COF Film production method and vertical oven

A production method and vertical technology, applied in lighting and heating equipment, coating, drying and other directions, can solve problems such as ICBumpOpenICBumpShort defect, achieve the effect of overcoming uneven heating and reducing defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

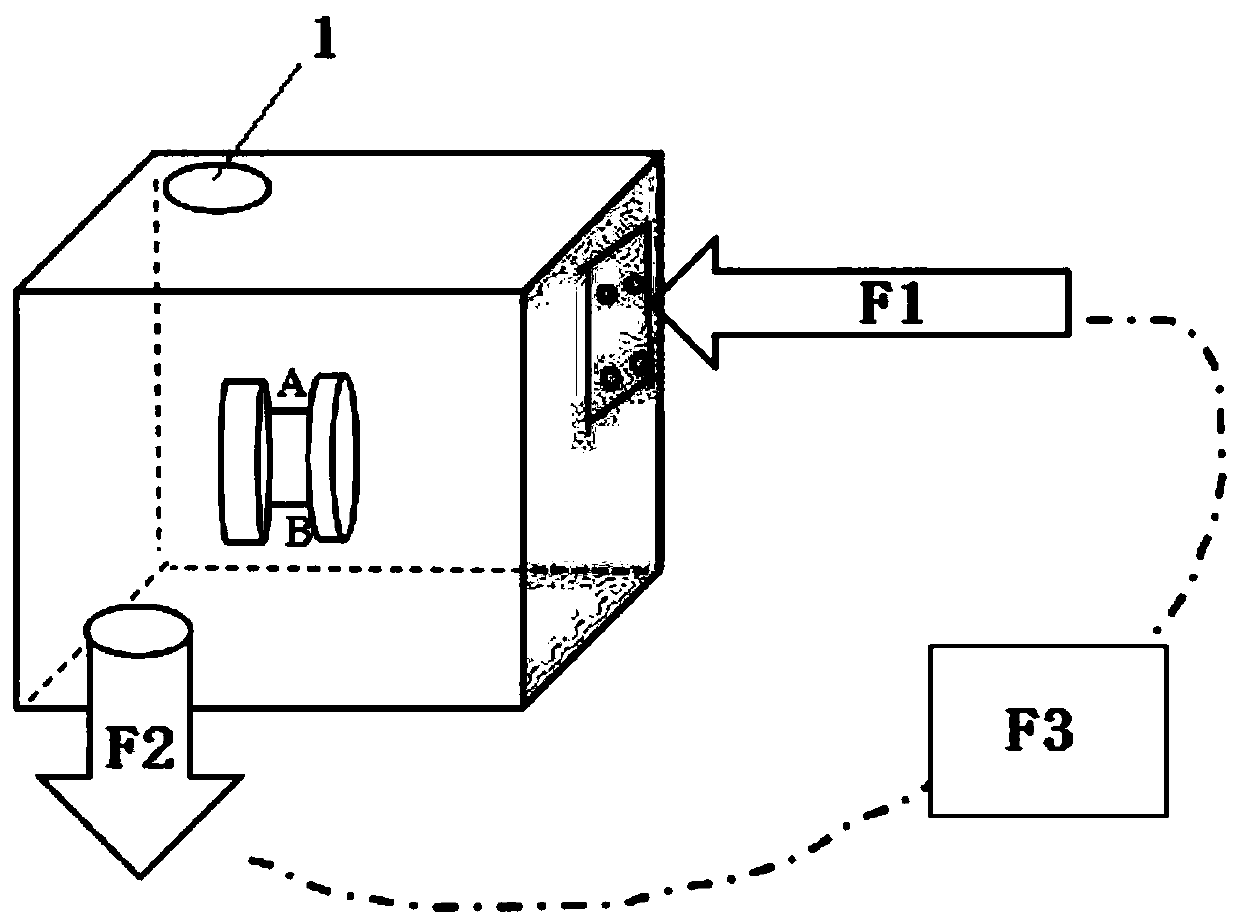

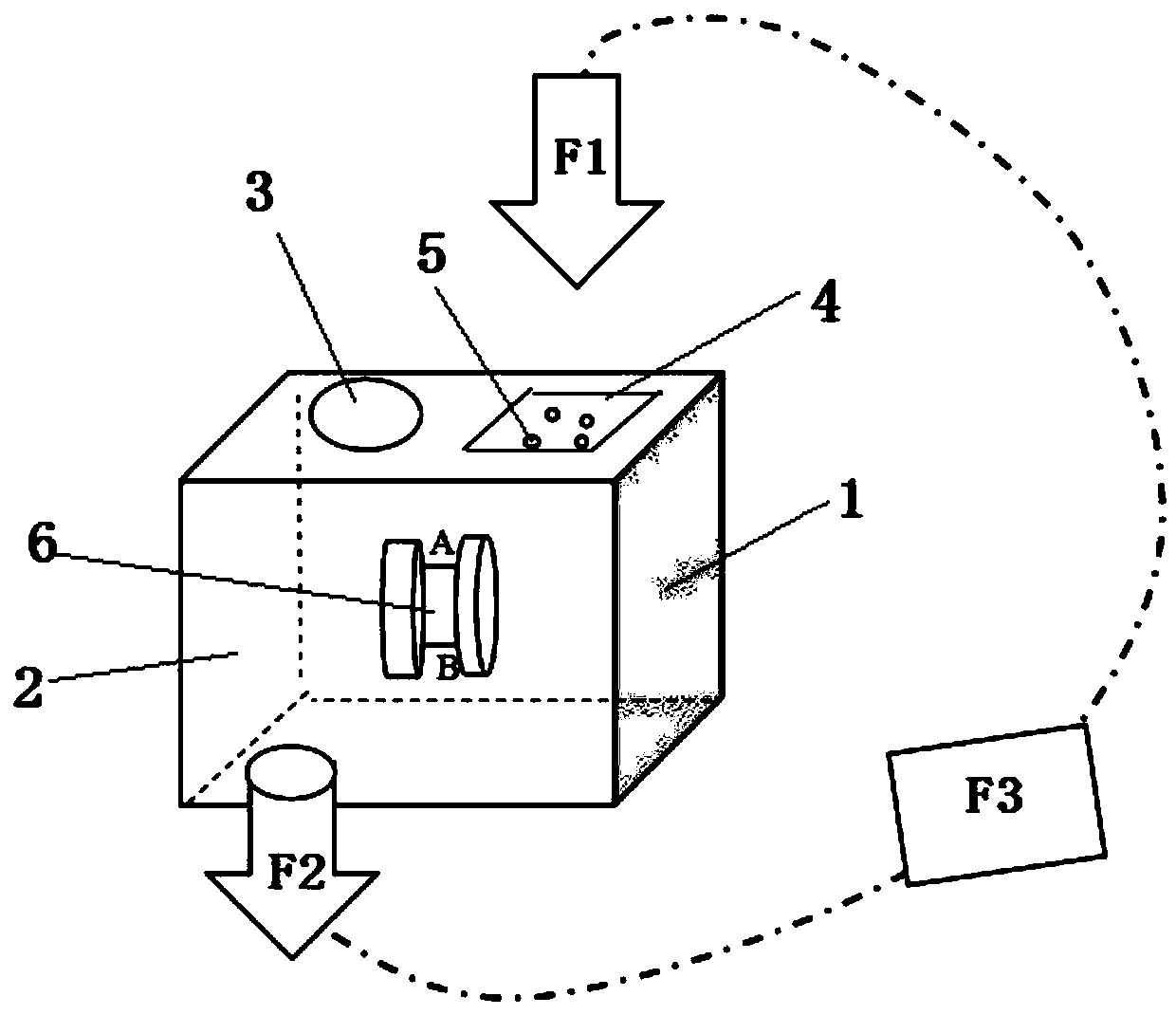

[0024] Such as figure 2 , a kind of upright oven, comprises oven 1, and this oven 1 is made up of box top, box bottom, left box side, right box side, front box side and back box side, box top, box bottom, left box side, right box side, The front box side and the rear box side form a cavity 2, an air inlet area 4 is arranged on the top of the box, an air inlet 5 is arranged in the air inlet area 4, and an air inlet 3 is arranged on the top of the box, and the air inlet 3 is located at the air inlet outside area 4.

[0025] In this embodiment, it should be further noted that the air inlet area 4 is preferably square.

[0026] In this embodiment, it should be further explained that the area of the air inlet 3 is larger than the area of the air inlet 5 .

[0027] In this embodiment, it should be further noted that the air inlet 5 may be square, circular or oval.

[0028] In this embodiment, it should be further noted that the air outlet 3 may be square, circular or oval. ...

Embodiment 2

[0035] Embodiment 2 temperature uniformity test in the oven

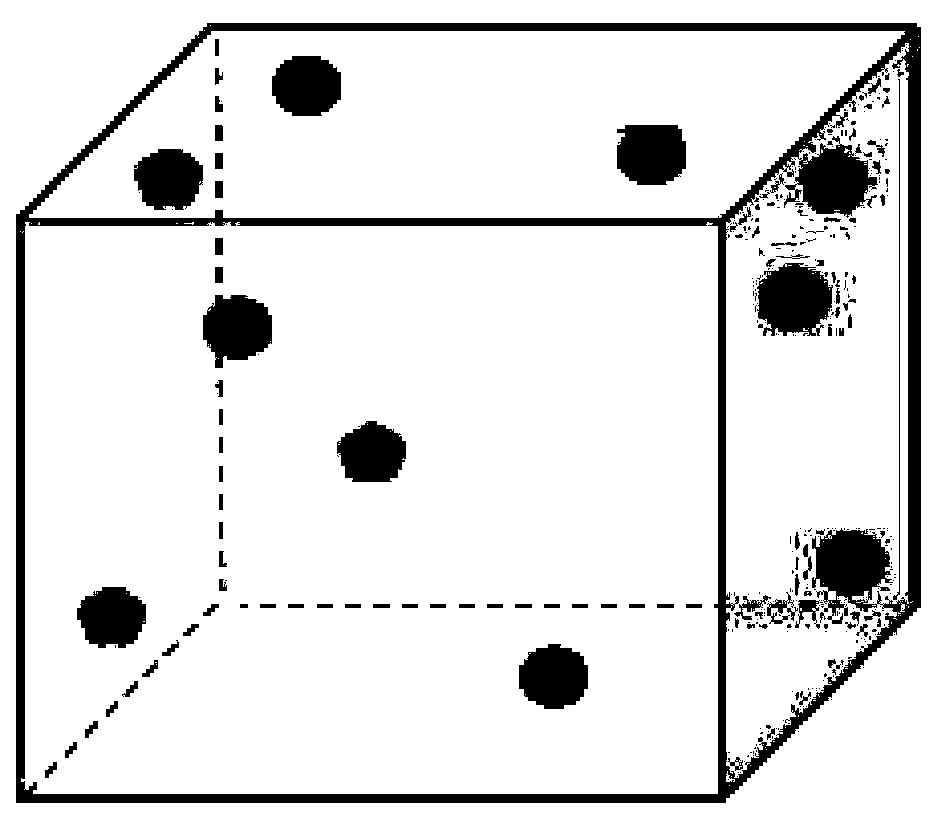

[0036] Respectively to embodiment 1 (at this time, the air inlet and the air inlet are circular, and the area of the air inlet is larger than the area of the air inlet) and comparative example 1 (at this moment, the air outlet and the air inlet are all circular, and the area of the air outlet is larger than Air inlet area) vertical oven to test the temperature uniformity in the oven, 120°C is the set temperature, and the distribution of test points is as follows: image 3 (The positions of the detection points of the two ovens are the same, and the temperature sensors are placed at the detection points. Except for the bottom surface, there are two temperature sensors on each of the other surfaces, which are in diagonal positions, and the two adjacent surfaces are staggered. There are 10 Sensors in total. Each detection Each point has been measured 3 times), and the test results are as follows in Table 1:

[0...

Embodiment 3

[0042] Embodiment 3 reduces defective rate

[0043] The ovens of Example 1 and Comparative Example 1 were used for the production of COF Film respectively, except that the ovens were different, all the other production process conditions and equipment were the same, and the produced COF Film product rolls were subjected to quality inspection (IC Bump Open and IC Bump Short detection), the detection results are as follows in Table 3:

[0044] Table three

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com