An oil-electric hybrid power system for a coiled tubing operation vehicle

A technology of gasoline-electric hybrid power and work vehicles, which is applied in the direction of hybrid vehicles, power devices, air pressure power devices, etc., can solve the problems of low engine working efficiency, improve vehicle economy, enhance reliability, and shift gears less frequent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

[0026] The invention designs an oil-electric hybrid power system of a coiled tubing operation vehicle to overcome the disadvantage of low engine working efficiency when the coiled tubing operation vehicle is running, improve the economy of the whole vehicle, and realize It not only improves the rational utilization of energy, but also improves the power and reliability of the system.

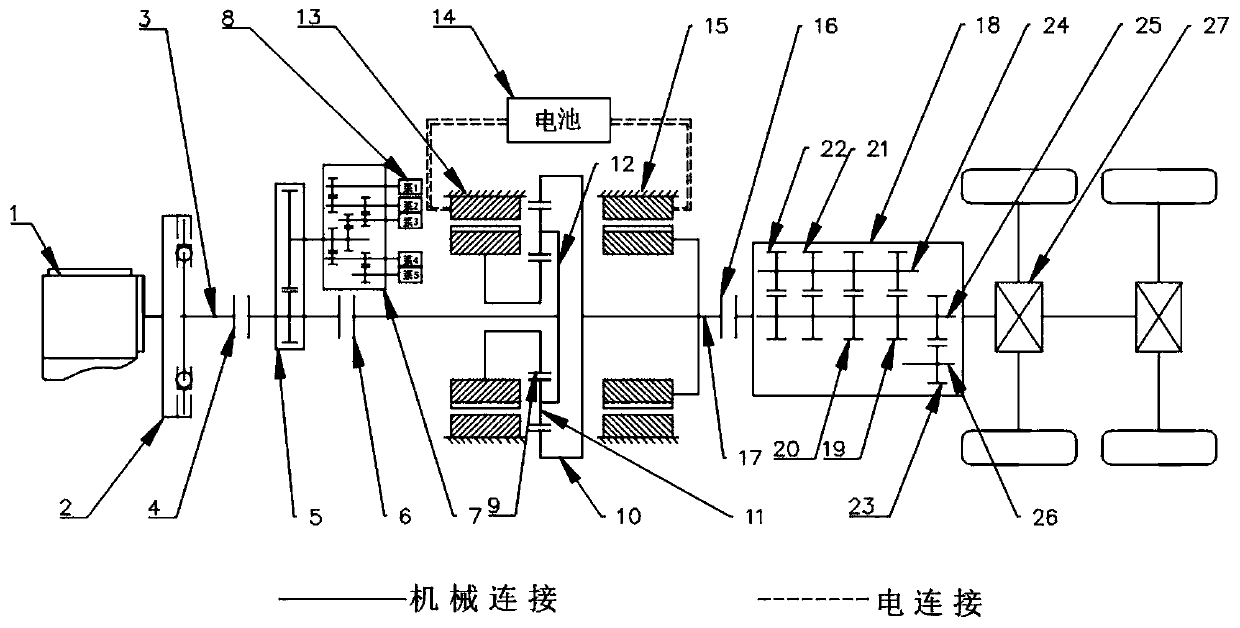

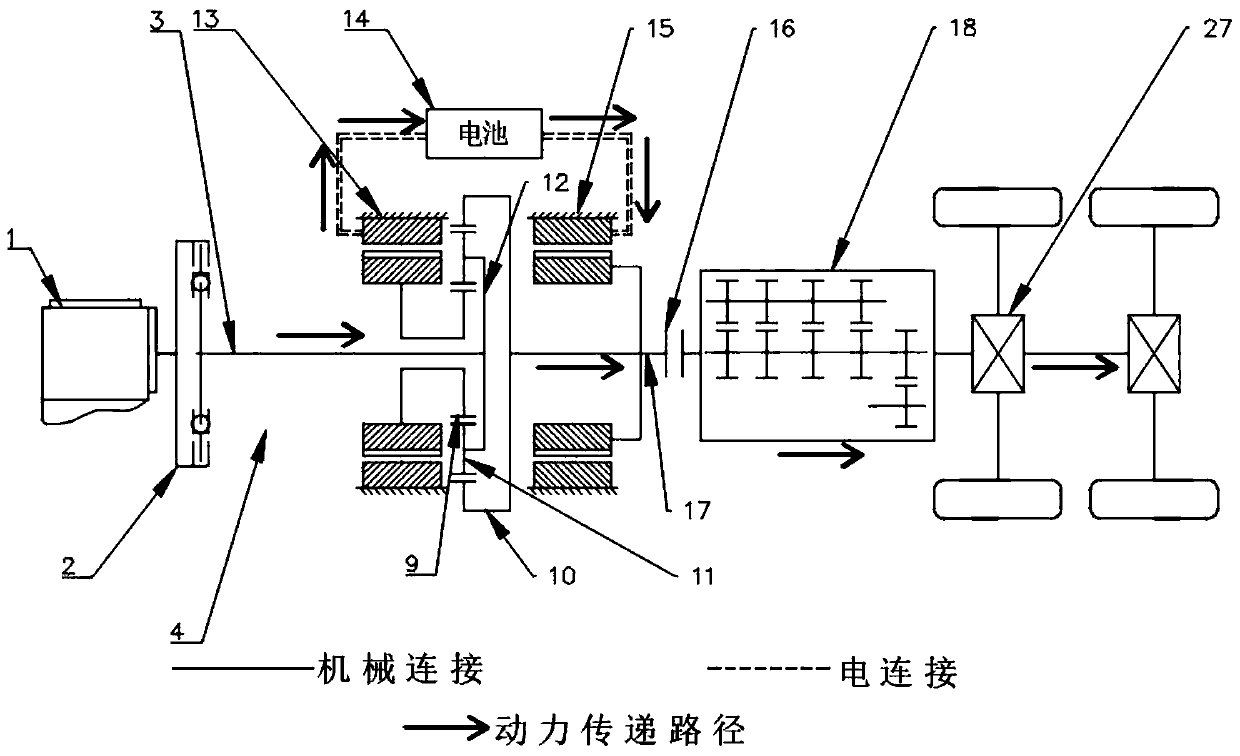

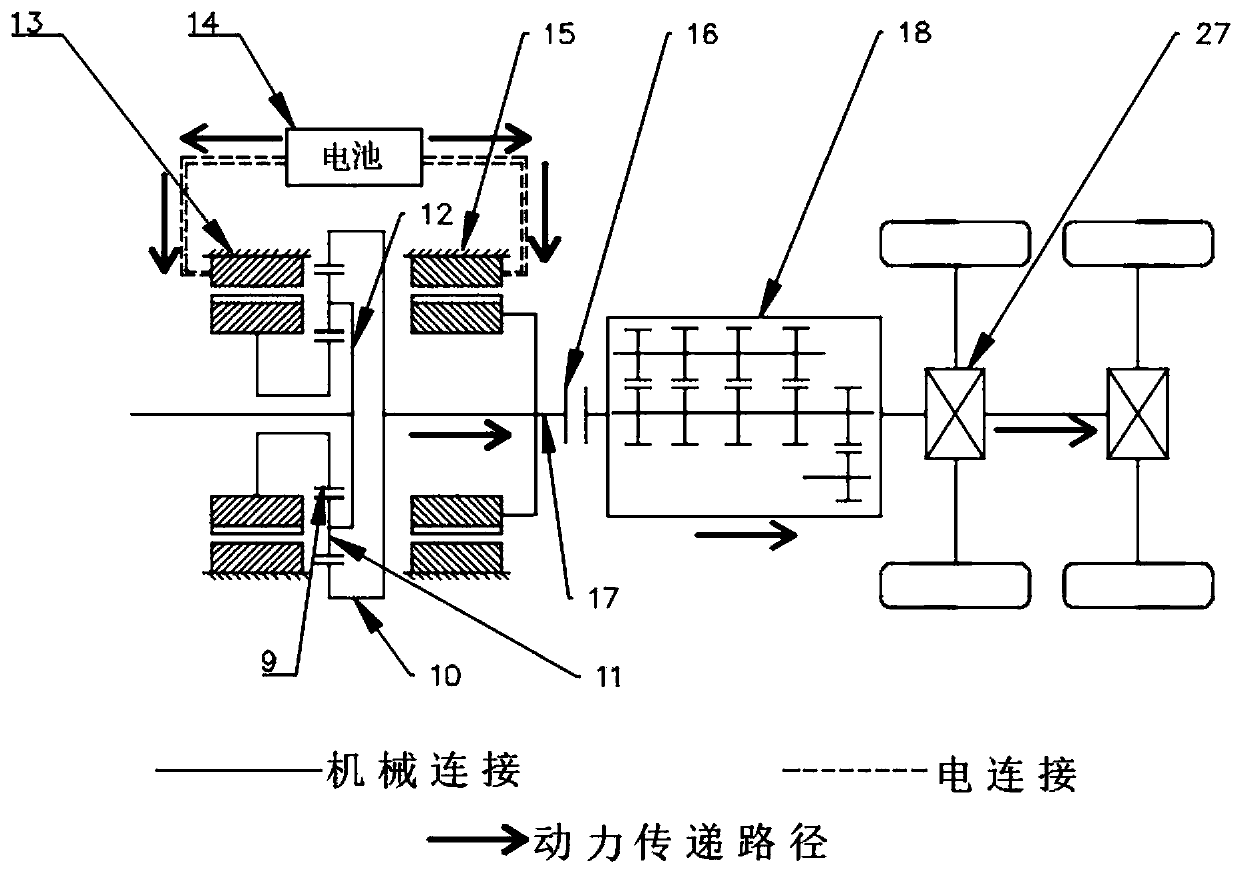

[0027] refer to figure 1 , the present invention designs a hybrid electric power system of a coiled tubing vehicle, and the hybrid power system of a coiled tubing vehicle includes an engine 1, a torsional shock absorber 2, a power take-off 5, and a transfer case 7 , hydraulic pump group 8, planetary row mechanism, clutch mechanism, motor device, four-speed transmission 18, battery 14 and rear axle 27; Wherein, hydraulic pump group 8 includes pump 1, pump 2, pump 3, pump 4 and pump 5; The plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com