Energy gathering disc with combustion function and gas stove comprising same

An energy-gathering plate and functional technology, applied in the field of kitchen utensils, can solve the problems of low heating efficiency and low gas combustion efficiency of gas stoves, and achieve the effects of ensuring stability and sufficiency, increasing heating range, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In the following, the present invention will be more clearly and completely described by means of an embodiment in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiment.

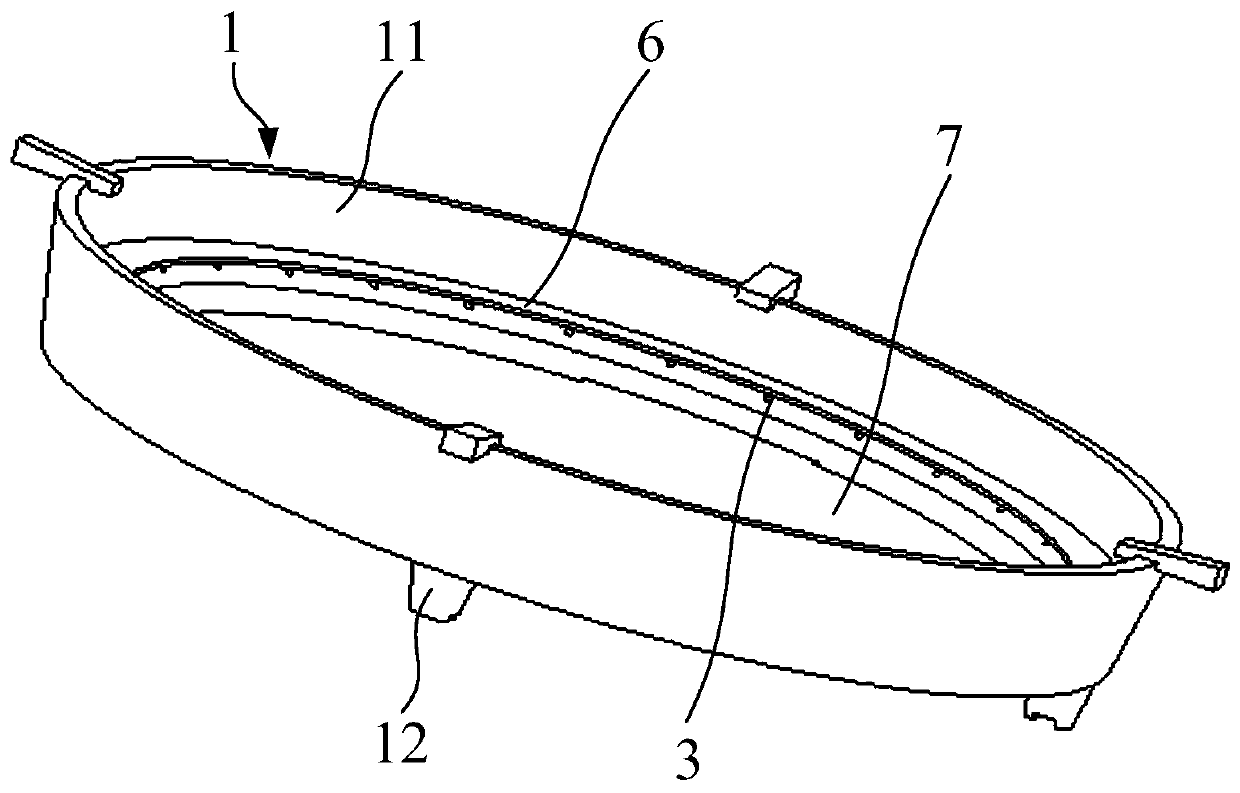

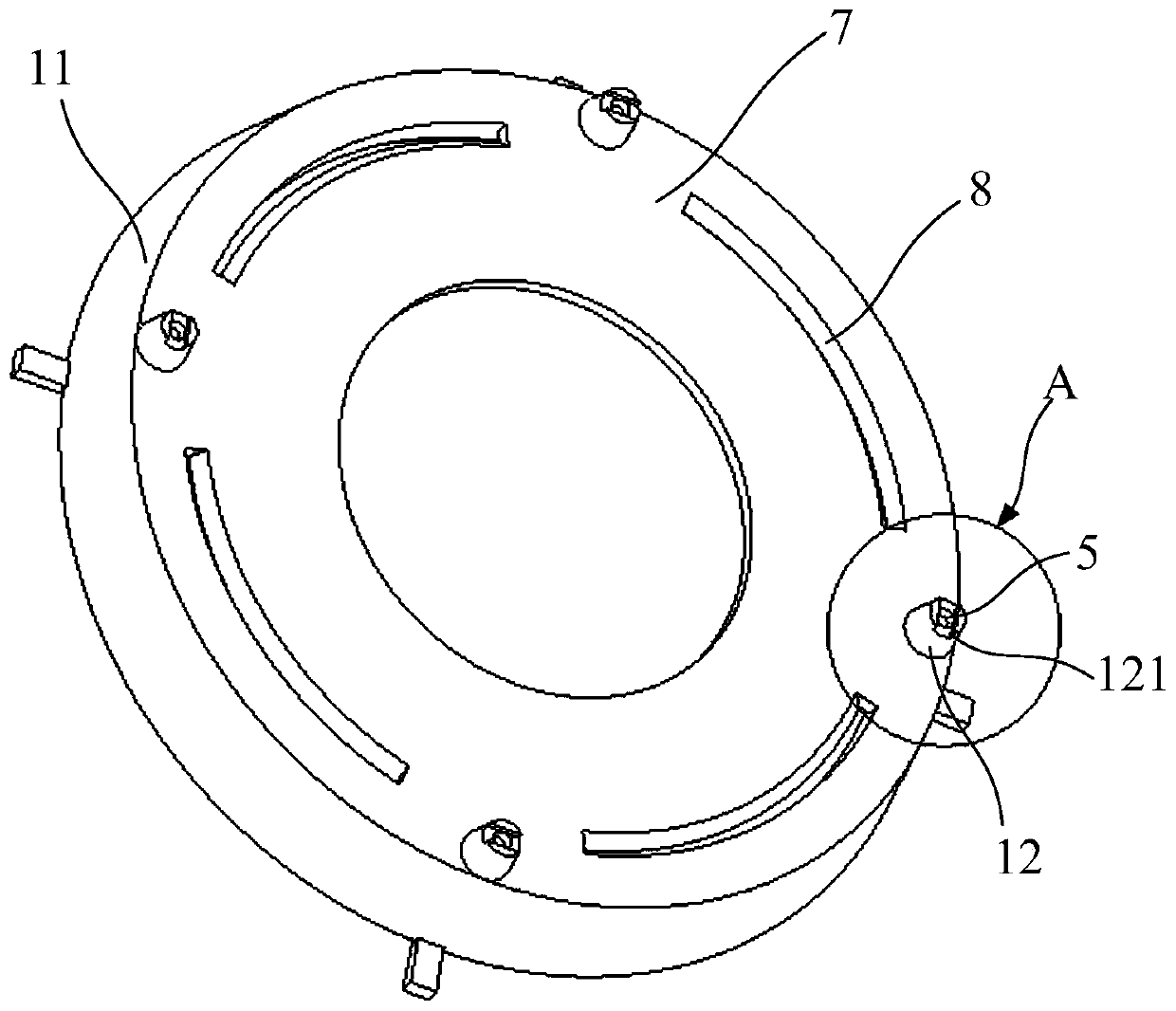

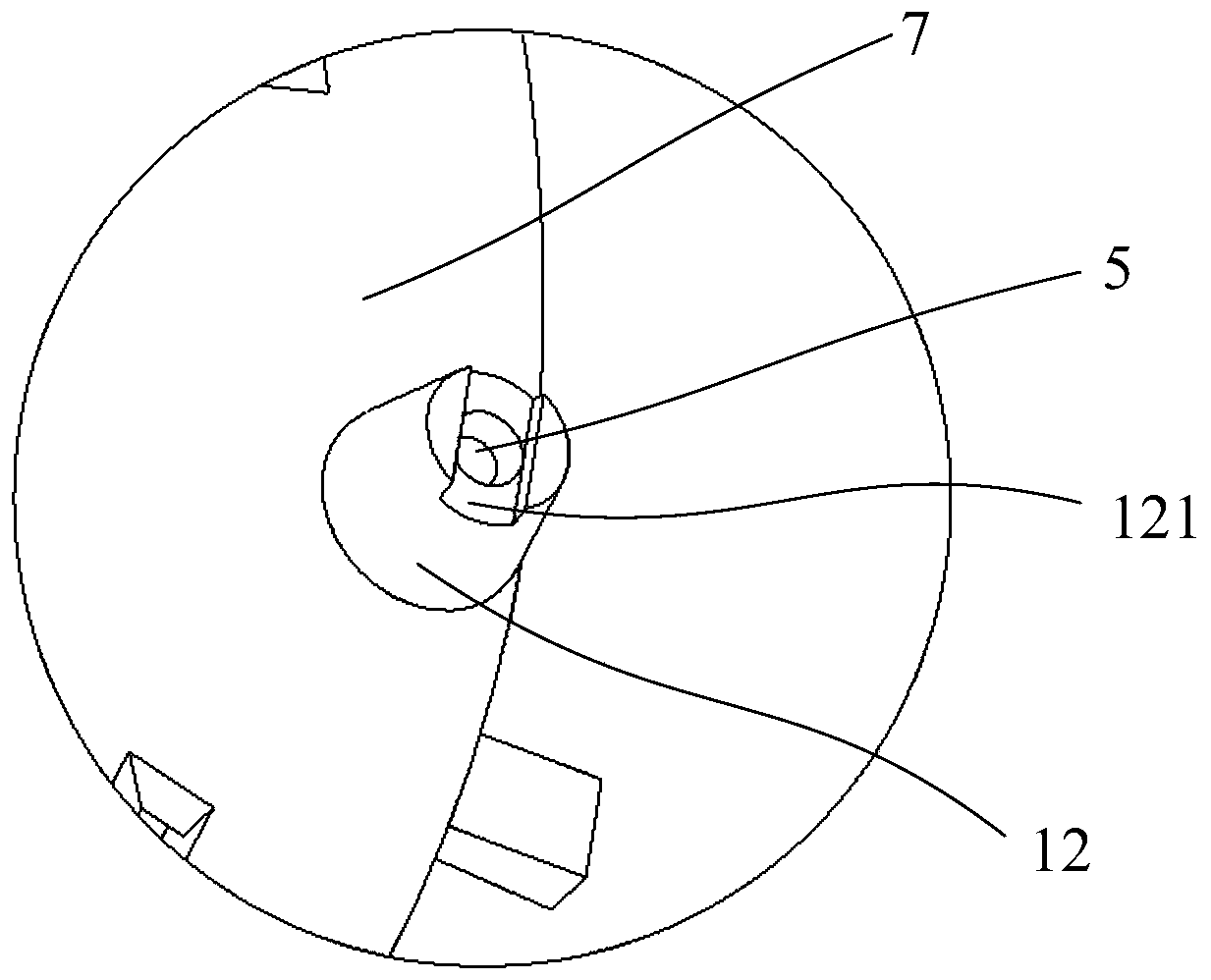

[0059] Such as Figure 1-4 As shown, the present invention provides a kind of energy collecting plate with combustion function, the energy collecting plate 1 has an energy collecting ring wall body 11, the inside of the energy collecting ring wall body 11 is provided with an annular gas mixing chamber 2, along the energy collecting ring The inner wall of the wall body 11 is provided with a plurality of fire holes 3 in the circumferential direction, and the circumferential direction of the annular gas mixing chamber 2 is provided with a plurality of gas outlet passages 4 corresponding to and communicating with the plurality of fire holes 3. The annular gas mixing chamber 2 The lower end is provided with several injection channels 5 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com