Notch polishing device for PE water supply pipe production

A technology for water supply pipes and incisions, which is applied in the direction of grinding drive devices, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., which can solve problems such as the inability to grind the inner and outer walls of pipe fittings, and achieve the effect of improving grinding and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

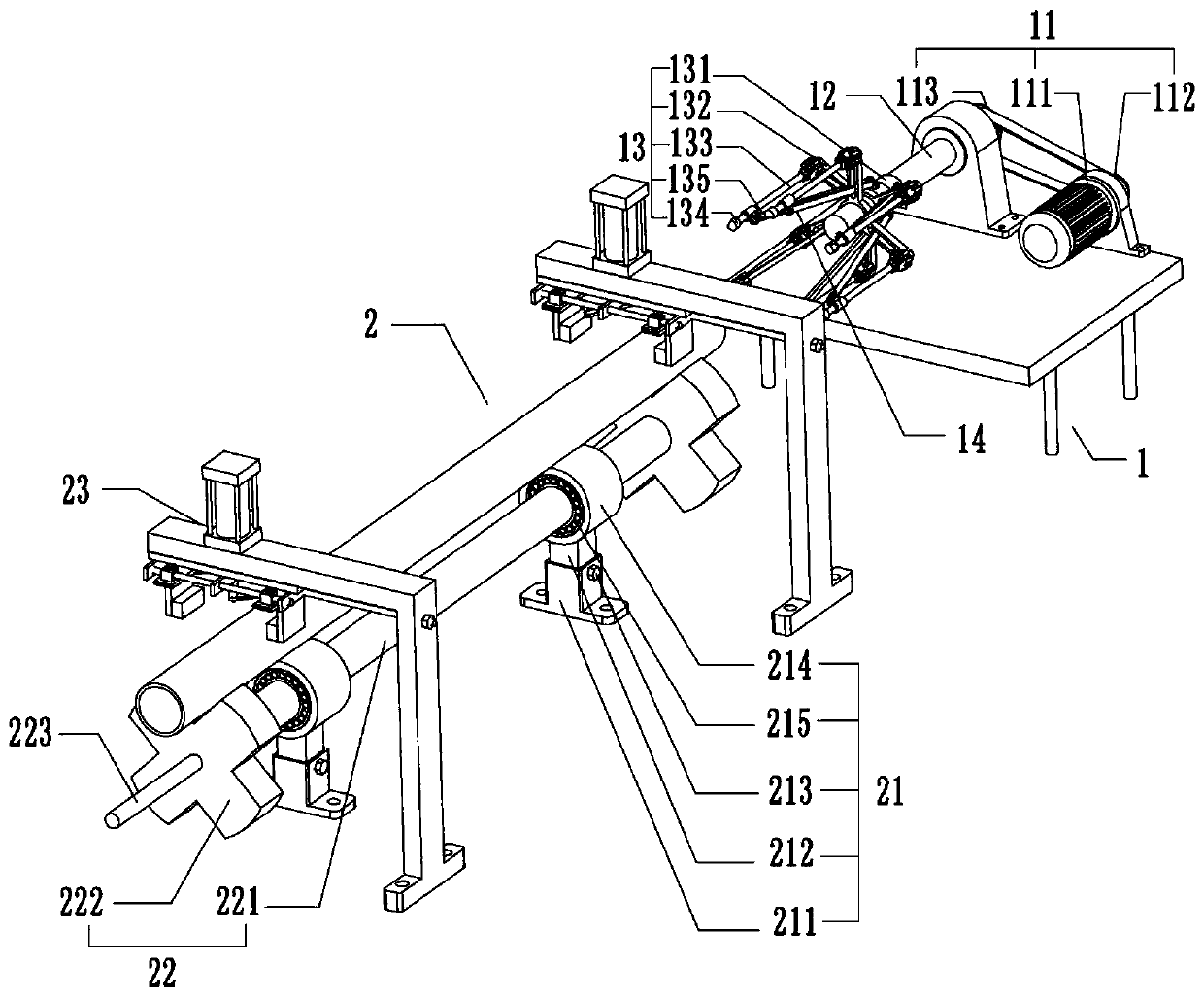

[0047] Such asfigure 1 and figure 2 As shown, a cutting grinding device for the production of PE water supply pipes includes an adjustable inner and outer wall grinding part 1 and a PE water supply pipe fixing part 2 arranged adjacently;

[0048] The adjustable inner and outer wall grinding part 1 is used for grinding pipe diameters of various specifications and the wall thickness of pipe fittings, and the adjustable inner and outer wall grinding part 1 is set to include a driving mechanism 11, a rotating spindle 12, an inner wall grinding mechanism 13 and an outer wall grinding Mechanism 14, the driving mechanism 11 is arranged on the side of the fixed part 2 of the PE water supply pipe, and the output end of the driving mechanism 11 is connected to the input end of the rotating main shaft 12, and the inner wall grinding mechanism is arranged adjacent to and staggered on the output end of the rotating main shaft 12 13 and the outer wall grinding mechanism 14, the inner wall ...

Embodiment 2

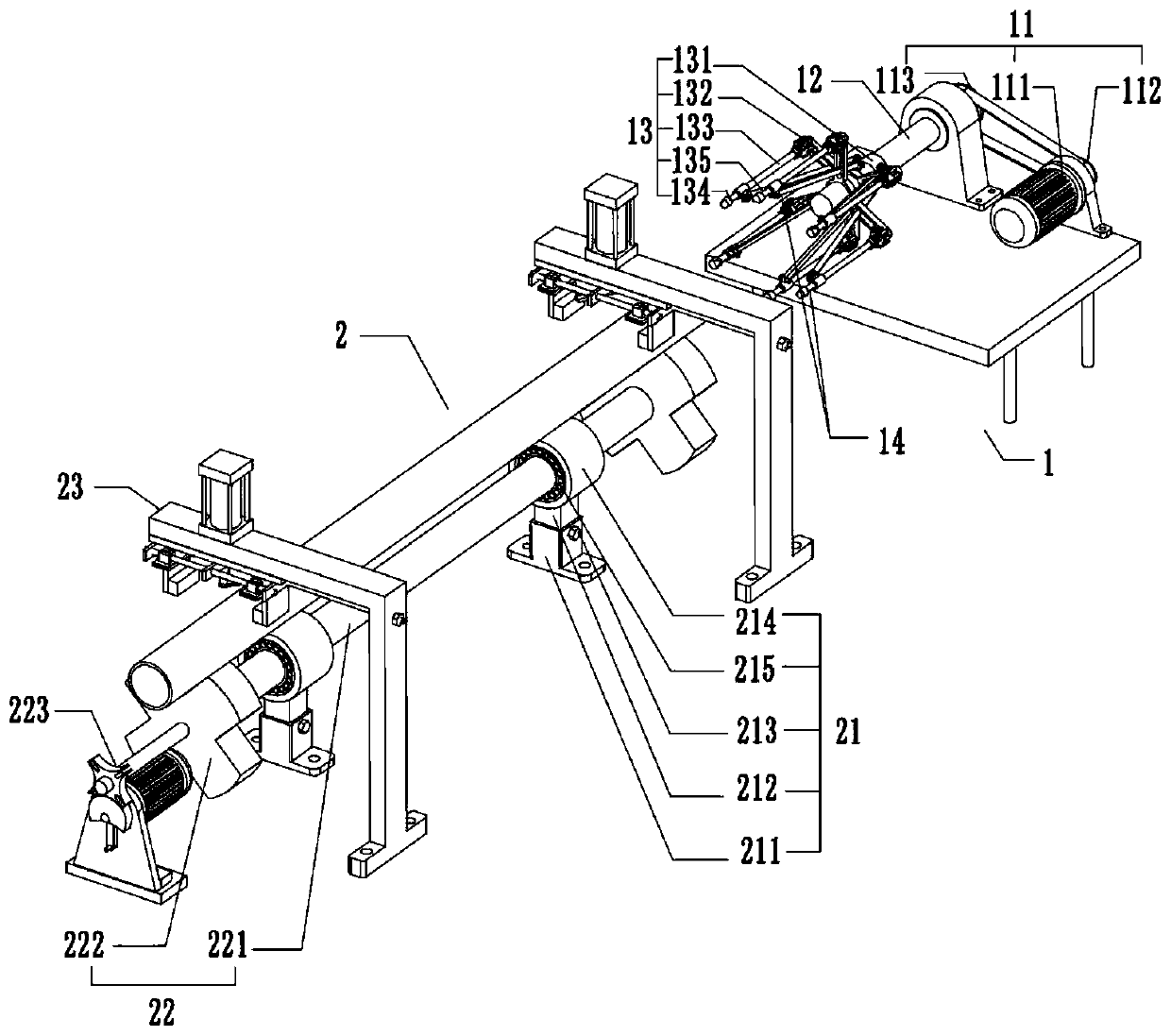

[0066] Such as image 3 As shown, the difference from Embodiment 1 is that, further, the driving body 223 can be configured to include a motor 2, a driving dial and a driven sheave, and the motor 2 is fixed laterally adjacent to the side of the height adjustment mechanism 21, and the The driving dial is fixed on the output end of the motor shaft of the second motor, and the driven sheave is fixed on the side of the multi-position support plate 222 away from the connecting rod 221 through the connecting shaft. In the radial groove of the sheave, the driven sheave is driven to rotate, and at the same time, the locking arc section on the driving dial can fit into the notch on the driven sheave, and the driven sheave is locked to drive the multiplexer. The bit support plate 222 rotates intermittently, and the driving dial is driven by the second motor to rotate, so that the dial pin and the locking arc section on the driving dial cooperate with the driven sheave to push the driven...

Embodiment 3

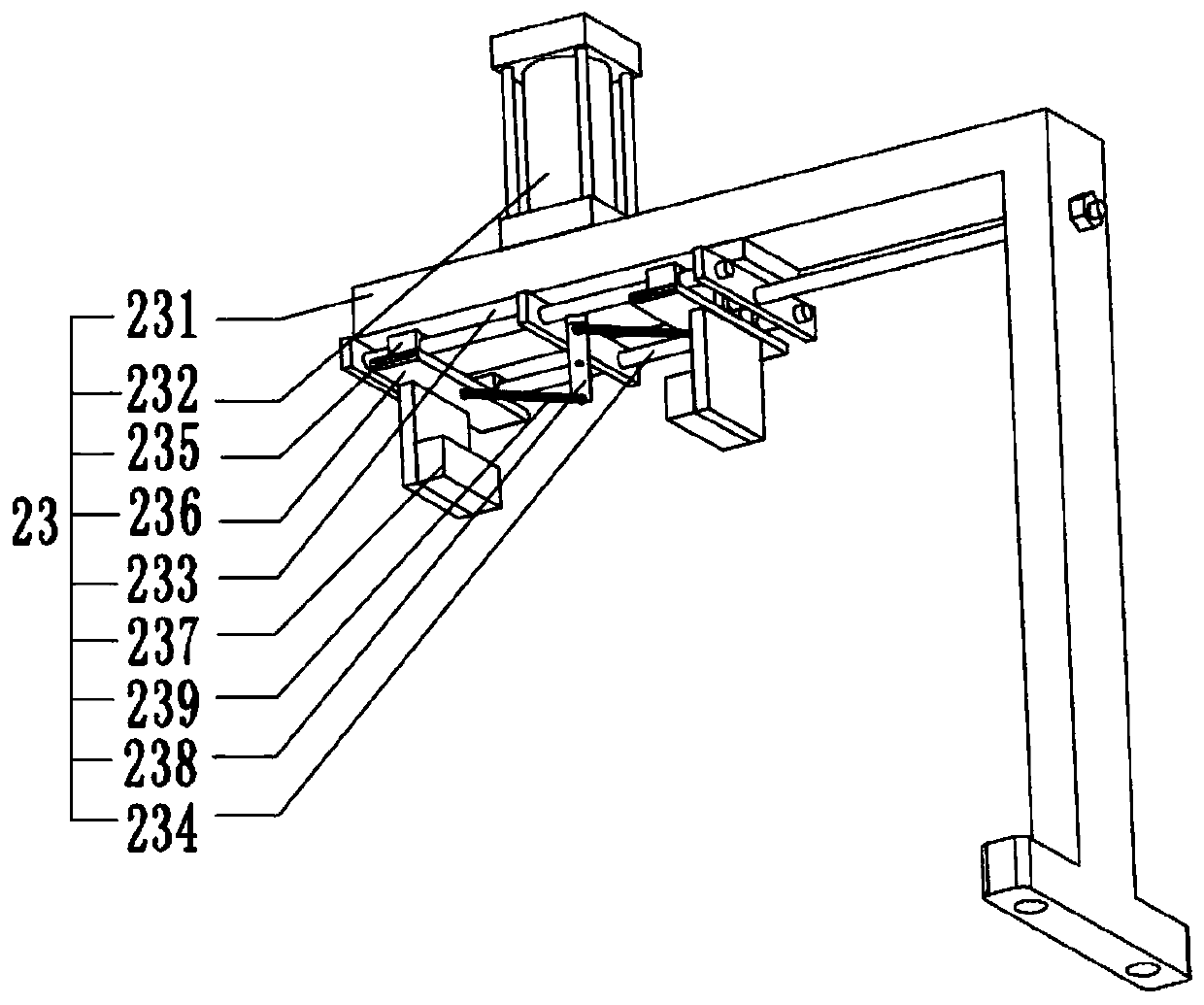

[0069] Such as Figure 4 As shown, the difference from Embodiment 1 and Embodiment 2 is that further, the drive assembly can be set as a push-pull rod and a telescopic cylinder, the beginning of the push-pull rod is fixed on the mounting plate 236, and the end of the push-pull rod is fixed to the output end of the telescopic cylinder , The telescopic cylinder is fixed on a 231 column of the mounting frame.

[0070]Specifically, the beginning end of the push-pull rod can be welded and fixed on the mounting plate 236, and the end of the push-pull rod can be fixed to the output end of the telescopic cylinder by bolts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com