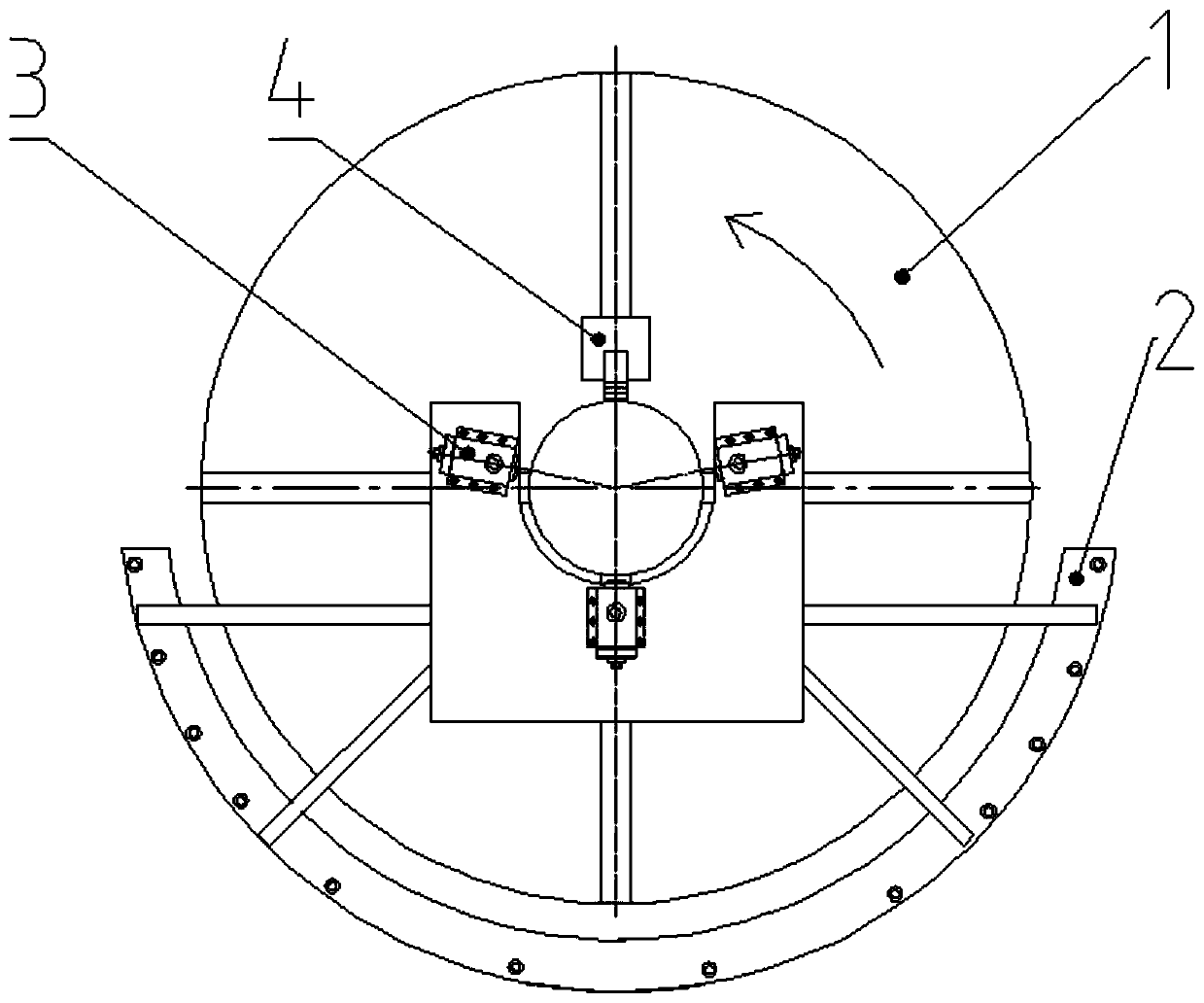

[0021] figure 2 Shown is a schematic top view of the structure of the present invention.

[0022] The invention provides a processing tool for a herringbone gear shaft with a small undercut, which includes a workbench 1, a semicircle frame 2, an adjustable thimble 3 and claws 4, and the claws 4 are evenly distributed and fixed on the workbench 1 , the semicircle frame 2 is fixed on the periphery of the workbench 1; the adjustable thimble 3 is fixed on the top surface of the semicircle frame 2 at an appropriate angle, so that the axis extension line is focused on the center of the opening arc.

[0023] Described claw 4 is vertical lathe claw.

[0024] The semicircle frame 2 adopts a welded structure, including a bottom plate and a top plate. The bottom plate is an arc-shaped plate, and the top plate is a rectangular plate with a "U-shaped" openin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap