Fiber resin composite and preparation method thereof

A fiber resin and composite technology, applied in the field of fiber resin composites and its preparation, can solve the problems of cumbersome preparation process and high cost of fiber reinforced composite materials, achieve the effect of reducing surface treatment process, reducing preparation cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

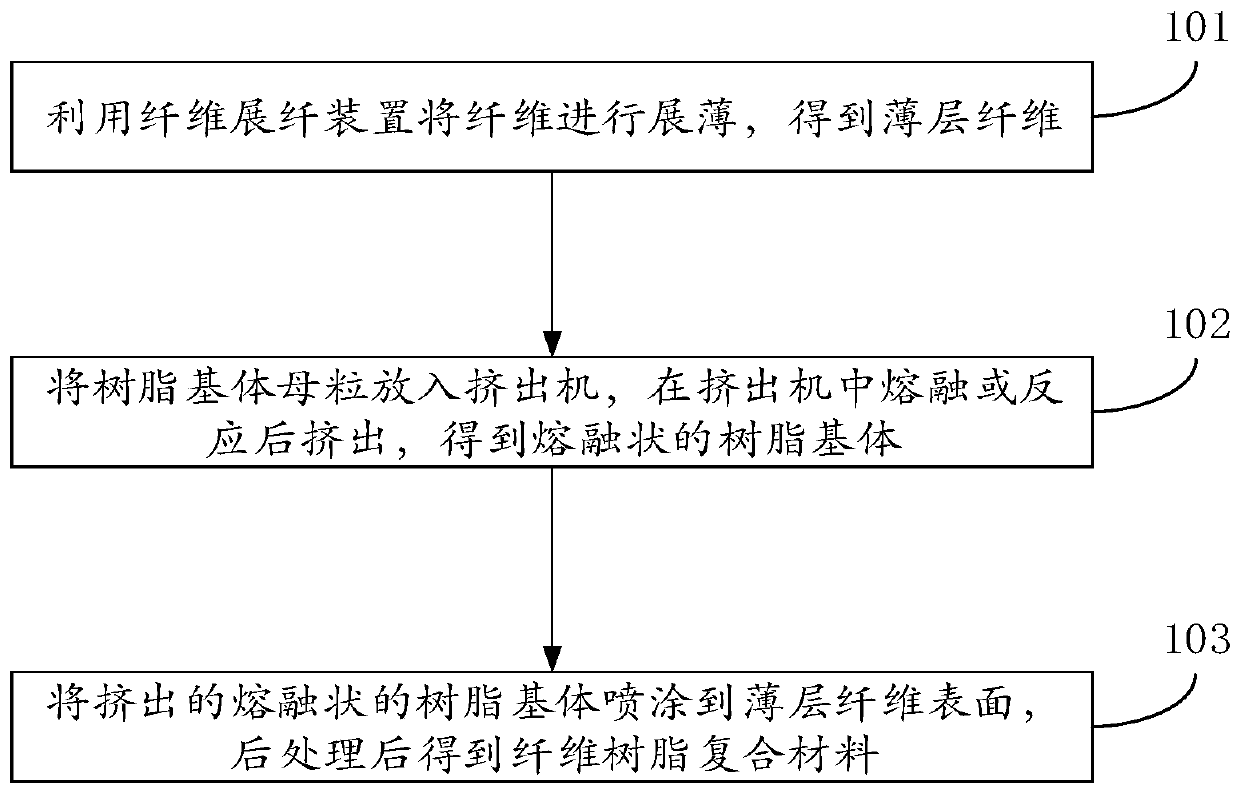

[0019] The embodiment of the present application provides a kind of preparation method of fiber resin composite, such as figure 1 As shown, the methods include:

[0020] Step 101, using a fiber spreading device to thin the fibers to obtain a thin layer of fibers;

[0021] In the embodiment of the present application, in the process of preparing the fiber-resin composite, in order to obtain a composite material with better performance, it is necessary to increase the contact area between the fiber and the resin material as much as possible. The fiber spreading device is used to thin the fiber, which can increase the surface area of the fiber, thereby increasing the contact area between the fiber and the resin material.

[0022] Step 102, put the resin matrix masterbatch into the extruder, melt or react in the extruder and then extrude to obtain the molten resin matrix.

[0023] In the embodiment of the present application, an extruder is used to melt or react the resin matr...

Embodiment 1

[0043]The carbon fiber is thinned to about 30 μm, and the polyamide resin is melted and extruded in the extruder at 350 °C, the receiving distance is controlled to be 10 cm, the flow rate of the polyamide resin matrix is 3 mL / min, and the hot air pressure is 0.3 MPa. The air temperature is 380°C, and the flow rate of the resin matrix is 900g / 10min. Under the above conditions, the extruded polyamide resin matrix is sprayed on the surface of the thin layer of carbon fibers to obtain a carbon fiber polyamide composite.

Embodiment 2

[0045] Thin the aramid fiber to about 30 μm, melt and extrude the polyamide resin in the extruder at 350°C, control the receiving distance to 10cm, the flow rate of the polyamide resin matrix to 3mL / min, and the hot air pressure to 0.3MPa , the temperature of the hot air is 380°C, and the flow rate of the resin matrix is 900g / 10min. Under the above conditions, the extruded polyamide resin matrix is sprayed on the surface of the thin layer of aramid fiber to obtain the aramid fiber polyamide composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com