A low-cost, high-efficiency alumina fiber-reinforced alumina composite material preparation method

A technology of alumina fiber and composite materials, applied in the preparation of high-efficiency alumina fiber-reinforced alumina composite materials, low-cost field, can solve the problems of unfavorable mechanical properties of composite materials, aggravation of alumina fibers, long preparation cycle, etc., to achieve excellent High-temperature mechanical properties and thermal stability, reduced thermal damage, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

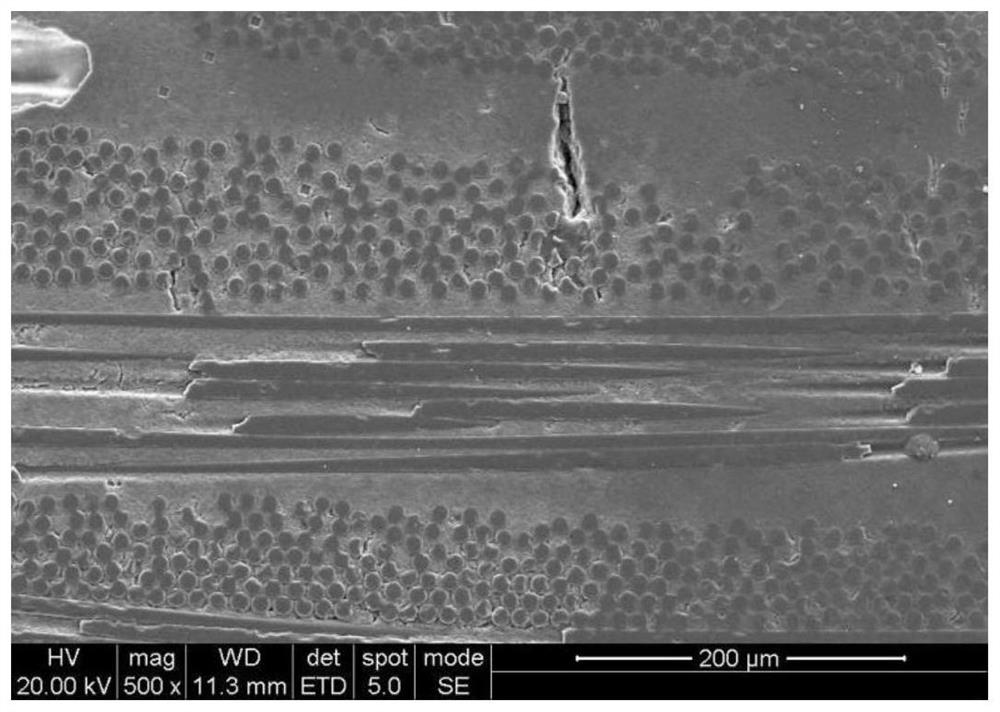

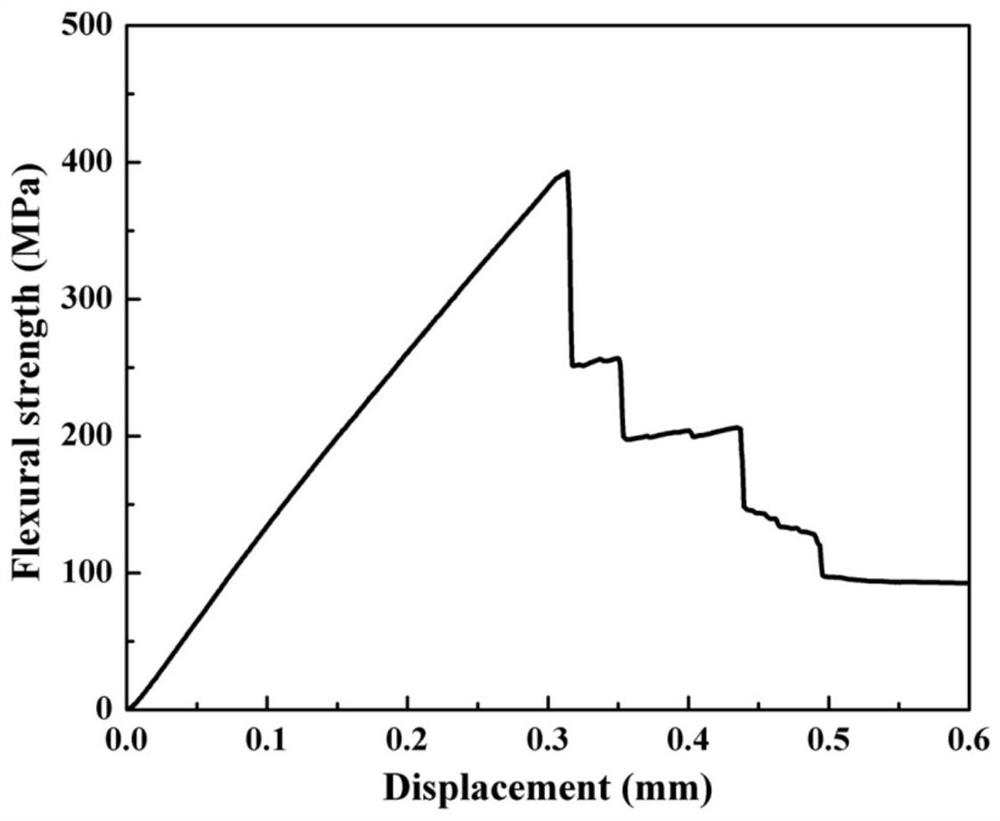

Image

Examples

Embodiment 1

[0028] A preparation method of low-cost, high-efficiency alumina fiber-reinforced alumina composite material, which specifically comprises the following steps:

[0029] (1) Disperse the alumina powder with an average particle size of 0.2 μm into deionized water, add nitric acid to adjust the viscosity and Zeta potential value of the slurry, and perform ball milling: the ball milling speed is 400 rpm, and the ball milling time is 2h to obtain alumina Slurry, the solid content of alumina powder in the alumina slurry is 55vol%, the viscosity of the alumina slurry is 150mPa·s, and the Zeta potential is 70mV;

[0030] (2) The alumina fiber cloth is cut into specifications, placed in a muffle furnace, heated to 600 °C in an air atmosphere, kept for 2 hours, and taken out with the furnace cooled to room temperature;

[0031] (3) Lay out the alumina fiber cloth obtained in step (2) in the mold, apply the alumina slurry obtained in step (1) on the surface of each layer of alumina fiber...

Embodiment 2

[0044] The present embodiment provides a low-cost, high-efficiency preparation method of alumina fiber-reinforced alumina composite material, which specifically includes the following steps:

[0045] (1) Disperse the alumina powder with an average particle size of 0.2 μm into deionized water, add ammonia water to adjust the viscosity and Zeta potential value of the slurry, and perform ball milling: the ball milling speed is 400 rpm, and the ball milling time is 4 h to obtain alumina Slurry, the solid content of alumina powder in the alumina slurry is 60vol%, the viscosity of the alumina slurry is 350mPa·s, and the Zeta potential is -38mV;

[0046] (2) The alumina fiber cloth is cut into specifications, placed in a muffle furnace, heated to 650°C in an air atmosphere, kept for 2 hours, and taken out with the furnace cooled to room temperature;

[0047] (3) Lay out the alumina fiber cloth obtained in step (2) in the mold, apply the alumina slurry obtained in step (1) on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com