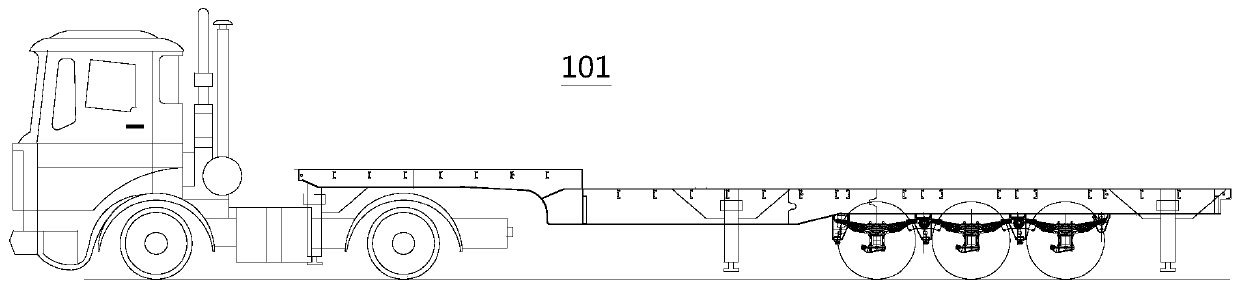

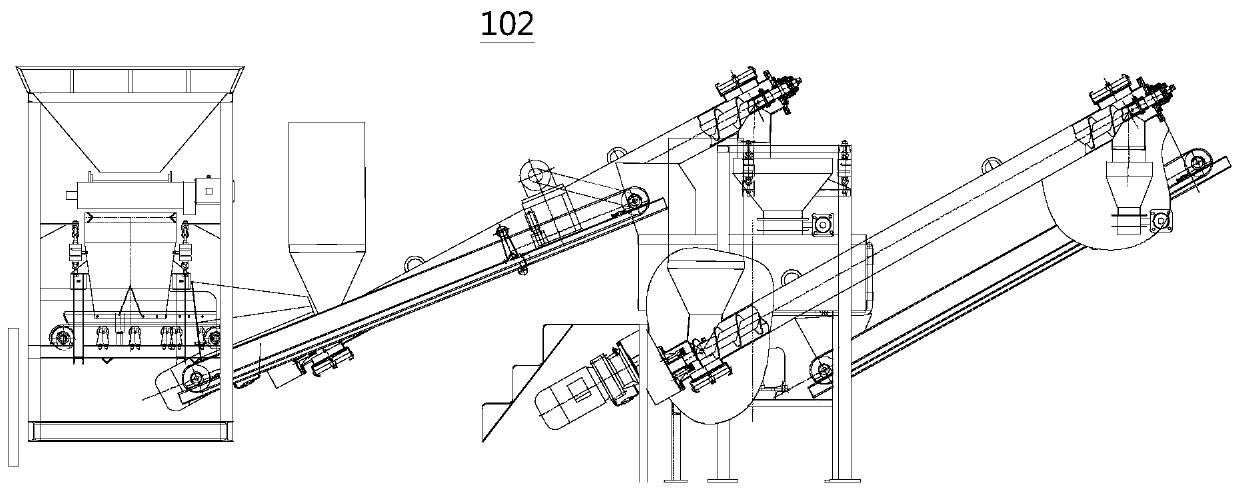

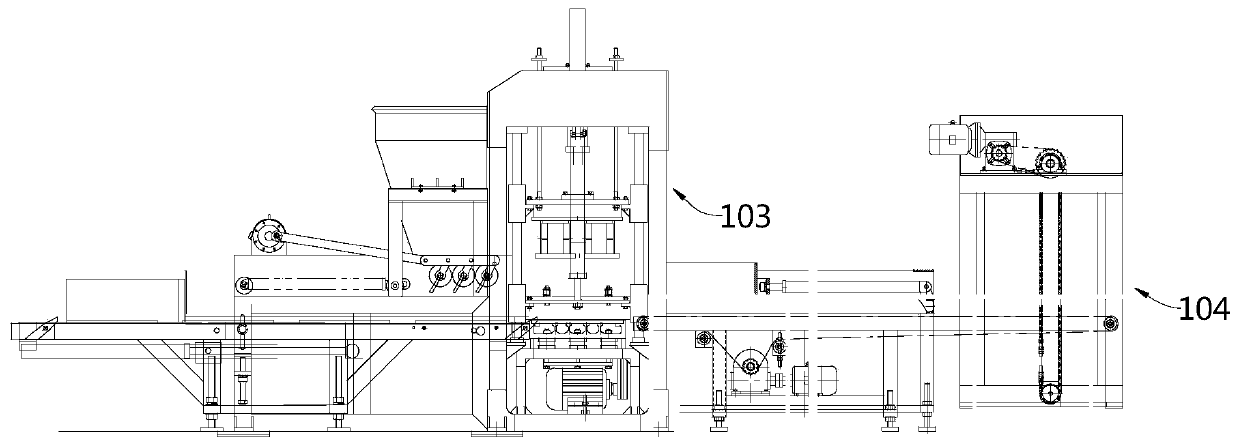

Recycled concrete product production equipment

A technology of recycled concrete and production equipment, which is applied in the direction of clay preparation equipment, auxiliary molding equipment, mixing operation control, etc., can solve the problems of inflexibility of concrete production lines, achieve the effect of reducing raw material transportation costs and avoiding flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the present application, the examples, implementations and features of the present application may be combined with each other under the condition of no contradiction or conflict. In this application, conventional equipment, devices, components, etc., can be purchased commercially, or can be self-made according to the content disclosed in this application. In this application, in order to highlight the key points of this application, some conventional operations, equipment, devices, and components are omitted or simply described.

[0034] Currently, concrete products are produced in fixed, factory-like production lines, which can cause problems in at least the following aspects:

[0035] 1. The cost of raw materials has increased a lot due to transportation costs.

[0036] 2. The sales radius of finished products is limited.

[0037] 3. The amount of labor required is large.

[0038] 4. Low degree of automation;

[0039] 5. The production line with a slightly hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com